Nondestructive cutting and cracking device for photovoltaic cell

A technology of photovoltaic cells and cells, which is applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of poor breaking accuracy and failure to meet the production requirements of cells, so as to improve the processing quality and increase the splitting operation rate , The effect of ensuring the accuracy of the lobes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

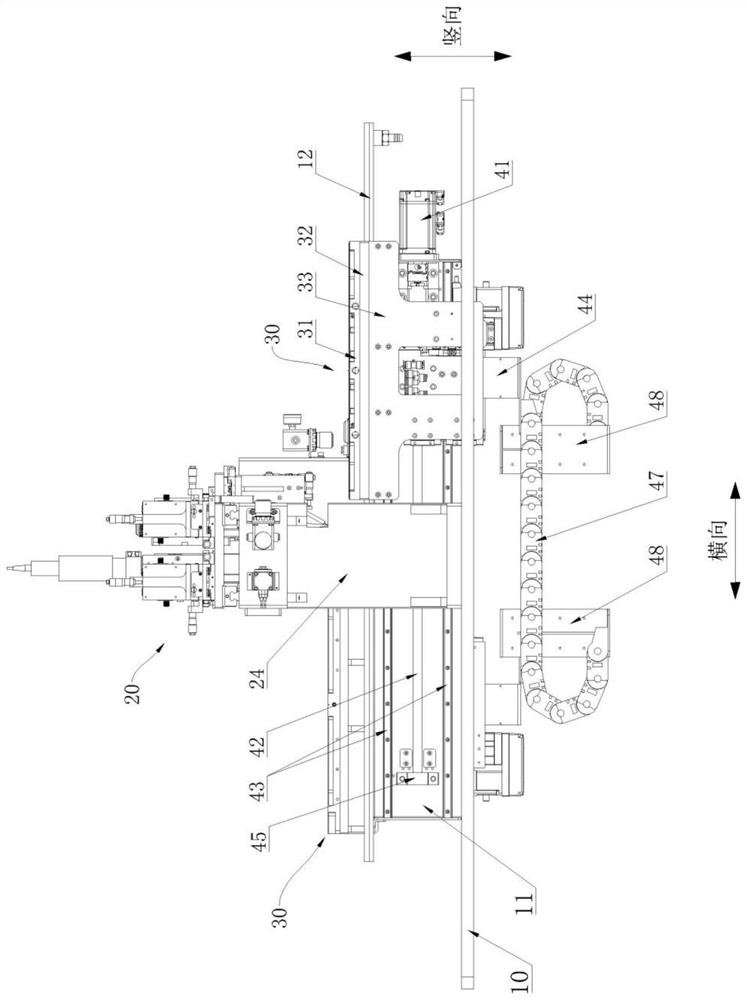

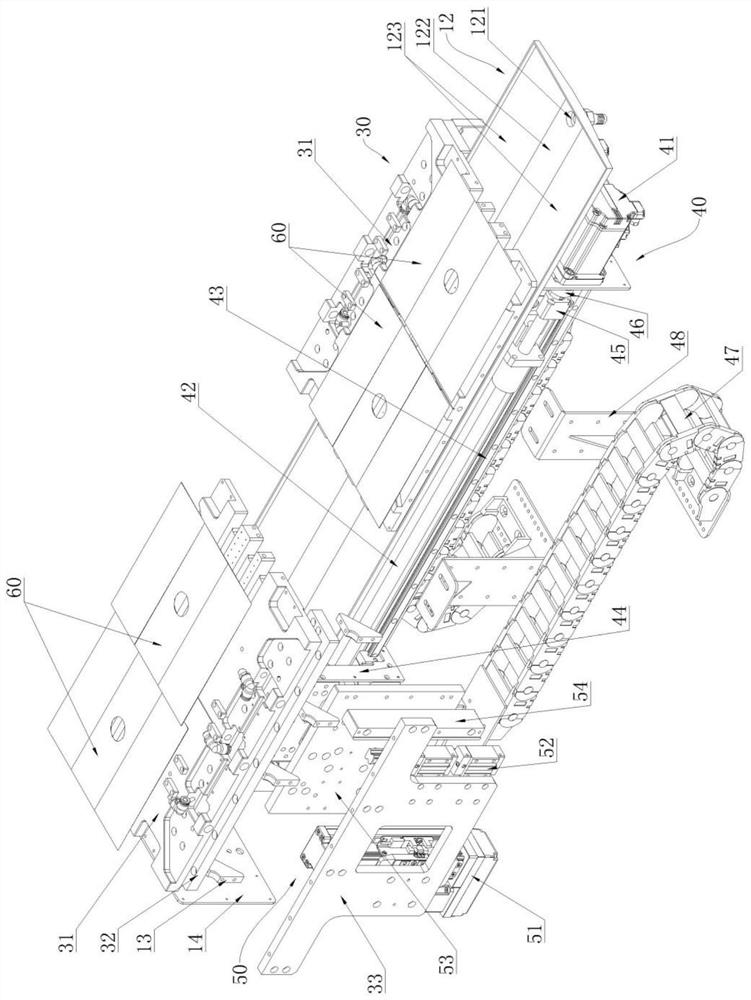

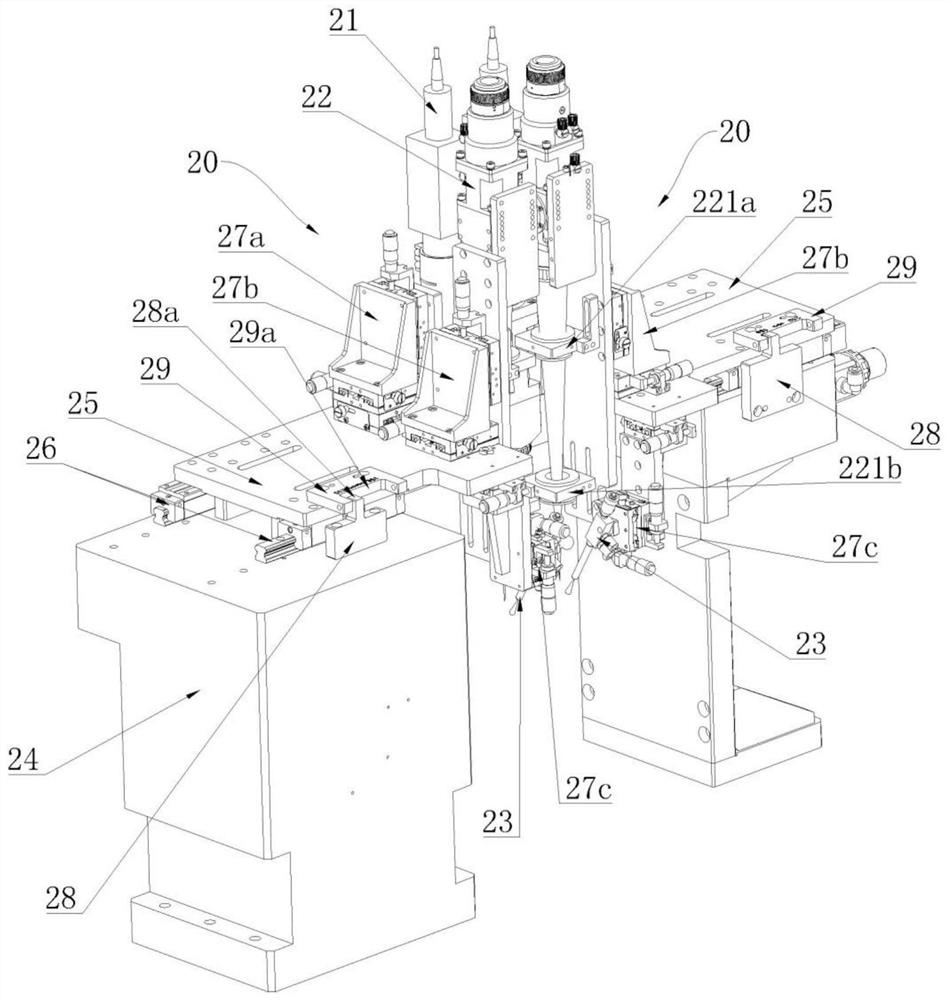

[0021] See Figure 1 to Figure 4 , The present invention is a non-destructive cutting and splitting device for photovoltaic cells, which includes a device platform plate 10, a splitting mechanism 20 and two sets of carrier platform mechanisms 30. The carrier platform mechanism 30 includes a carrier platform 31 for adsorbing and positioning cells. At least two precisely positioned battery sheets 60 are adsorbed and positioned along the cutting direction (that is, the horizontal direction in this embodiment). The device platform board 10 is provided with a horizontal support 11 extending linearly in the horizontal direction. The longitudinal sides of the horizontal support 11 A set of lateral translation mechanisms 40 are respectively installed on the two sets of lateral translation mechanisms 40, and a set of platform mechanisms 30 are respectively installed on the two sets of lateral translation mechanisms 40 through a set of vertical lifting mechanisms 50. The mechanism 20 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com