Transmission shaft flange grinding device for machining mechanical parts

A technology for mechanical parts and transmission shafts, applied in the field of transmission shaft flange grinding devices, can solve the problems of poor fixation stability, low efficiency, and inability to realize harmful gas absorption and purification in linkage, and achieve the effect of improving the expansion and contraction range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

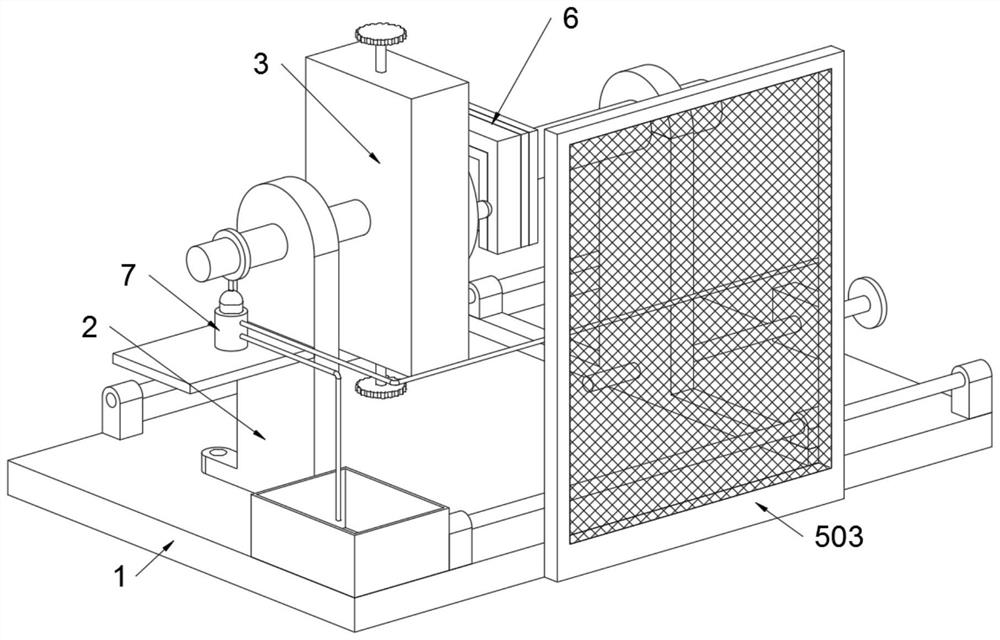

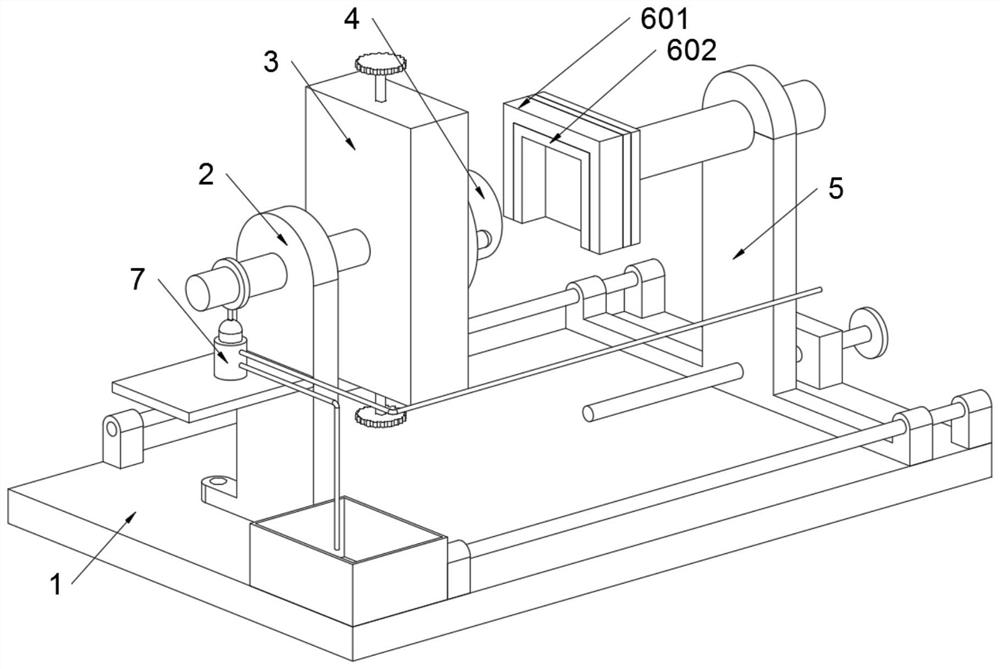

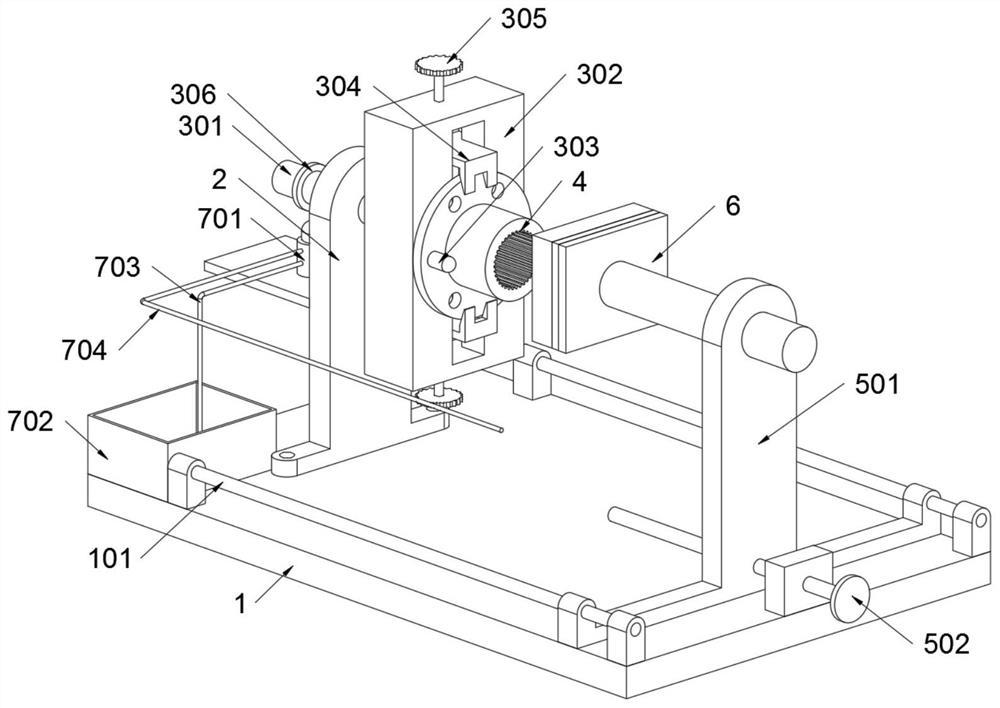

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The invention provides a transmission shaft flange grinding device for processing mechanical parts, comprising a base 1 and an elastic telescopic bottle 701; the base 1 is fixedly connected with a mounting seat 2 by bolts, and the mounting seat 2 is rotatably connected with a fixed Structure 3, and the transmission shaft flange 4 is fixed on the fixed structure 3; the adjustment structure 5 is arranged on the base 1, and the grinding structure 6 is welded on the adjustment structure 5; the purification structure 7 is installed on the mounting base 2; refer to as figure 2 and image 3, the grinding structure 6 includes a grinding seat 601 and a grinding block 602, the grinding seat 601 is welded on the main body seat 501, and a grinding block 602 is adhered in the grinding seat 601; both the grinding seat 601 and the grinding block 602 are concave structures, and the grinding Block 602 inner wall is in contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com