Encapsulation method and system for nuclear industry radioactive material container

A packaging method and radioactive technology, applied in nuclear engineering, portable protective containers, etc., can solve problems such as easy leakage of radioactive materials, reduce the risk of exposure to radiation, reduce labor costs, and improve packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

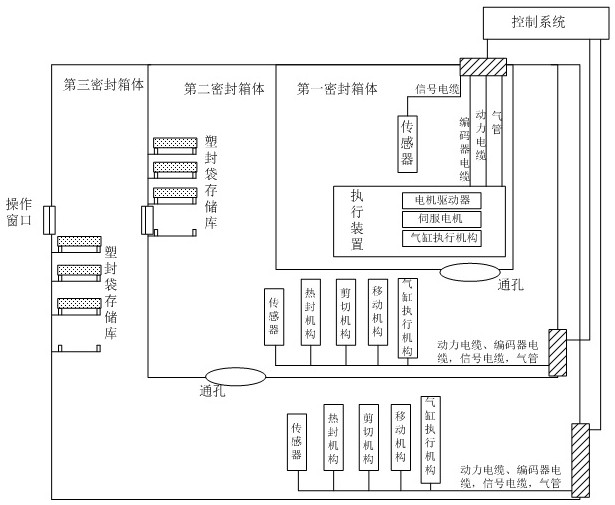

[0047] The packaging system of the nuclear industry material container in the embodiment of the present invention includes: a plurality of N sealed boxes nested in sequence, the innermost first sealed box is connected to the transfer channel of the container to be packaged, and each of the N sealed boxes is There are multiple moving structures, and all moving mechanisms are connected to the control systems outside all sealed boxes; adjacent nested sealed boxes are in an isolated state during the packaging process; all sealed boxes are in a negative pressure environment;

[0048]The second to Nth sealed boxes are provided with a plastic bag assembly and a detector for detecting radiation information of radioactive materials, and the multiple moving structures include: a heat-sealing moving mechanism, a shearing moving mechanism;

[0049] The bottom plates of the first sealed box to the N-1th sealed box are all provided with through holes for the container / packaged container to p...

Embodiment 2

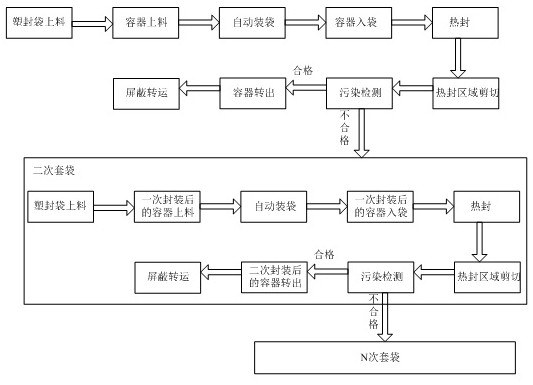

[0062] Based on the aforementioned packaging system, an embodiment of the present invention also provides a method for packaging radioactive material containers in the nuclear industry. The execution subject of the method may be a control system. Always isolate during packaging or container bagging. The packaging method of this embodiment may include the following steps, such as Figure 2A with Figure 2B shown.

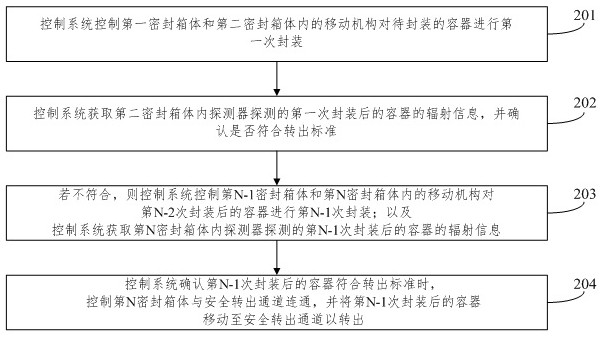

[0063] 201. The control system controls the moving mechanisms in the first sealed box and the second sealed box to perform the first packaging of the container to be packaged;

[0064] 202. The control system obtains the radiation information of the first sealed container detected by the detector in the second sealed box, and confirms whether the transfer-out standard is met;

[0065] 203. If not, the control system controls the N-1 sealed box and the moving mechanism in the N-th sealed box to perform the N-1 package on the container after the N-2 package; and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com