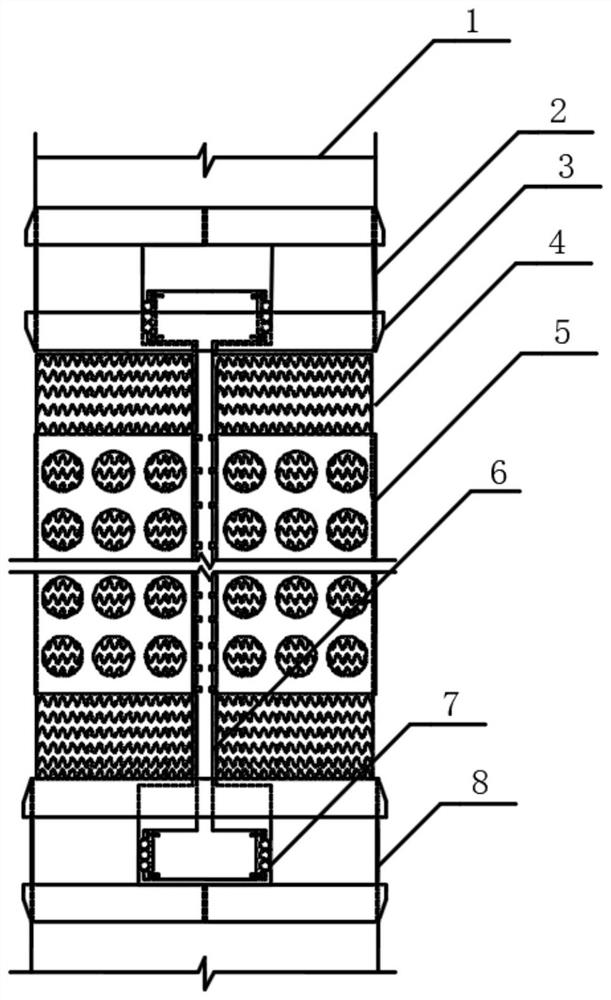

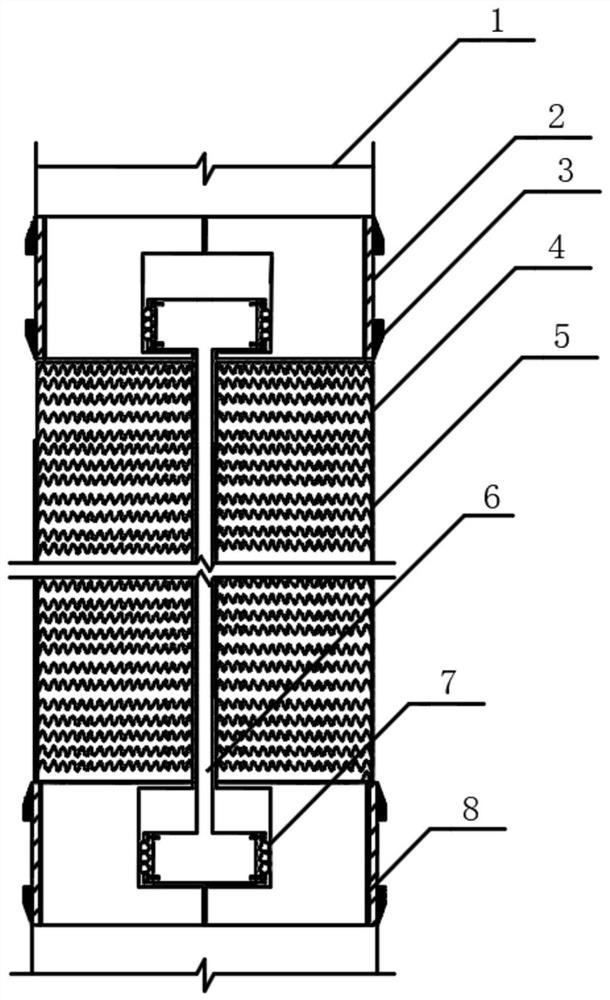

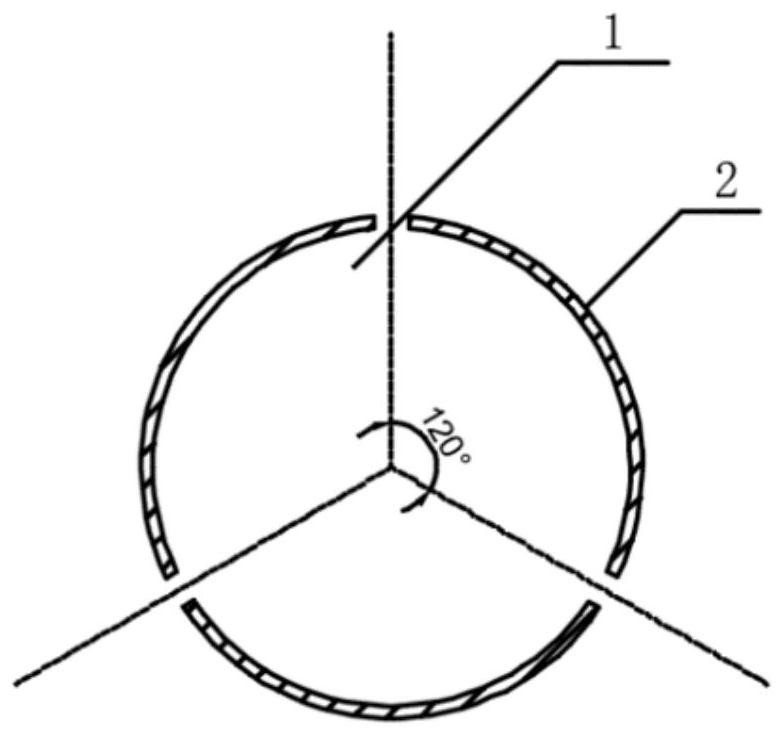

Device for negative friction resistance reduction and positive friction resistance transmission of precast pile and using method

A technology of negative friction resistance and prefabricated piles, which is applied in the direction of sheet pile wall, foundation structure test, construction, etc. Friction resistance, economic waste and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] It is known that the composite foundation adopts prefabricated tubular pile foundation, rock-socketed piles, diameter 400mm, length 24m, pile spacing 1.5m, upper load 150kPa, pile-soil stress ratio n=8, groundwater is located 1.0m below the ground.

[0101] Parameters of deep soft soil layer: thickness 10m, gravity γ s =18kN / m 2 , saturation gravity γ sat =19.2kN / m 2 , internal friction angle φ=10°, compression modulus E s = 3MPa.

[0102] calculation steps:

[0103] (1) Earth pressure on pile top plane

[0104]

[0105]

[0106] (2) Ultimate frictional resistance and plastic zone of pile side

[0107] At the top of the pile: τ u1 =0.6×(10+86.8tan10)=15.2kPa

[0108] z=1.2m, τ u2 =0.6×(10+65.6tan10)=12.9kPa

[0109]

[0110] That is, the depth of the plastic zone is 1.2m, and the limit value of negative friction resistance is 14.1kPa.

[0111] When the depth z=5.2m, σ sz ≥0.2σ cz

[0112]

[0113] The elastic zone is 1.2m to 5.2m deep and 4m lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com