Intermittent process fault detection method and system considering two-dimensional dynamic characteristics

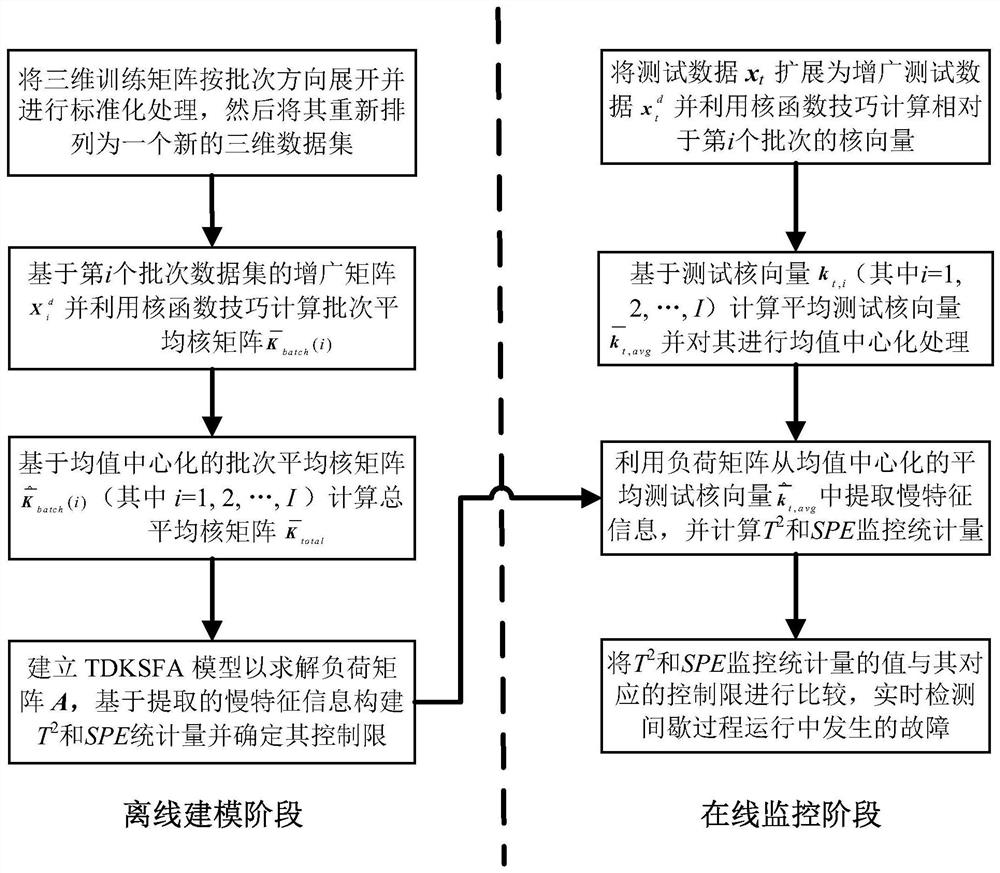

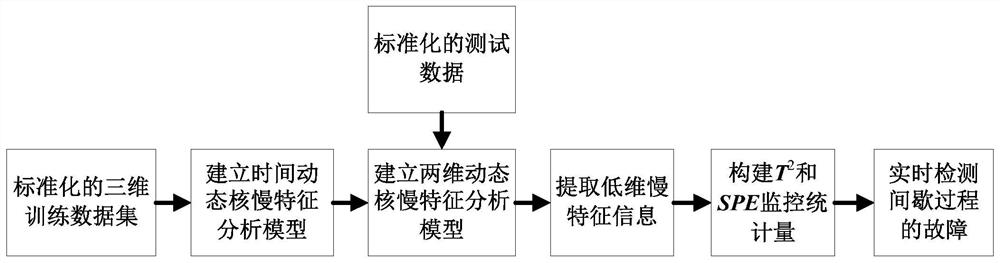

A dynamic characteristic and fault detection technology, applied in the direction of test/monitoring control system, general control system, control/regulation system, etc., can solve the problem of reducing fault detection performance, unable to eliminate batch dimension dynamic characteristics of intermittent process, and unable to handle intermittent process Problems such as strong nonlinear features can solve the dynamic characteristics, eliminate dynamic changes and random offsets, and improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

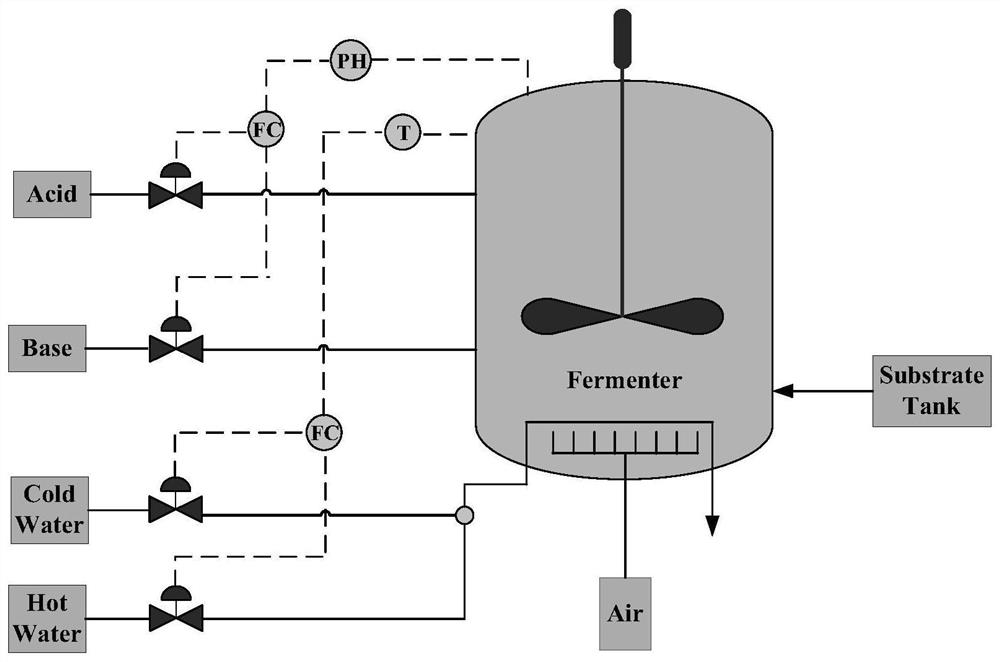

[0075]See the schematic diagram of the penicillin fermentation processimage 3 The fermentation process includes two operating stages: pre-cultivation stage and batch feeding stage. In the initial pre-culture stage, a large number of nutrients necessary for cells begin to be produced and penicillin cells appear in the exponential cell growth phase. In the fed-batch stage, in order to maintain high penicillin production, it is necessary to continuously supply glucose to the fermentation process to keep the biomass growth rate constant. In order to provide the best conditions for the production of penicillin, closed-loop control is adopted for the temperature and pH of the fermentation tank.

[0076]In the simulation experiment, Pensim V2.0 was used to generate simulation data of penicillin fermentation process. Select the 10 variables listed in Table 1 as monitoring variables, and add Gaussian noise in the variable sampling process. Collect 40 batches of data under normal working conditi...

Embodiment 2

[0184]This embodiment provides an intermittent process fault detection system considering two-dimensional dynamic characteristics, which includes:

[0185]The monitoring statistics calculation module uses the load matrix of the two-dimensional dynamic kernel slow feature analysis model to extract low-dimensional feature information of the test data, and calculates the monitoring statistics of the test data in the principal component space and the residual space; the test data is intermittent Different working condition data of the process;

[0186]Intermittent process fault judgment module, which is used to judge whether the intermittent process has a fault based on the comparison result of the monitoring statistics and the corresponding control limit;

[0187]Among them, the load matrix is constructed by solving the generalized eigenvectors corresponding to the optimization problem of the two-dimensional dynamic kernel slow characteristic analysis model; the construction process of the tw...

Embodiment 3

[0192]This embodiment provides a computer-readable storage medium on which a computer program is stored. When the program is executed by a processor, the steps in the intermittent process fault detection method considering the two-dimensional dynamic characteristics described in the first embodiment are implemented. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com