Curved screen protective film and manufacturing method thereof

A technology of curved screen and protective film, applied in the direction of pressure-sensitive film/sheet, film/sheet-like adhesive, adhesive, etc., can solve the problems of poor flatness, peeling off of protective film, poor bending performance, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

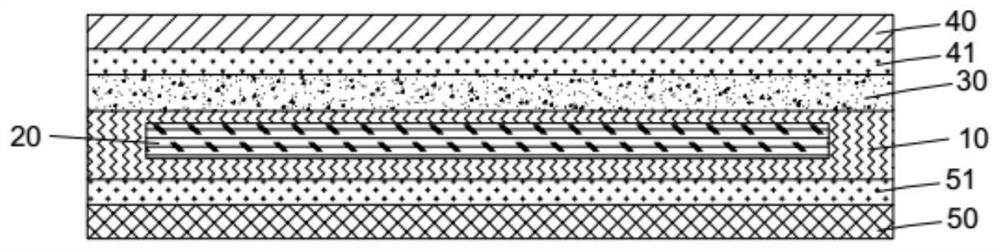

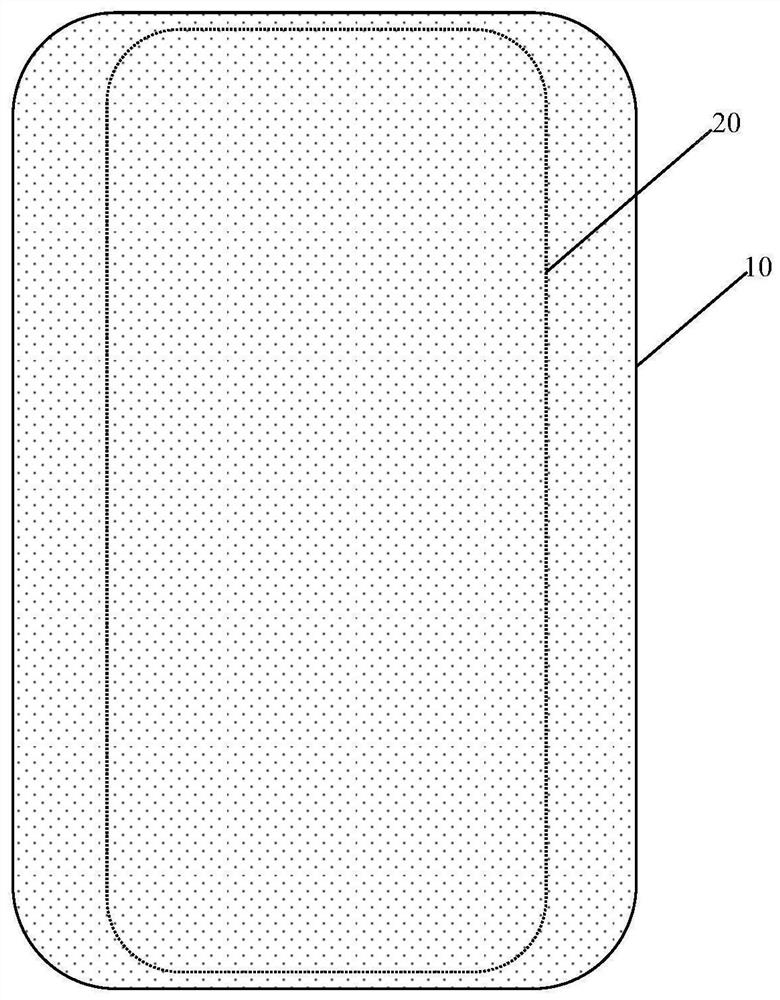

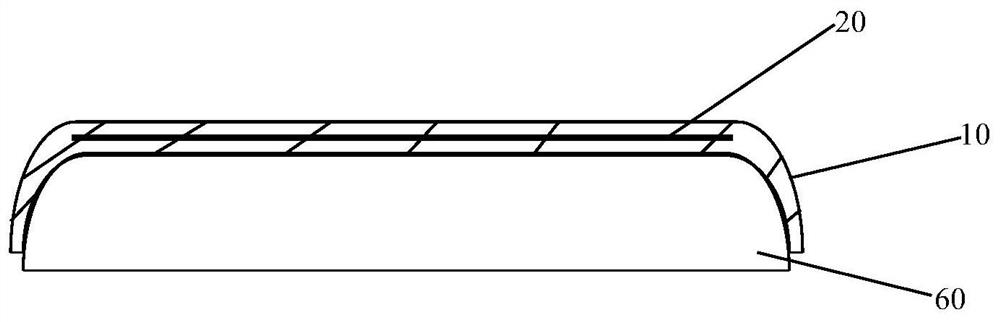

[0024] A curved screen protective film, which is used to be attached to the curved screen to protect the curved screen. The curved screen is a display screen with a curved edge.

[0025] to combine figure 1 , figure 2 , curved screen protective film, with a TPU film 10, the TPU film is provided with a reinforcement layer 20, the reinforcement layer is located in the center of the TPU film, the reinforcement layer is equal to the main screen of the curved screen, and the two sides of the TPU film can be attached to both sides of the curved screen on the surface. Among them, the main screen of the curved screen, that is, the flat part of the curved screen, occupies most of the area of the curved screen.

[0026] As an option, the reinforcing layer 20 is a PC film or a PMMA film.

[0027] The reinforcement layer 20 is coated or heat-pressed on the TPU film 10 . The reinforcement layer 20 is coated on the TPU film 10, and the reinforcement layer is located in the TPU film 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com