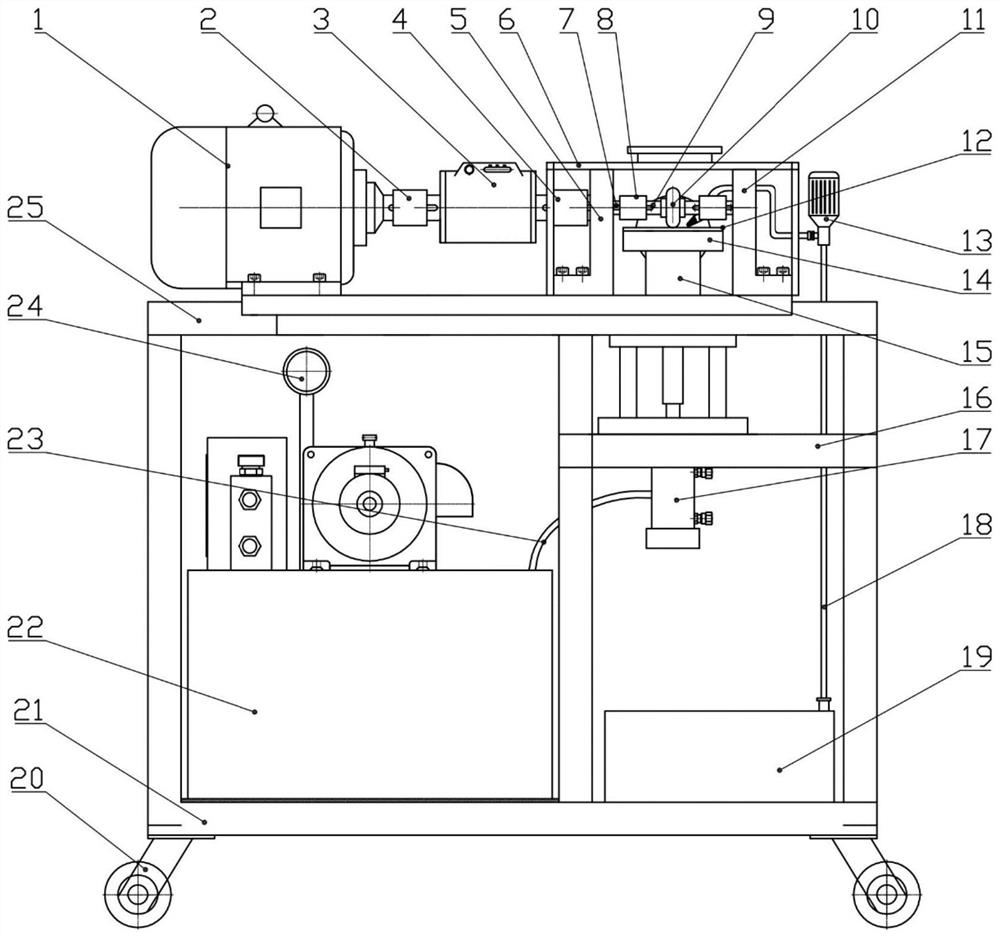

Testing machine for researching rubber ablation behavior of tire tread at moment of aircraft landing

A technology for tire treads and testing machines, which is used in chemical analysis using combustion, testing wear resistance, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

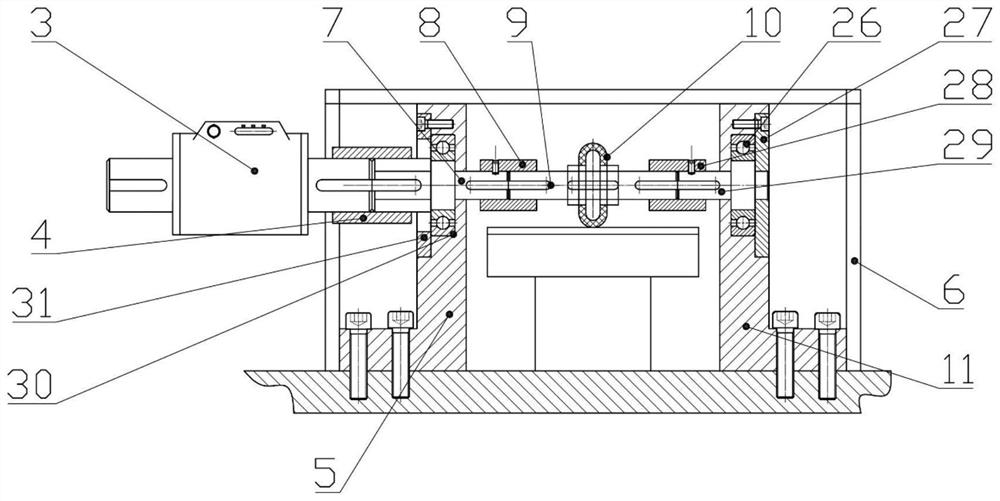

Method used

Image

Examples

Embodiment 1

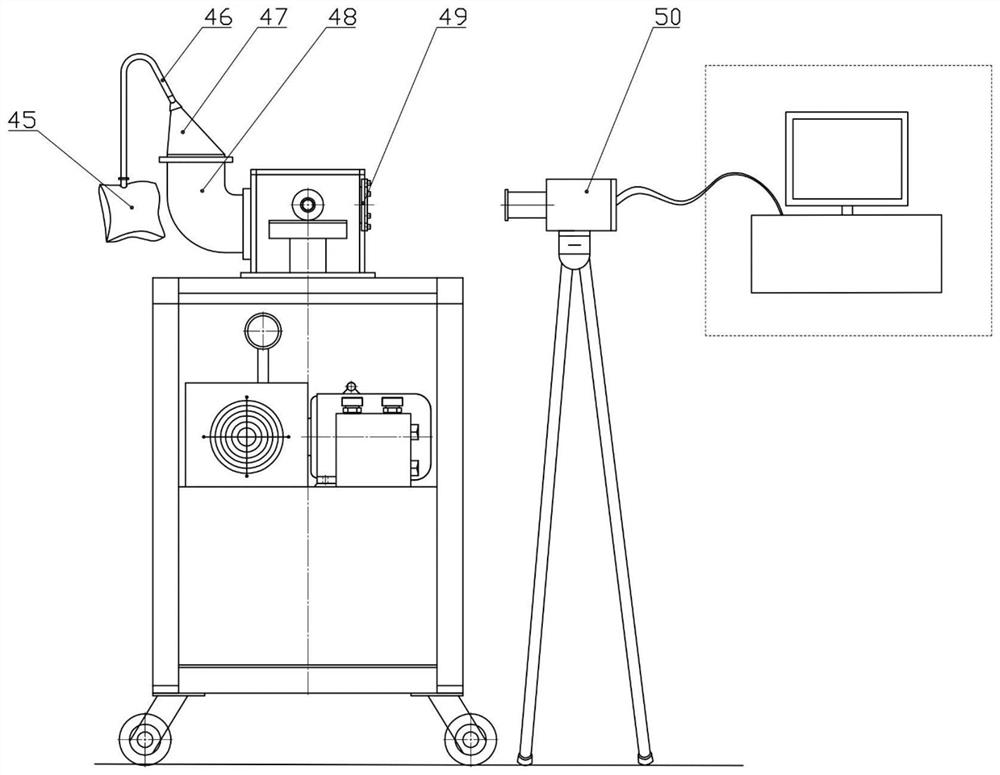

[0123] When adopting natural rubber to be 100 parts, carbon black to be 50 parts, halloysite to be 5 parts, when adopting rubber grinding wheel as test grinding wheel, adopt above-mentioned testing machine to test, infrared temperature detector 50 detects rubber grinding wheel friction ablation The maximum temperature is 212°C, see Figure 8 a;

[0124] When using styrene-butadiene rubber as 100 parts, carbon black as 60 parts, and titanium dioxide as 3 parts, when using rubber grinding wheel as the test grinding wheel, the maximum temperature of rubber grinding wheel friction and ablation detected by infrared temperature detector 50 is 218 ° C, see Figure 8 b;

[0125] When using butadiene rubber as 100 parts, carbon black as 70 parts, and carbon nanotubes as 2 parts, when using rubber grinding wheel as the test grinding wheel, the maximum temperature of rubber grinding wheel friction and ablation detected by infrared temperature detector 50 is 202 ℃, see Figure 8 c.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com