Atomizer cleaning tank with automatic cleaning function

A technology of atomizer and cleaning tank, applied in the direction of spray device, etc., can solve the problem of inconvenient cleaning of the atomizing head, and achieve the effects of convenient automatic cleaning, labor reduction, and low cleaning cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

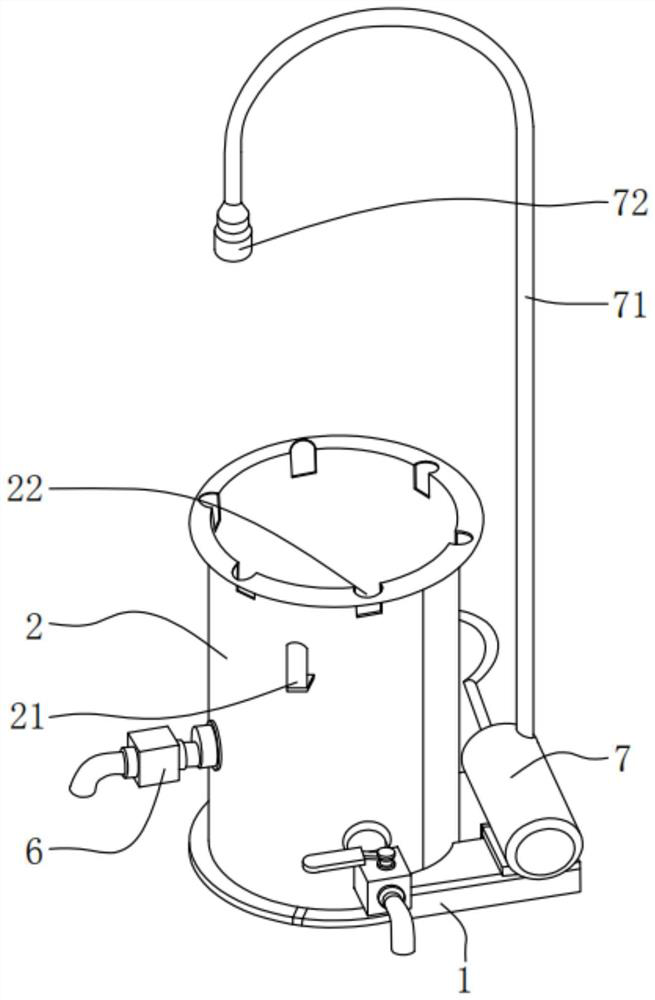

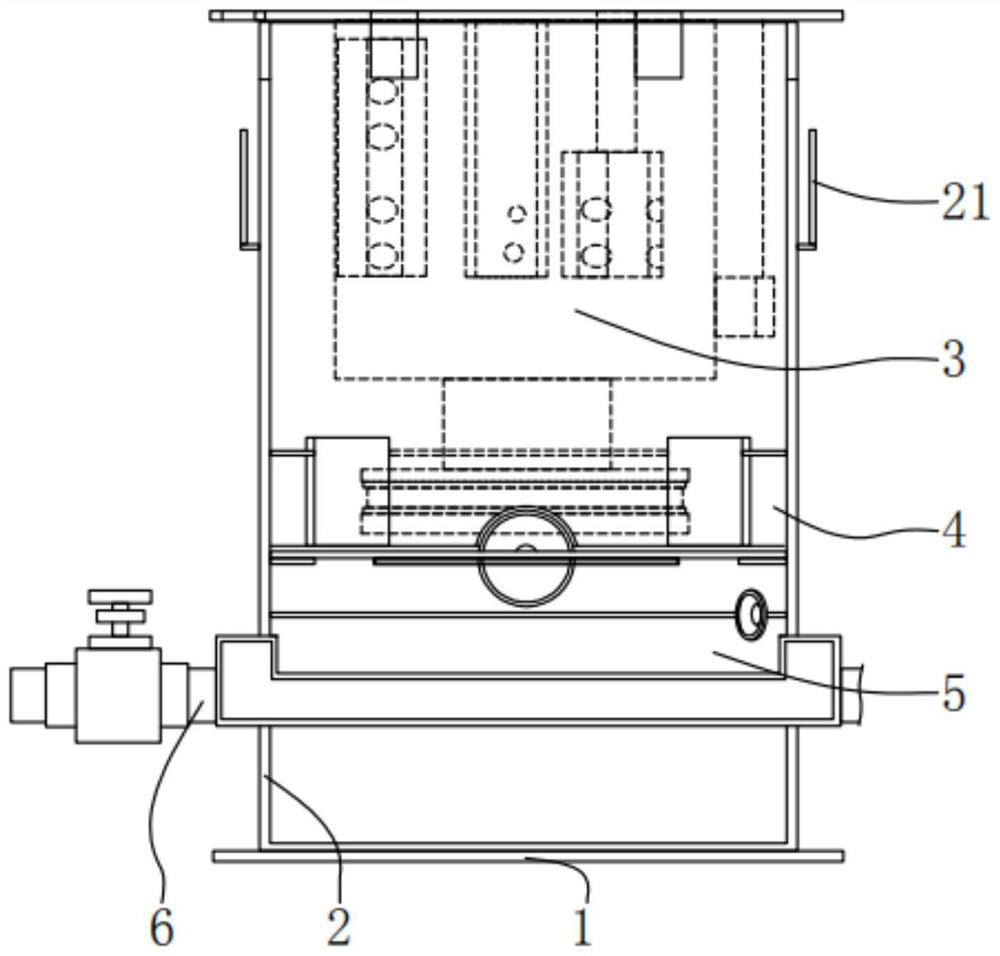

[0031] see Figure 1-2 , the embodiment of the present invention provides a technical solution: an atomizer cleaning tank with automatic cleaning function includes a base 1, a tank body 2 is connected to the top of the base 1, and the outer surface of the tank body 2 is provided with Cable support 21, the top of the tank body 2 is provided with an atomizer positioning port 22, the inside of the tank body 2 is respectively provided with a cleaning cavity 3 and an underflow cavity 5, the cleaning cavity 3 and An overflow port 4 is arranged between the lower overflow chambers 5, the input end of the overflow port 4 communicates with the inside of the cleaning chamber 3, and the output end of the overflow port 4 communicates with the interior of the cleaning chamber 3. The interior of the underflow cavity 5 is connected to each other, the output end of the underflow cavity 5 is provided with a manual acid discharge port 6, and the top of the base 1 is fixedly connected with an aci...

no. 2 example

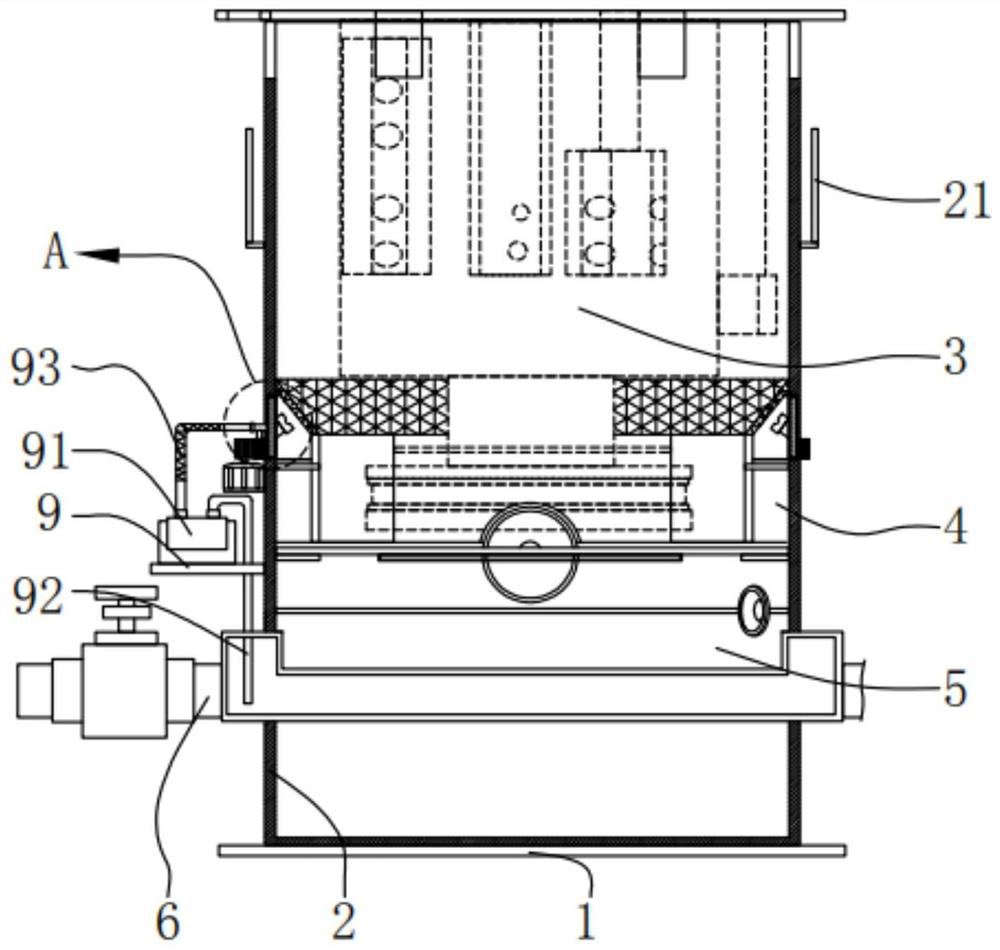

[0046] see image 3 and Figure 4 , based on the atomizer cleaning tank with automatic cleaning function provided in the first embodiment of the present application, the second embodiment of the present application proposes another atomizer cleaning tank with automatic cleaning function. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment. Specifically, the difference between the atomizer cleaning tank with automatic cleaning function provided in the second embodiment of the present application is that the atomizer cleaning tank with automatic cleaning function also includes a shielding screen 8, the The shielding screen 8 is fixed on the top of the overflow port 4, and the shielding screen 8 is arranged obliquely with an inclination angle of 45°. The outer surface of the tank body 2 is provided with a linkage sliding hole 23, and the link...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com