Cooling-to-energy aerospace engine

An engine and energy emission technology, applied in engine components, engine cooling, machine/engine, etc., can solve problems such as low efficiency, excessive volume, and small specific impulse of aerospace engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

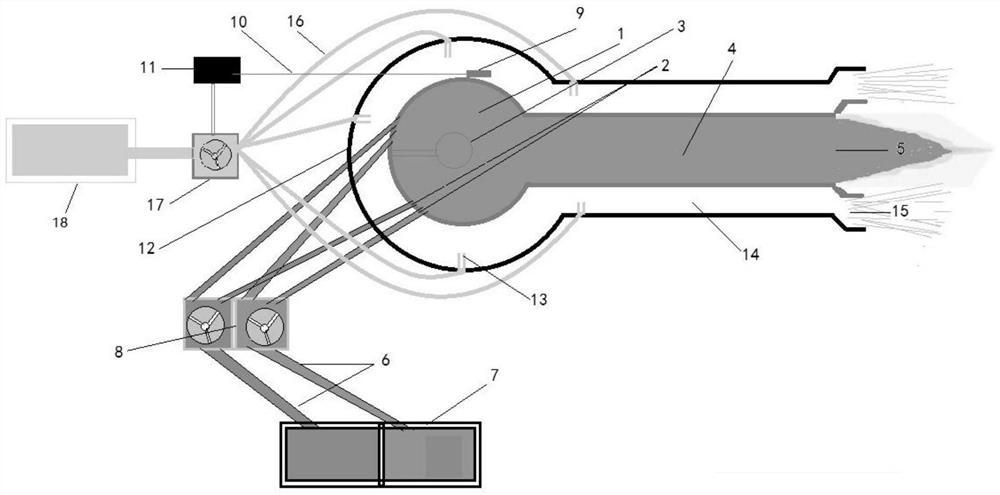

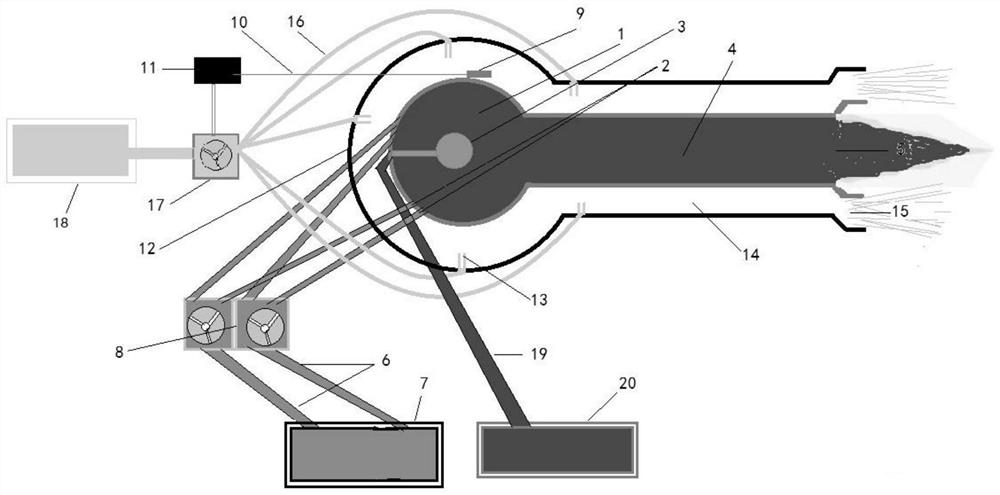

[0015] figure 1 It is a structural schematic diagram of the first embodiment of the present invention, showing that the energy chamber (combustion chamber) of the machine is injected with a mixture of oxygen and kerosene, and is ignited by the ignition device to perform work from the inner nozzle pipe and the inner nozzle, and the cooling cover sprays water to the gas. The energy chamber and the outer layer of the inner nozzle are cooled and converted into energy at the same time, and then the gas is ejected from the outer nozzle and the outer nozzle to do work; figure 2 same figure 1 , which shows that the energy chamber of the machine is injected with fluid working medium, and the energy emission device gives the working medium energy, which is sprayed out from the inner nozzle and the inner nozzle to do work, and at the same time, the cooling cover sprays water to cool the energy chamber and the outer layer of the inner nozzle. After the energy, the gas is ejected from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com