Ultrasonic cleaning device

A cleaning device and ultrasonic technology, applied in the directions of drying gas arrangement, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of unfiltered, dirty cleaning liquid, unable to achieve continuous and efficient cleaning of workpieces, etc. Easy to clean and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

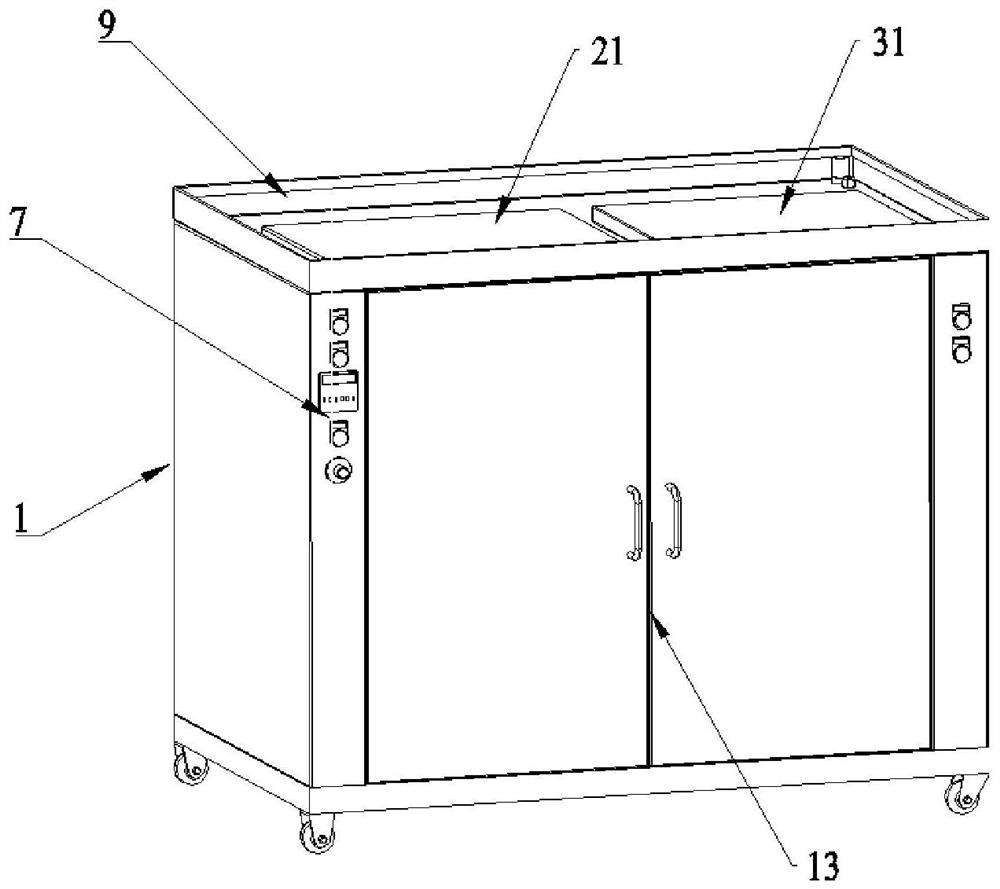

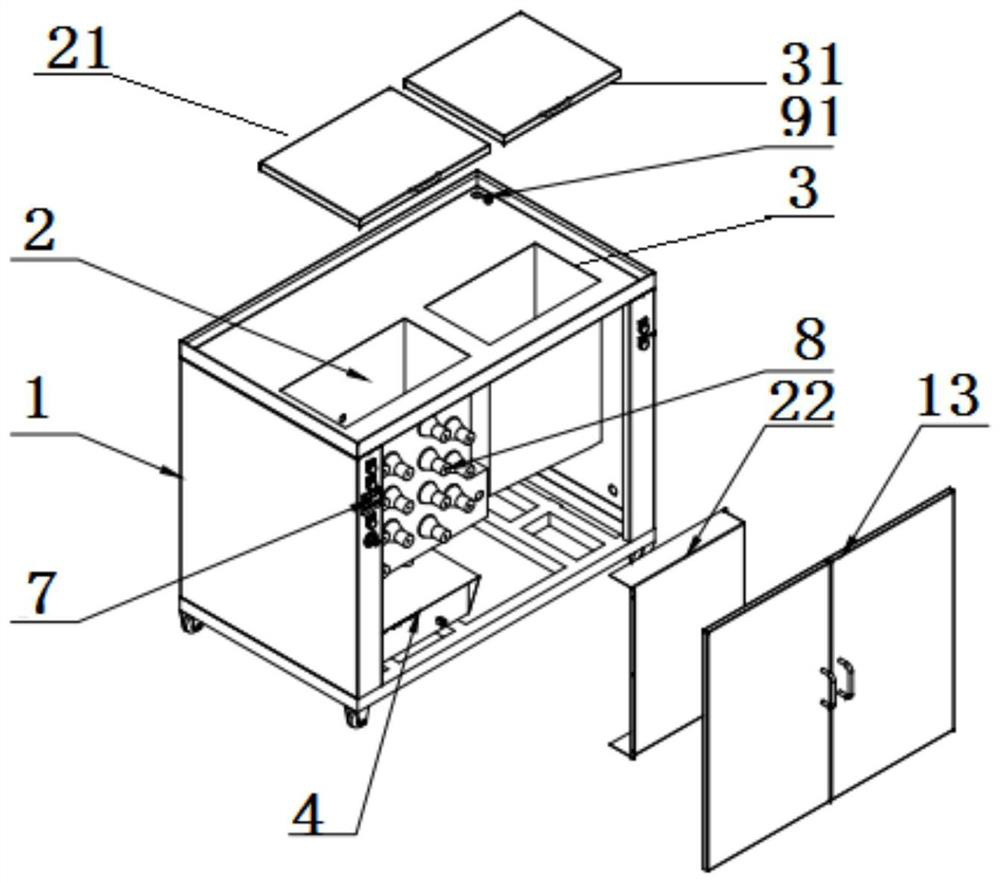

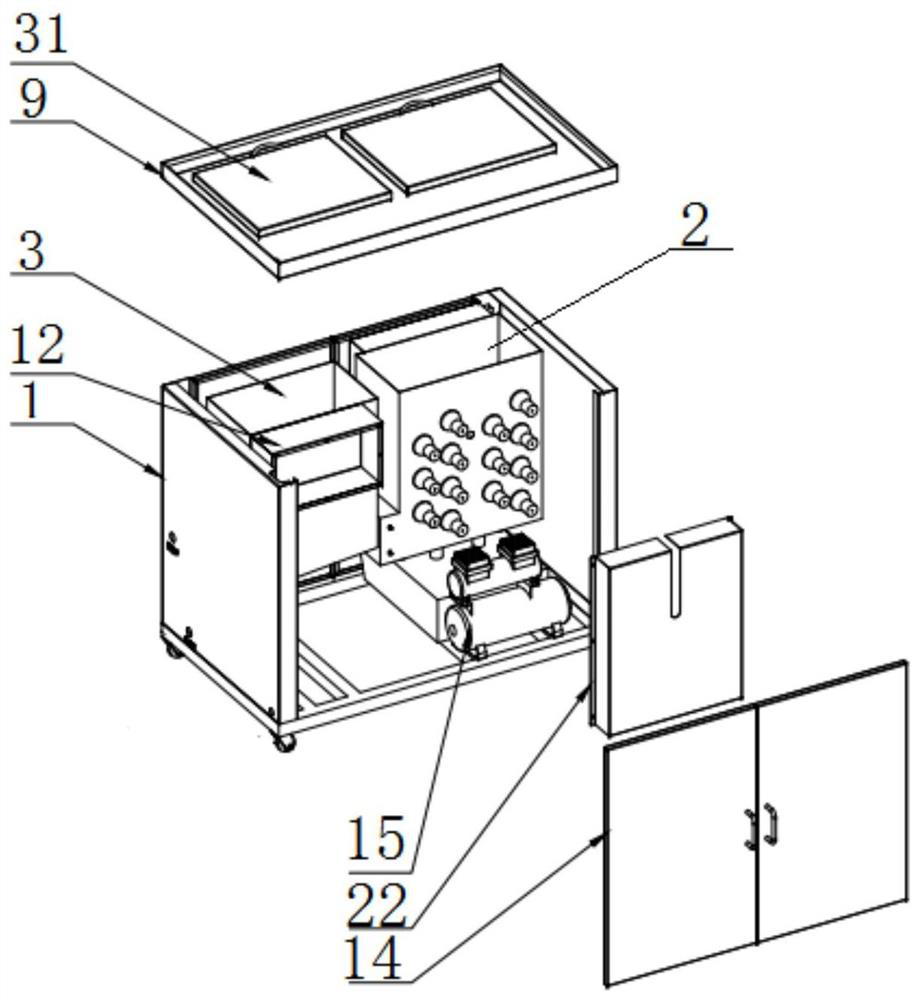

[0025] For the convenience of those skilled in the art to understand, below in conjunction with embodiment and appended Figure 1-8 To further illustrate the present invention, the content mentioned in the embodiment is not to limit the present invention.

[0026] See Figure 1-8 , an ultrasonic cleaning device, comprising a machine base 1, a cleaning tank 2, a drying tank 3, an ultrasonic generator 4, a water circulation system 5, an automatic heating mechanism 6, a numerical control component 7, an air compressor 15 and several ultrasonic vibrators 8, The water circulation system 5 includes a water inlet pipe 51, a circulating water pump 52, a first water outlet pipe 54, a filter 55, a second water outlet pipe 56, a purifier 57, a metal bellows 58 and a third water outlet pipe 59 connected in sequence; The cleaning tank 2 is set in the base 1, the drying tank 3 is set in the base 1 and is located on one side of the cleaning tank 2, and the ultrasonic generator 4 is set in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com