Flexible hot-pressing device for adhesion of secondary screen wall of Mark type cargo containment system and hot-pressing method of flexible hot-pressing device

A hot pressing device and secondary screen technology, applied in the field of flexible hot pressing devices, can solve the problems of extremely high flatness, lack of glue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

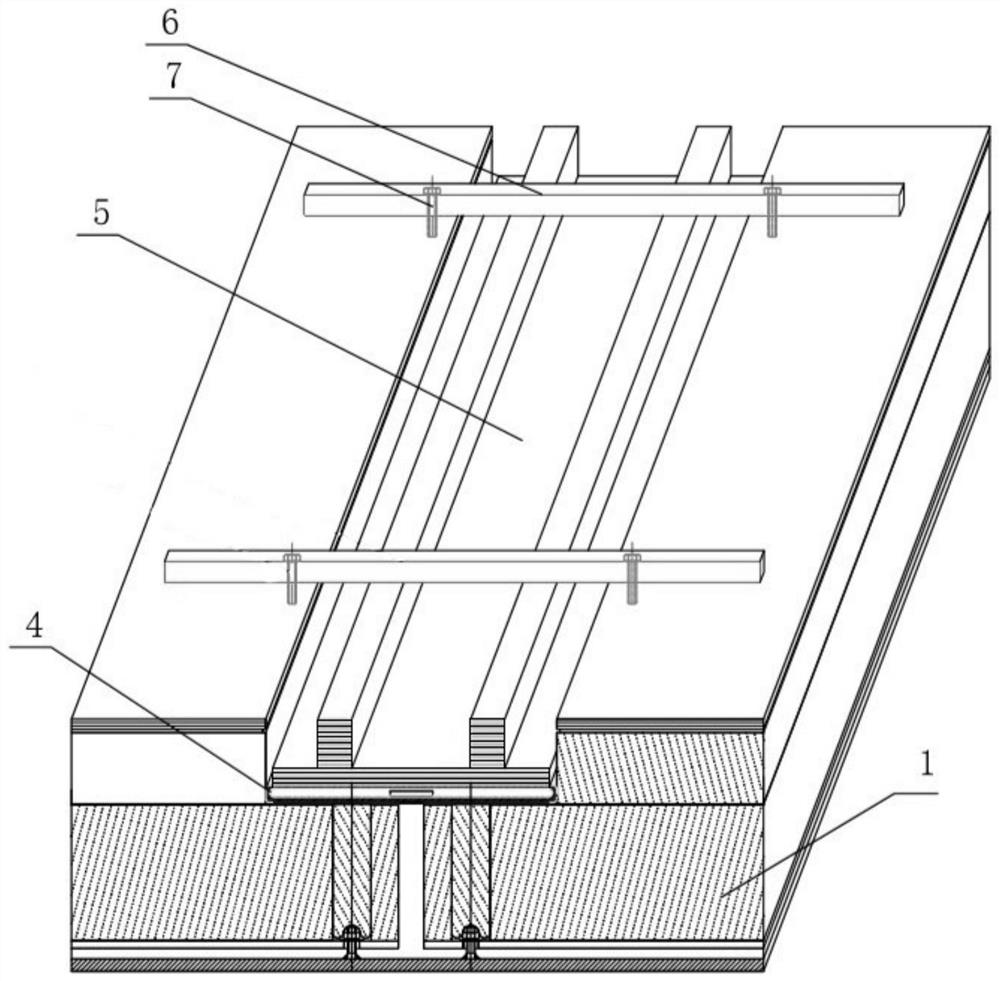

[0051] After the applicant's research and analysis, the reason for this problem (now due to the local lack of glue and the formation of degumming defects when the hot-pressing device is hot-pressing the secondary barrier layer) is that the traditional process method uses two pieces The air bag or liquid bag between the pressure plates forms a uniform pressure on the contact surface, and at the same time, a temperature-controllable heating sheet composed of heating wire is arranged on the contact surface to provide a set temperature. This technical solution has extremely high requirements on the flatness of the surface to be adhered and the flatness of the pressure plate. Once the surface of the pressure plate on the contact surface with the secondary barrier layer is uneven, due to the self-adaptive balance of the air bag or liquid bag, the pressure plate will Inclination occurs to adapt to the unevenness of the surface of the pressure plate, and the inclination of the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com