Exterior wall external insulation structure and construction process

A technology of external wall insulation and construction technology, which is applied in thermal insulation, building components, building structures, etc., and can solve problems such as poor use effect and rainwater leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

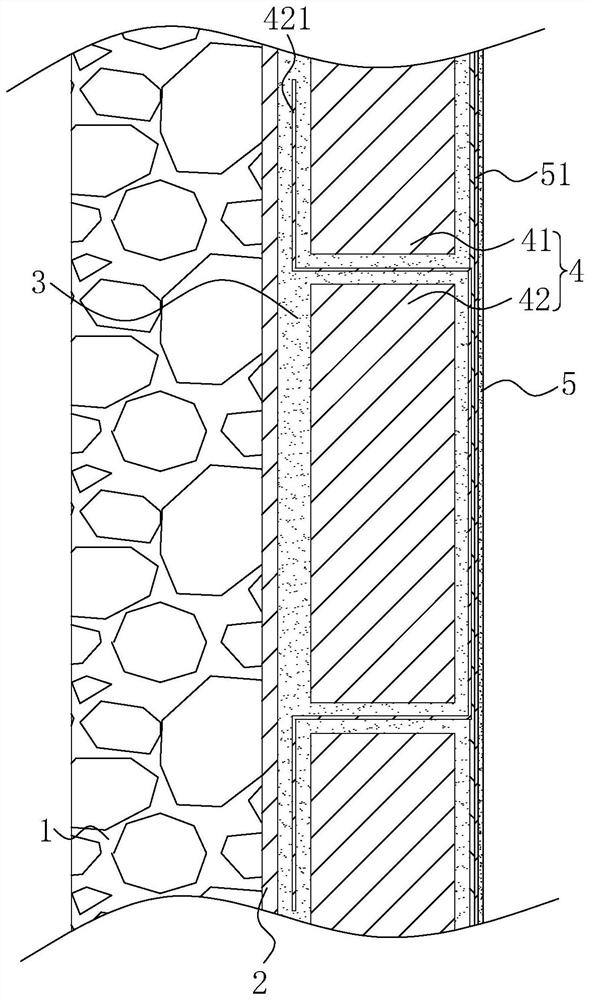

[0044] Embodiment 1, with reference to figure 1 , the thermal insulation structure includes a plaster layer 2, an adhesive layer 3 made of an adhesive, an thermal insulation layer 4 and a protective surface layer 5, which are sequentially stacked from the outer surface of the main body of the outer wall 1 outward. The protective surface layer 5 is preset with a first glass fiber mesh cloth 51 for strengthening its overall strength and integrity. Wherein, the protective surface layer 5 is formed by applying anti-crack mortar or plastering glue to the insulation layer 4 .

[0045] The insulation layer 4 includes a plurality of insulation boards 41 coated on the adhesive layer 3 and a fireproof isolation belt 42 arranged at the position of the structural floor. The fireproof isolation belt 42 is a plate-shaped structure made of a flame-retardant material, such as a rock wool board. The upper and lower edges of the fireproof isolation belt 42 and the surface away from the outer w...

Embodiment 2

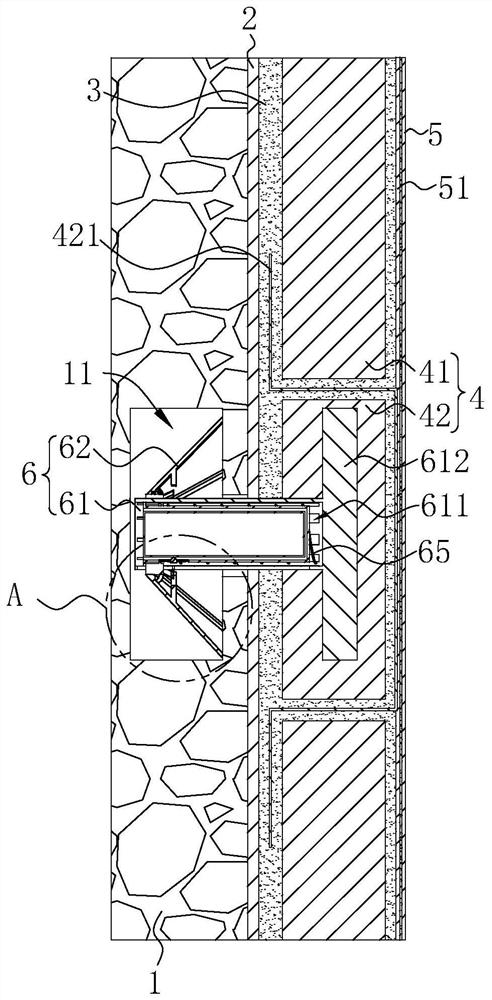

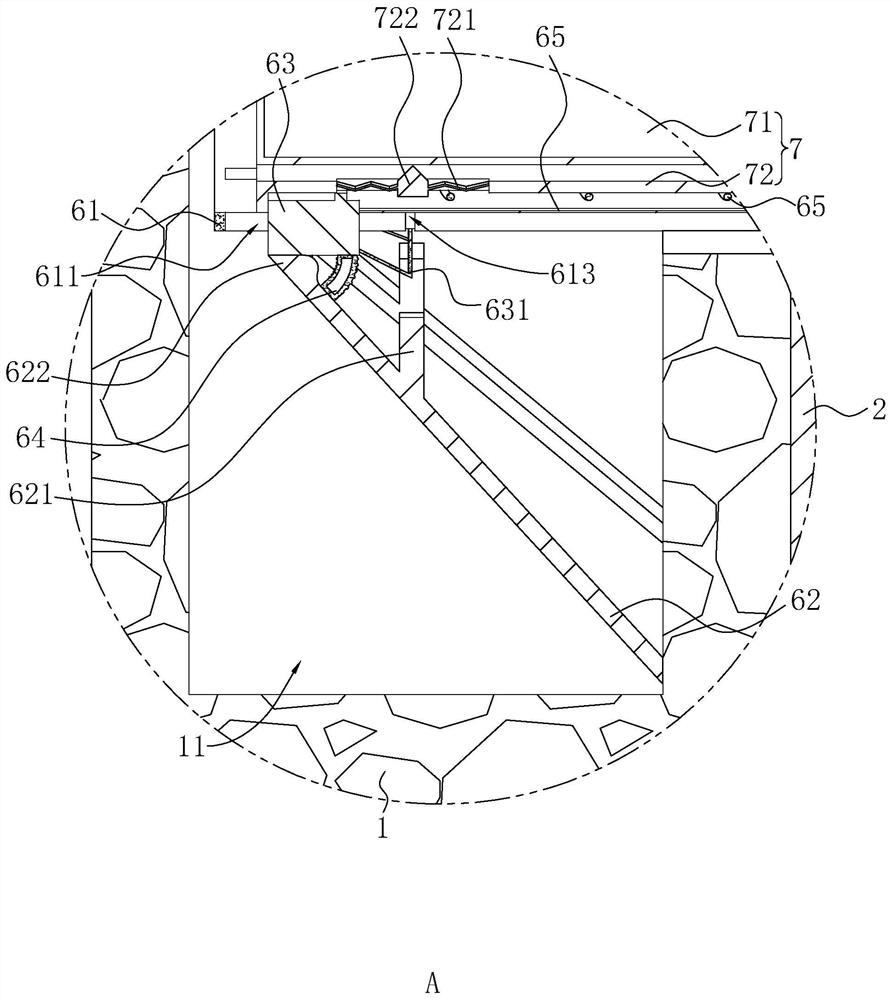

[0048] Embodiment 2, with reference to figure 2 and image 3 , the difference from Embodiment 1 is that a fixing mechanism 6 for strengthening the connection strength between it and the main body 1 of the outer wall is provided in the fireproof isolation belt 42 .

[0049] The fixing mechanism 6 includes a fixing tube 61 preset in the fireproof isolation belt 42 and a plurality of fixing pins 62 arranged around the fixing tube 61 , and a plurality of sliding openings 611 respectively extending along the axial direction of the fixing tube 61 are opened around the fixing tube 61 . The sliding port 611 is slidably connected with the sliding block 63, that is, the sliding block 63 is parallel to the axial side wall of the fixed tube 61 and provided with a chute extending in the axial direction of the fixed tube 61, and the sliding port 611 is parallel to the axial opening of the fixed tube 61 The edges are clamped and slidably connected in different sliding grooves, so that the ...

Embodiment 3

[0060] Embodiment 3, with reference to Figure 5 , the embodiment of the present application also discloses a construction process of an external wall thermal insulation structure, the construction process includes the following steps:

[0061]S1. Preliminary preparation: material preparation: measure and calculate the quantity of main and auxiliary materials related to fire protection belts, lines, and insulation, prepare plans and purchase materials; prepare construction machinery and tools; prepare and adjust before construction: pull the scaffolding on the wall horizontally. Move it to the position of the opening of the door and window, block the opening of the scaffolding horizontally and then paint it smooth before the construction of external insulation;

[0062] S2. Construction of fireproof isolation belt: pop up two horizontal closed lines with a spacing of 300mm along the position of the structural floor on the outer wall of the main body 1 of the outer wall, paste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com