Drum-type sheet cut tobacco dryer in tobacco primary processing

A thin plate drying machine, drum-type technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of low production capacity, low dehydration rate, low filling value, etc., to achieve increased filling value, uniform moisture content, and reduce irritation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

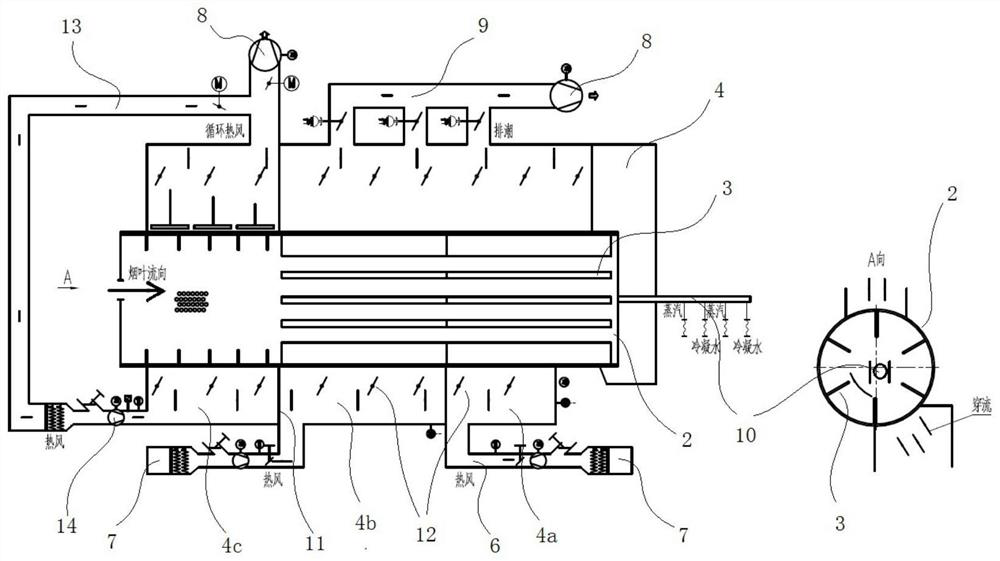

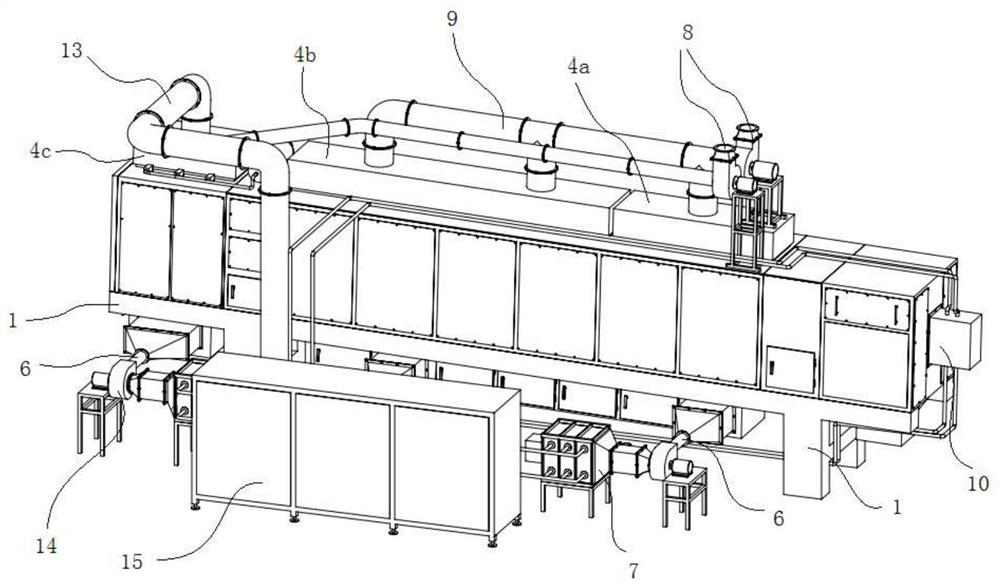

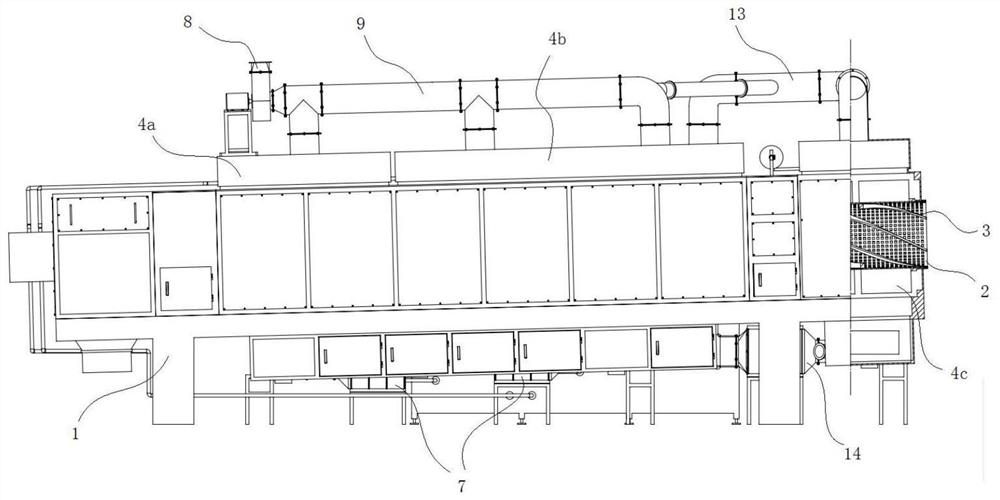

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, specific implementations thereof will be described in detail below in conjunction with the accompanying drawings.

[0031]A drum-type sheet drying machine for shredded tobacco as shown in the accompanying drawings, including a frame assembly 1, a shred drying device arranged on the frame assembly 1, and a pipeline arranged on one side of the frame assembly 1 The control cabinet 15, the silk drying device is electrically connected to the control device, and the silk drying device includes a silk drying cylinder 2, a wind cover 4, a silk drying cylinder rotating mechanism 5, a hot air pipe 6, a hot air generator 7 and a moisture discharge pipe 8, wherein , the drying cylinder 2 is a straight cylinder structure with two ends open, one end is the feeding end, and the other end is the discharging end, and a drying cylinder rotating mechanism 5 is arranged coaxial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com