Longitudinal shearing and slitting technology for precision stainless steel cold-rolled thin strip

A technology of slitting and slitting stainless steel, which is applied in the direction of shearing devices, metal rolling, shearing equipment, etc., can solve the problems of waste of raw materials, sickle bending, and affecting the service life of electronic products, so as to improve the yield of finished products and increase the size The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

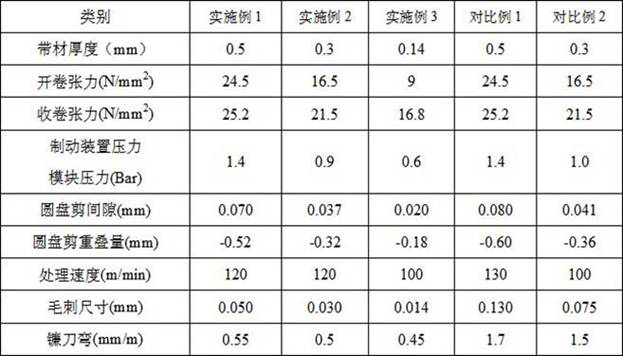

[0013] In order to further understand the content of the invention and the characteristics of the technical process of the present invention, the following examples are given for detailed description. A specific implementation of the slitting and slitting process for precision stainless steel cold-rolled thin strips is as follows:

[0014]

[0015] Taking Examples 1 and 2 as reference, comparative examples 1 and 2 were prepared respectively:

[0016] According to the technical solution provided by the present invention, in Example 1 and Example 2, the burr sizes after slitting and slitting of precision stainless steel cold-rolled thin strips are respectively 0.050mm and 0.030mm, and the camber dimensions are respectively 0.55mm / m and 0.5mm. mm / m; According to the technical parameters listed in Comparative Example 1 and Comparative Example 2, the burr sizes after slitting and slitting of precision stainless steel cold-rolled thin strips are 0.130mm and 0.075mm, and the camber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com