Efficient air compression device based on gas adsorption and desorption effect and method thereof

An adsorption-desorption and compression device technology, which is applied in the direction of liquid variable capacity machinery, machines/engines, mechanical equipment, etc., can solve the problems of small-scale compression heat, low-quality heat source, compression heat recovery, storage, and reuse, etc. problem, to achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A high-efficiency air compression device based on gas adsorption and desorption effect, including an adsorption and desorption device, an air bag, a gas conversion device, a compression device and a gas storage device.

[0047] The adsorption-desorption device is filled with a temperature-sensitive adsorption-desorption material, and gas working fluid is reversibly adsorbed on the temperature-sensitive adsorption-desorption material.

[0048] Temperature-sensitive adsorption and desorption materials refer to materials that can achieve reversible adsorption and desorption of gas working fluid at different temperatures; gas storage alloys such as MmNi can be selected 4.7 al 0.3 、MmNi 4.7 Fe 0.3 , La 0.85 Ce 0.15 Ni 5 Wait. Gas working medium can choose carbon dioxide, nitrogen, hydrogen and other gases.

[0049] The air bag communicates with the adsorption-desorption device and is used for storing gas working fluid; and the air bag is installed inside the gas conve...

Embodiment 2

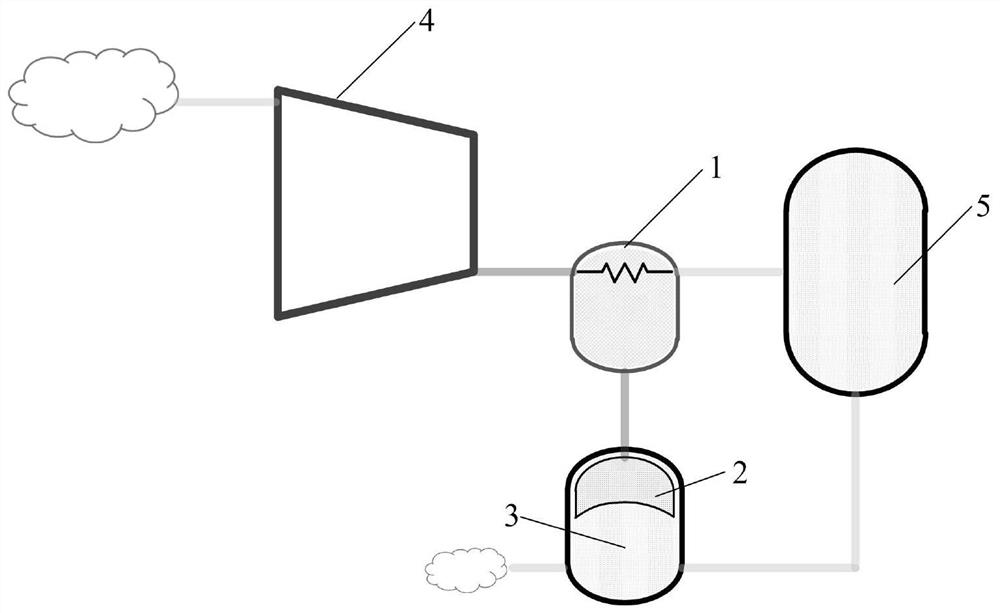

[0060] Such as figure 1 As shown, a high-efficiency air compression device based on gas adsorption and desorption effect includes an adsorption and desorption device 1 , an air bag 2 , a gas conversion device 3 , a compression device 4 and a gas storage device 5 .

[0061] The adsorption-desorption device 1 is filled with a temperature-sensitive adsorption-desorption material, and gas working fluid is reversibly adsorbed on the temperature-sensitive adsorption-desorption material.

[0062] Temperature-sensitive adsorption and desorption materials refer to materials that can achieve reversible adsorption and desorption of gas working fluid at different temperatures; gas storage alloys such as MmNi can be selected 4.7 Al 0.3 、MmNi 4.7 Fe 0.3 , La 0.85 Ce 0.15 Ni 5 Wait. Gas working medium can choose carbon dioxide, nitrogen, hydrogen and other gases.

[0063] The gas bag 2 communicates with the adsorption-desorption device 1 and is used for storing gas working fluid; and...

Embodiment 3

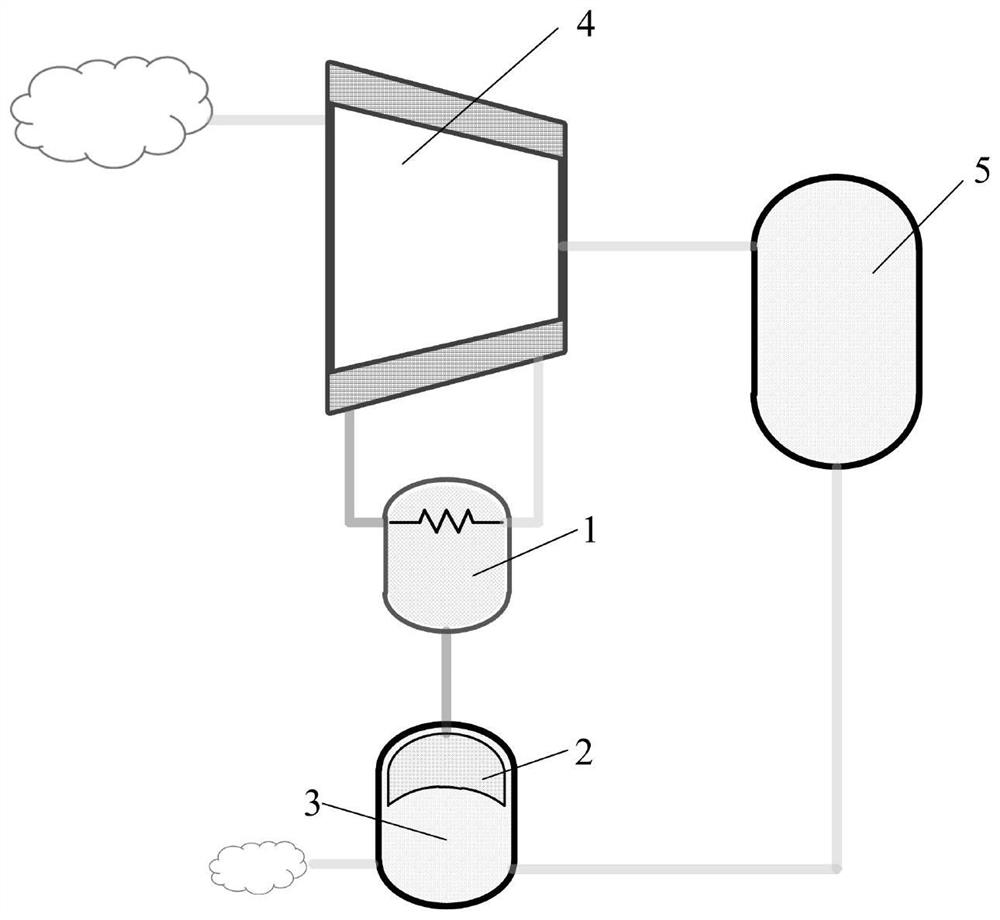

[0070] Such as figure 2 As shown, the compression device 4 is provided with a jacket outside; the heat transfer medium is passed into the jacket; The heat transfer medium can be gas medium or liquid medium. The compression device is also connected with an exhaust pipeline. All the other structures are with embodiment 1.

[0071] When in use, the heat generated by the compression device 4 is transferred to the adsorption-desorption device through the heat transfer medium circulating in the heat transfer pipeline, thereby heating the temperature-sensitive adsorption-desorption material and desorbing the gas working medium. The exhaust pipeline is used to deliver the compressed gas to the gas storage device 5 . All the other steps are the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap