A three-color push and turn automatic forming mechanism

An automatic forming and movable insert technology, applied in the field of injection molds, can solve the problems of long production cycle of parts and unfavorable mass production of parts, and achieve the effect of shortening production cycle, improving long production cycle, ingenious design and practical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

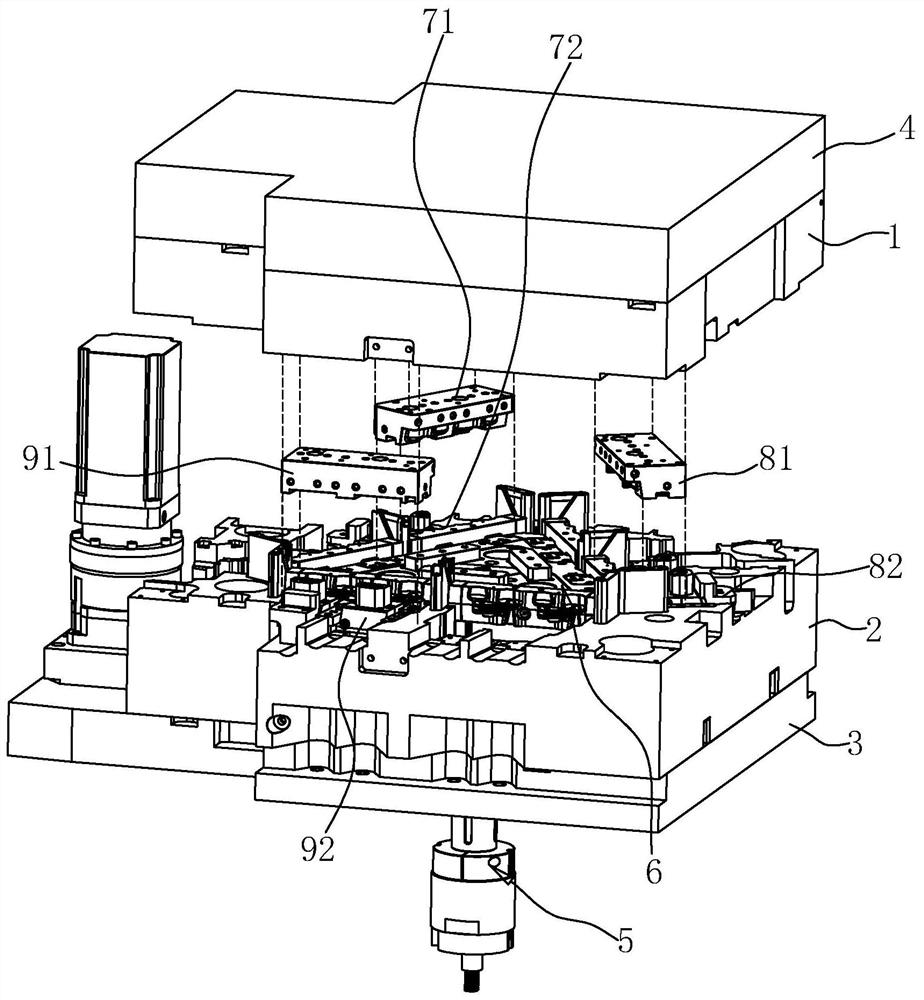

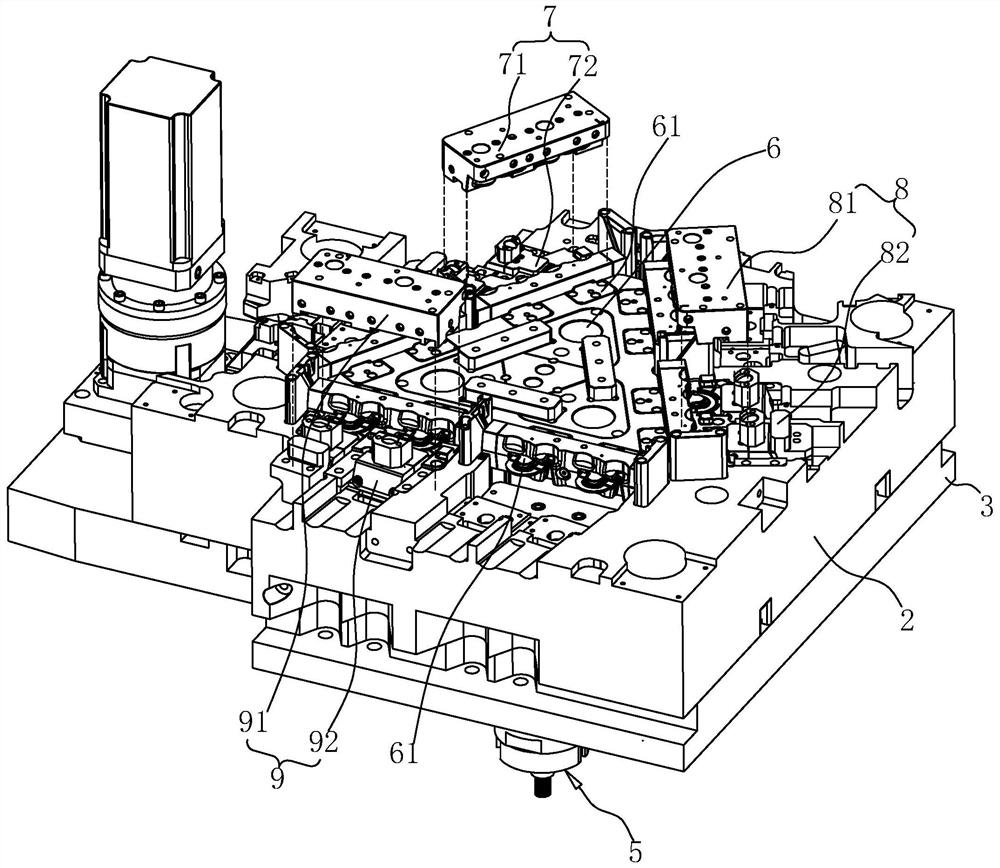

[0044] The following is attached Figure 1-12 The application is described in further detail.

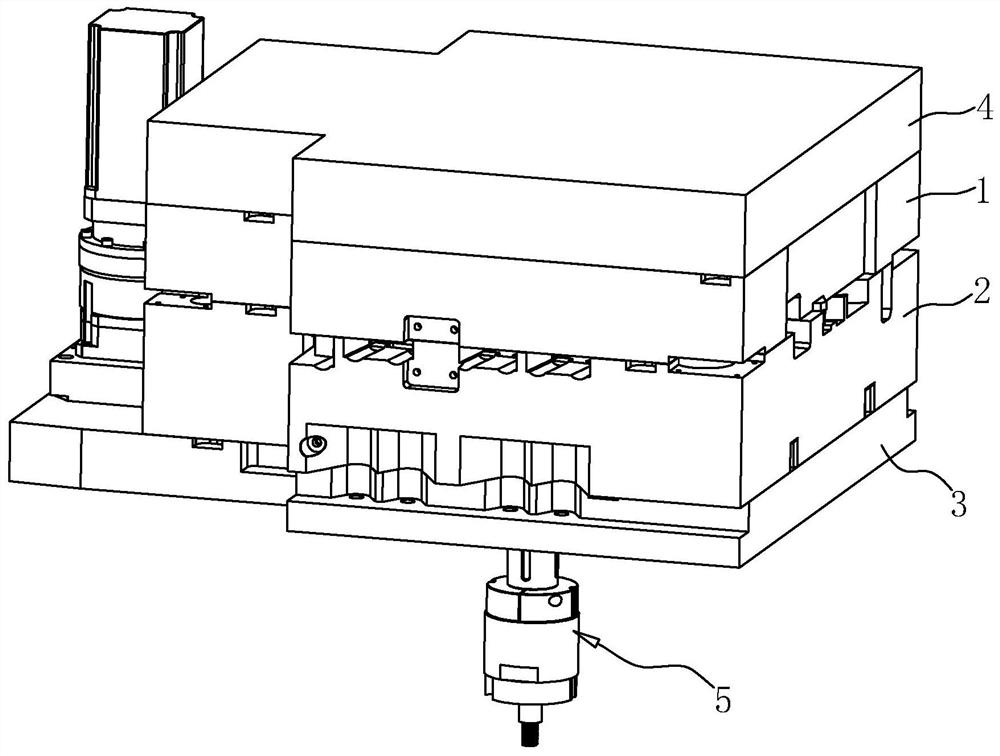

[0045] The embodiment of the present application discloses a three-color push and turn automatic forming mechanism. refer to figure 1 and figure 2 , the mechanism includes A board 1 , B board 2 , top core rotating assembly 5 and rotating insert 6 .

[0046] In this embodiment, the mold mainly includes parts such as top plate 4, A plate 1, B plate 2 and bottom plate 3. The plates 2 are fixed to each other, the bottom plate 3 is used to fix the injection molding machine, and the A plate 1 and the B plate 2 are opposite to each other. The injection molding machine drives the top plate 4 and the bottom plate 3 to approach or move away from each other, so that the A plate 1 and the B plate 2 are close to or far away from each other. When the A plate 1 and the B plate 2 are close to each other until they touch each other, the mold is now closed. Mold; when the A plate 1 and B plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com