Rapid analysis method for rigidity of rubber-metal composite suspension

A technology of rubber-metal composite and suspension stiffness, which is applied in instrumentation, geometric CAD, calculation, etc., can solve problems such as heavy calculation tasks, grid distortion, and difficulty in dividing hexahedral grids, so as to improve convergence and calculation speed, The effect of improving stability and efficiency, fast and accurate stiffness calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

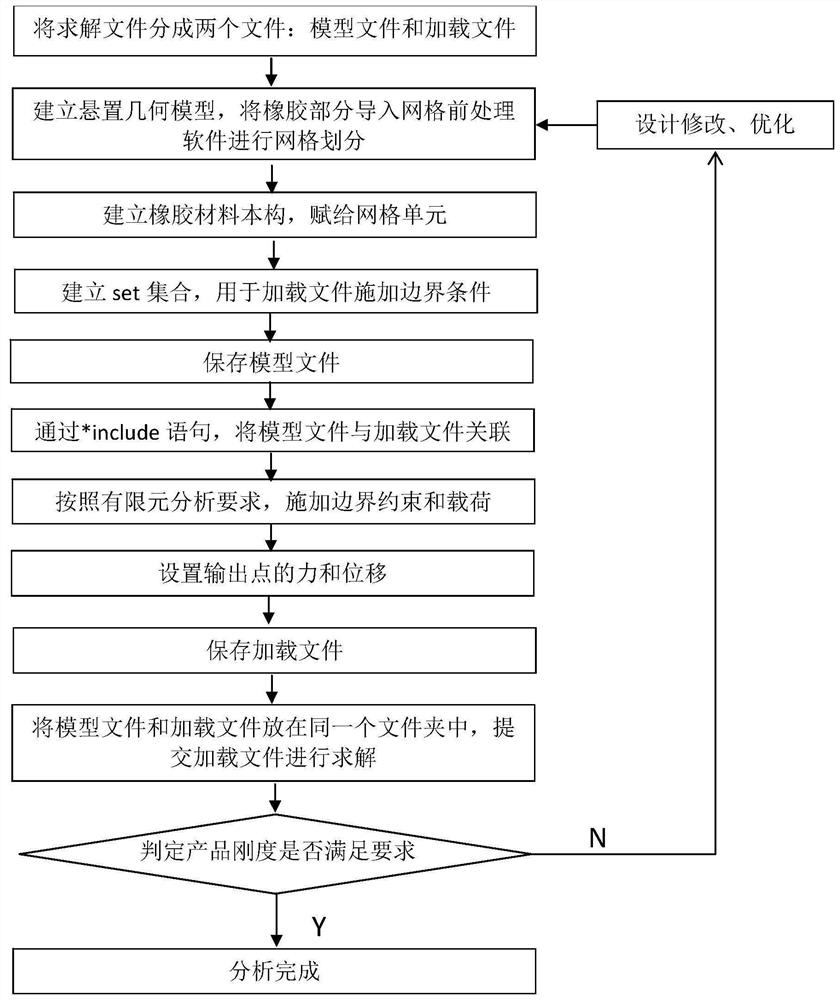

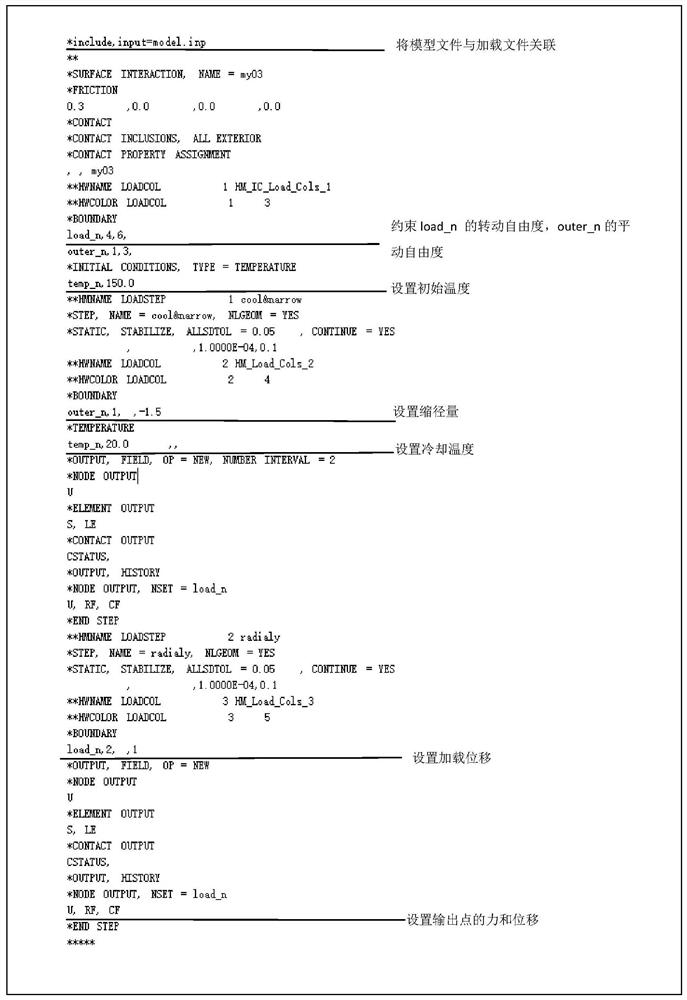

[0031] Such as figure 1 Shown, a kind of rubber-metal composite suspension rigidity rapid analysis method of the present invention, its steps comprise:

[0032] Step S1: setting the solution file;

[0033] The solution file includes two files: a model file and a loading file; the model file includes grid information, material information, and unit collection; the loading file includes boundary constraints, loads, and output.

[0034] Step S2: creating a suspension geometric model;

[0035] For an analysis and calculation, the operator (such as a CAE engineer) only needs to perform model pre-processing, and only retain the suspension rubber part, and then divide the tetrahedral second-order unit; import the rubber part into the mesh pre-processing software for mesh division;

[0036] Step S3: establishing a rubber hyperelastic const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com