Small-aperture shallow hole filling method for model blasting experiment

A small-diameter, shallow-hole technology, applied in the field of blasting tests, can solve problems such as the difficulty of filling small-diameter blastholes, the long time for packing materials to dry quickly, and the lack of model test data, so as to improve blasting effects and reduce explosions. risk, and the effect of improving the packing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

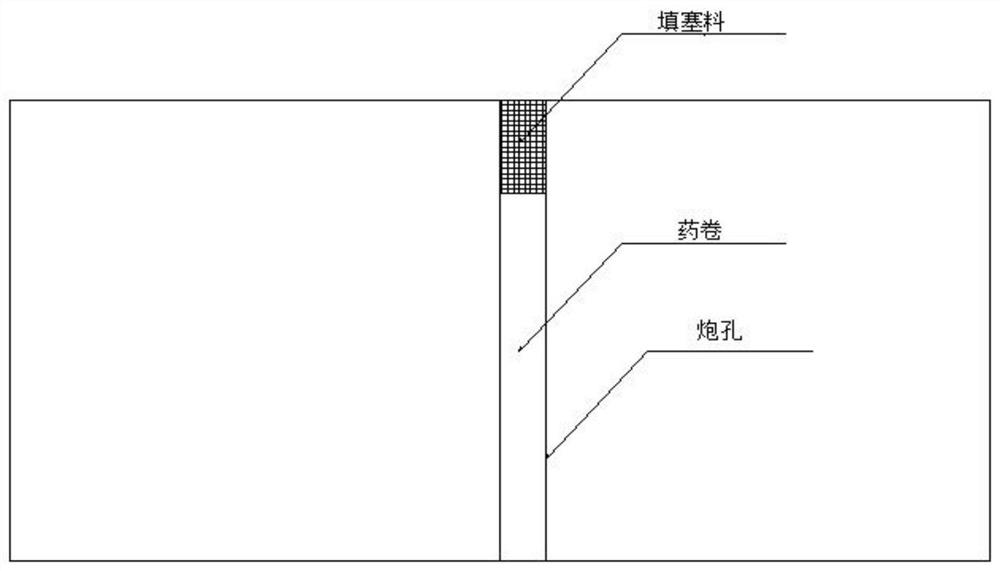

[0020] Embodiment 1: as figure 1 As shown, a model blasting experiment small hole shallow hole filling method, the specific steps are as follows:

[0021] (1) Mix the fast-sticking powder, water and liquid binder evenly to obtain the packing slurry; the mass ratio of the fast-sticking powder, water and liquid binder in the packing slurry is 10:4:1; this model experiment The selected liquid adhesive is commercially available glue, and the type of commercially available glue is sBS resin glue;

[0022] (2) Clean up the small-diameter blastholes for model testing, place the explosives at the bottom of the small-diameter blastholes according to the design requirements, add part of the filling slurry into the small-aperture blastholes, then add brown silk and stir, and then repeatedly add the filling slurry material and brown silk, after the filling is completed, wait for the filling slurry to solidify to complete the filling of the small-aperture shallow hole in the model blastin...

Embodiment 2

[0025] Embodiment 2: as figure 1 As shown, a model blasting experiment small hole shallow hole filling method, the specific steps are as follows:

[0026] (1) Mix the fast-sticking powder, water and liquid binder evenly to obtain the packing slurry; the mass ratio of the fast-sticking powder, water and liquid binder in the packing slurry is 10:6:2; this model experiment The selected liquid adhesive is commercially available glue, and the type of commercially available glue is sBS resin glue;

[0027] (2) Clean up the small-diameter blastholes for model testing, place the explosives at the bottom of the small-diameter blastholes according to the design requirements, add part of the filling slurry into the small-aperture blastholes, then add brown silk and stir, and then repeatedly add the filling slurry material and brown silk, after the filling is completed, wait for the filling slurry to solidify to complete the filling of the small-aperture shallow hole in the model blastin...

Embodiment 3

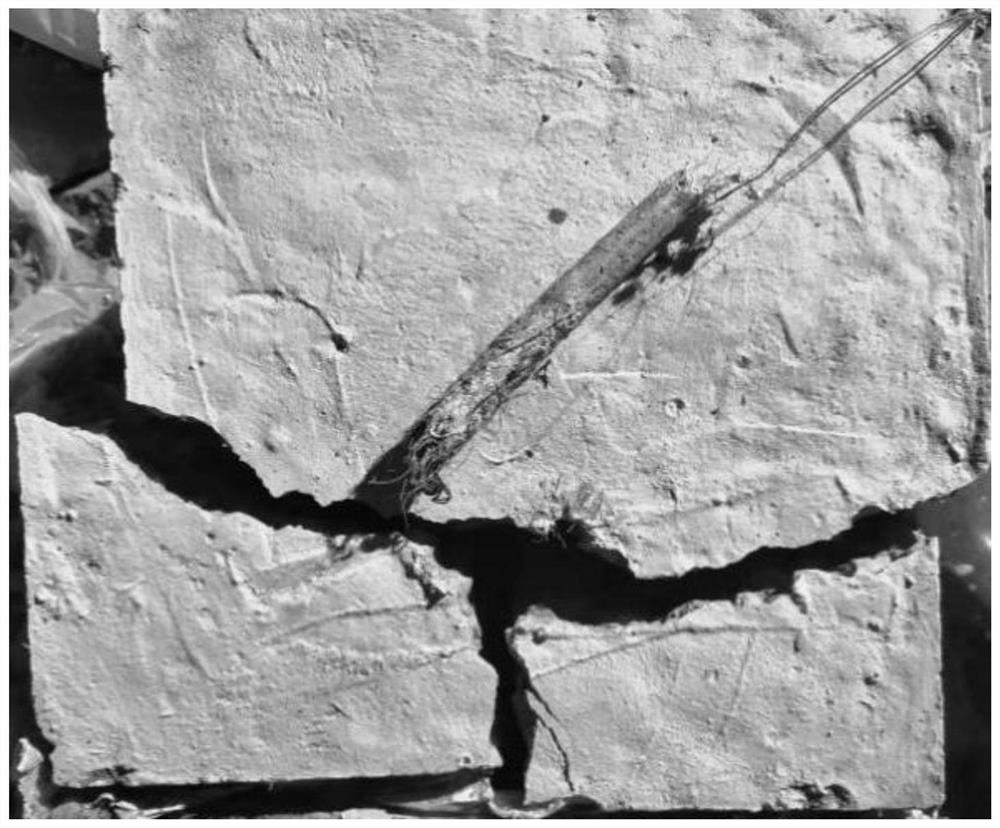

[0030] Embodiment 3: as figure 1 As shown, through the model poured in the Dahongshan Copper Mine, a model similar to the principle but reduced in size is made for experimental research. According to the experimental results converted to the principle, the experimental error can be reduced and the accuracy of the model experimental data can be improved; a The filling method of small aperture and shallow hole in model blasting experiment, the specific steps are as follows:

[0031] (1) Mix the fast-sticking powder, water and liquid binder evenly to obtain the packing slurry; the mass ratio of the fast-sticking powder, water and liquid binder in the packing slurry is 10:6:1; this model experiment chooses The liquid adhesive is commercially available glue, and the type of commercially available glue is sBS resin glue;

[0032] (2) Clean up the small-diameter blastholes for model testing, place the explosives at the bottom of the small-diameter blastholes according to the design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com