Weaving production line quality and fault detection statistical system

A fault detection and statistical system technology, applied in the field of textile production, can solve the problems of the difficulty of judging and analyzing textile quality accidents, the difficulty of troubleshooting, the difficulty of calculation and analysis, etc., to increase portability, fast query speed, and avoid duplication Sexual Setting Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Attached below Figure 1-4 Specific examples of the present invention are described.

[0031] The following examples facilitate a better understanding of the present invention, but do not limit the present invention. The following embodiments are only some of the embodiments of the present invention, but not all of them.

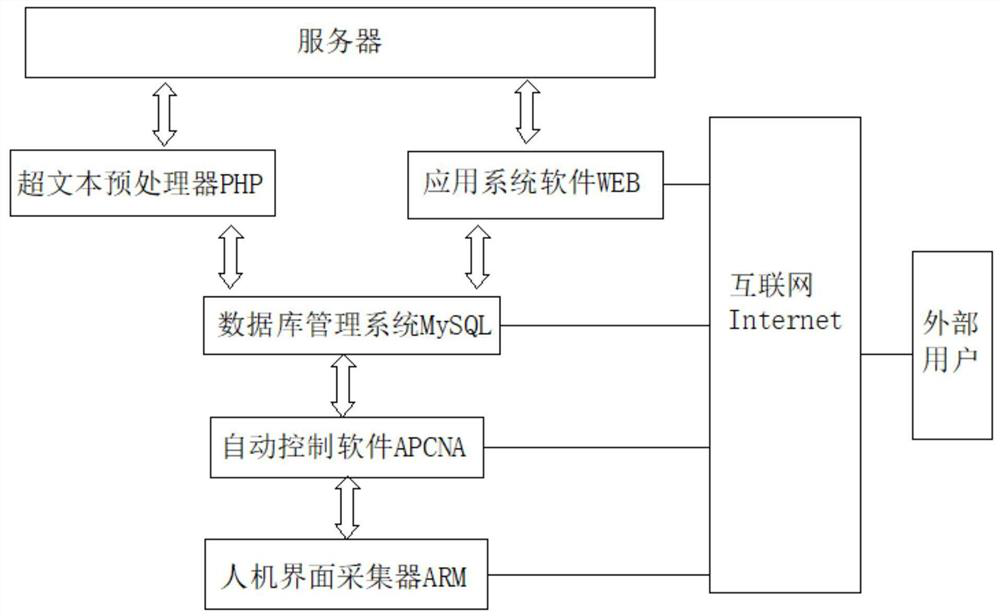

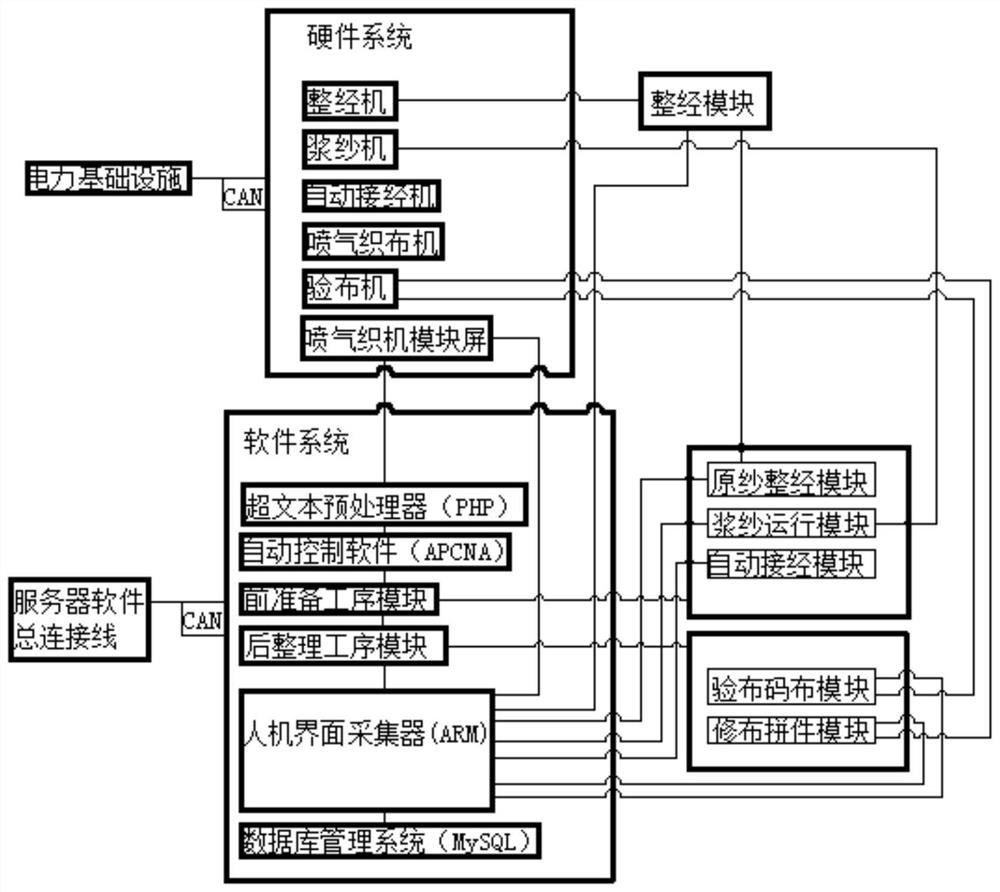

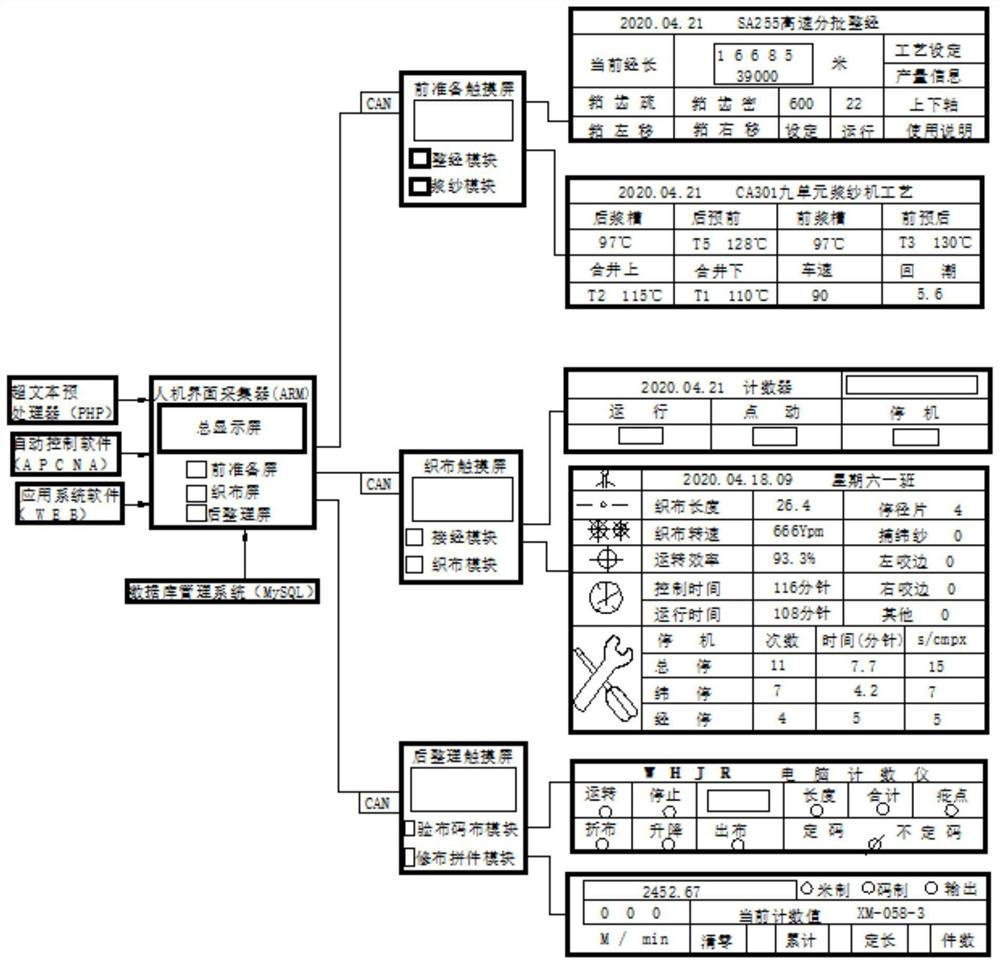

[0032] A weaving production line quality and fault detection statistical system, (such as figure 1Shown) includes a hardware system and a software system. The main improvement of the present invention lies in: the first establishment of a network monitoring system for a vertical loom production line, realizing the data consistency monitoring of textile production equipment, and avoiding the repetitive design of a large amount of data while ensuring the accuracy of shift data. fixed, thereby increasing production efficiency. Wherein, the hardware system includes a warping machine, a sizing machine, an automatic warp-tying machine, an air-jet loom, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com