E420-W300 ultrahigh-strength ship plate steel and manufacturing method therefor

A manufacturing method, ship plate steel technology, applied in the field of iron and steel production, can solve problems such as lowering the mechanical properties of welded joints, deterioration of low-temperature toughness, etc., and achieve the effects of reducing costs, stabilizing the production process, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

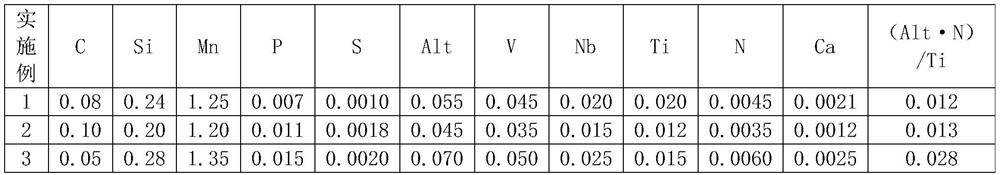

[0026] A kind of E420-W300 ultra-high-strength ship plate steel and its manufacturing method provided in the following examples, the steel plate thickness is 80mm, the chemical composition is shown in Table 1, the rolling cooling process parameters are shown in Table 2, and the product performance is shown in Table 3:

[0027] The main chemical composition (wt%) of the embodiment of table 1

[0028]

[0029] The rolling cooling process parameter of table 2 embodiment

[0030] Example Thickness mm Rough rolling finish temperature ℃ Finish rolling start temperature ℃ Return to red temperature ℃ 1 80 1071 845 560 2 80 1052 818 500 3 80 1083 867 600

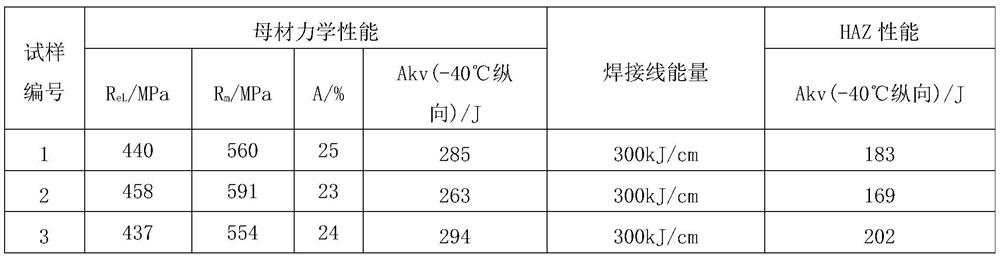

[0031] Table 3 embodiment product performance

[0032]

[0033] It can be seen that the steel plate obtained by the present invention has good comprehensive mechanical properties, yield strength ≥ 420MPa, tensile strength ≥ 530MPa, and is suitable for high-strength ship plate steel wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com