Preparation method of chemical fiber pulp

A technology of chemical fiber and pulp, which is applied in the field of chemical fiber pulp preparation, can solve the problems of ignoring the characteristics of raw pulp, lack of whiteness of chemical fiber pulp, etc., and achieve the effect of solving physical stability problems, reducing losses, and making up for whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing chemical fiber pulp, comprising the following steps:

[0024] S1, raw material preparation: cut sugarcane, reed, Miscanthus, coniferous wood and hardwood into 3 centimeters as raw materials for pulping, and remove impurities and soil on the raw materials for pulping;

[0025] S2. Initial bleaching: Pour pulping raw materials into hot water at 45°C, add bleaching agent, stir and cook for 30-45 minutes;

[0026] S3. Squeeze washing: Squeeze and wash the bleached crude fibers to separate fibers and non-fibrous substances, and the squeezed water flows into the sedimentation tank;

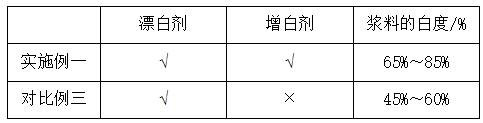

[0027] S4, secondary bleaching: add bleaching agent to the pulp washed pulp again, and add anti-flocculation agent and VBL brightener, and make the pulp into fine fiber pulp by refining;

[0028] S5. Pulping: the fine fiber pulp was subjected to an acid treatment for 45 minutes in an environment with an acid concentration of 2.0 g / L, followed by papermaking to obtain chemi...

Embodiment 1

[0031] S1, raw material preparation: cut sugarcane, reed, Miscanthus, coniferous wood and hardwood into 3 centimeters as raw materials for pulping, and remove impurities and soil on the raw materials for pulping;

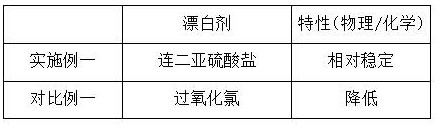

[0032] S2. Initial bleaching: Pour pulping raw materials into hot water at 45°C, add dithionite bleaching agent, stir and cook for 30 minutes;

[0033] S3. Squeeze washing: Squeeze and wash the bleached crude fibers to separate fibers and non-fibrous substances, and the squeezed water flows into the sedimentation tank;

[0034] S4. Secondary bleaching: add dithionite bleaching agent to the pulp washed pulp again, and add deflocculating agent and VBL whitening agent, and make the pulp become fine fiber pulp by refining;

[0035] S5. Pulping: the fine fiber pulp was subjected to an acid treatment for 45 minutes in an environment with an acid concentration of 2.0 g / L, followed by papermaking to obtain chemical fiber pulp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com