Feeding device of injection molding machine

A technology of a feeding device and an injection molding machine, which is applied in the field of feeding devices, can solve the problems of waste of injection molding raw materials, pollution of injection molding raw materials, waste of raw materials, etc., and achieve the effects of reducing costs, reducing pollution, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

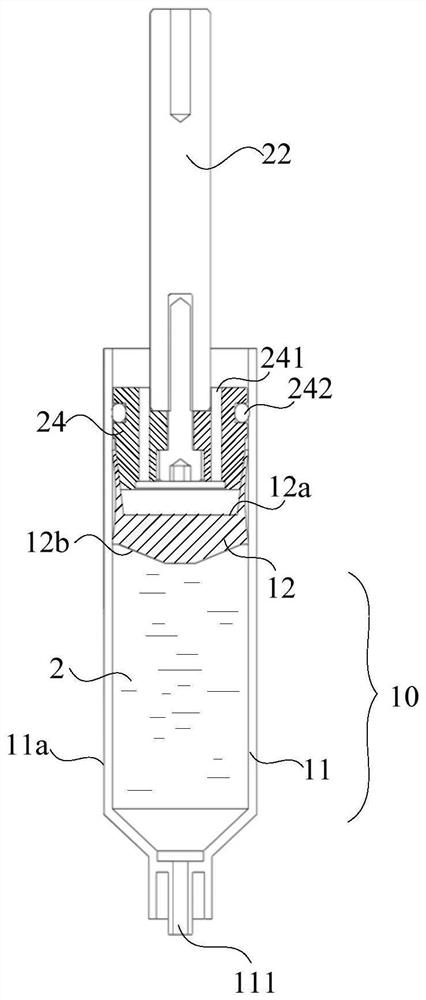

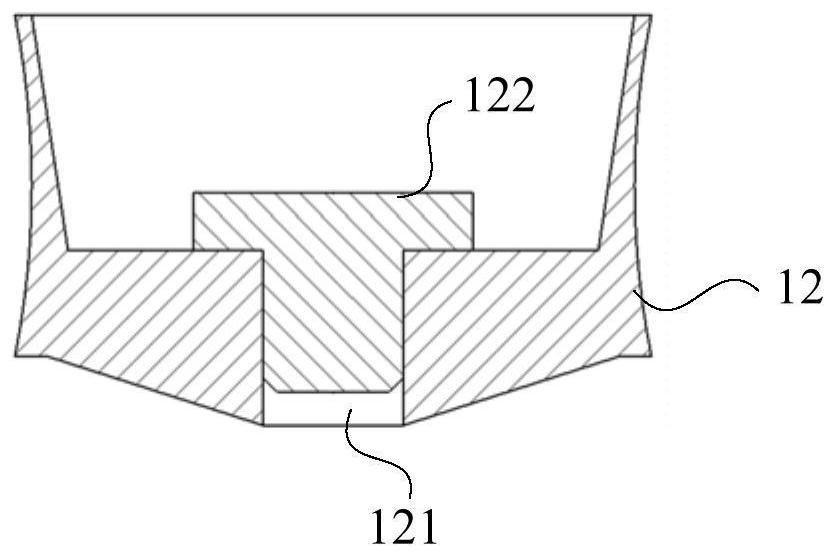

[0029] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In the following description, the same reference numerals are given to the same components, and repeated descriptions are omitted. In addition, the drawings are only schematic diagrams, and the ratio of dimensions between components, the shape of components, and the like may be different from the actual ones.

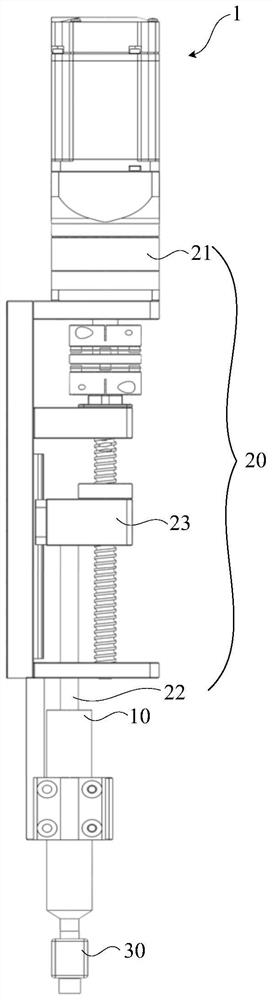

[0030] This embodiment relates to a feeding device for an injection molding machine. In this embodiment, the feeding device of the injection molding machine can also be referred to as the feeding device for short. The feeding device mainly provides injection molding materials for the mold of the injection molding machine. The feeding device of the injection molding machine involved in this embodiment is particularly suitable for, for example, Injection molding of biocompatible polymer materials. A detailed description will be given below in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com