Ground clearance monitoring system for crushing blades of cassava stem crushing and field returning machine

A monitoring system and a technology for crushing blades, which are used in radio wave measurement systems, satellite radio beacon positioning systems, harvesters, etc. The effect of information intelligence level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

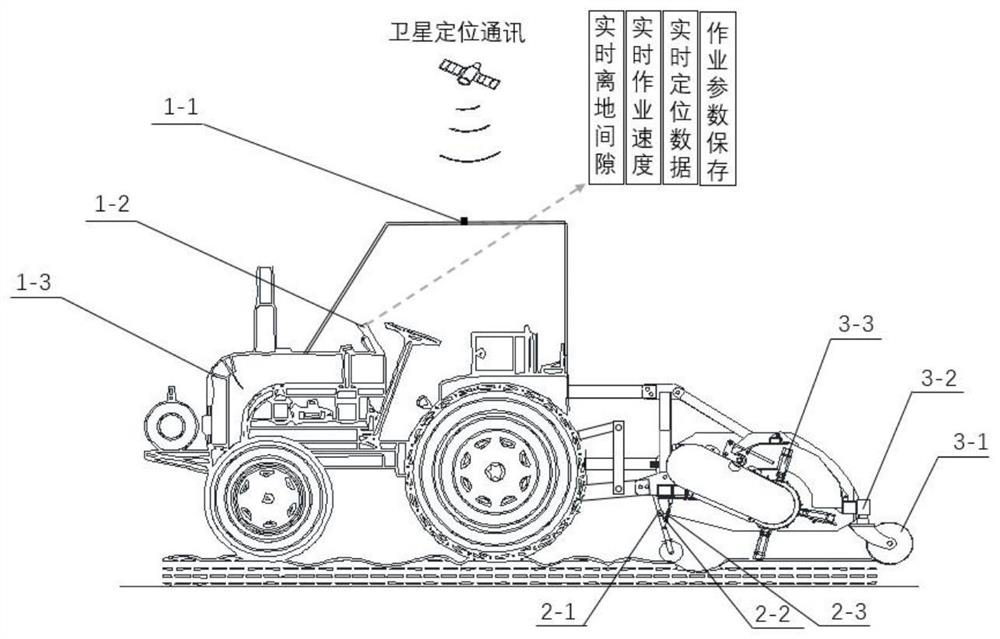

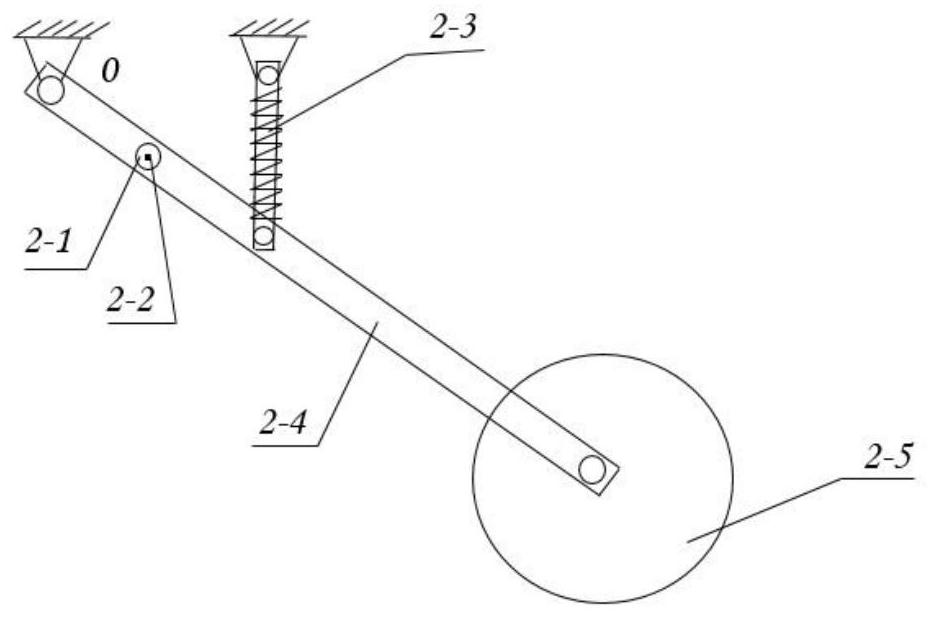

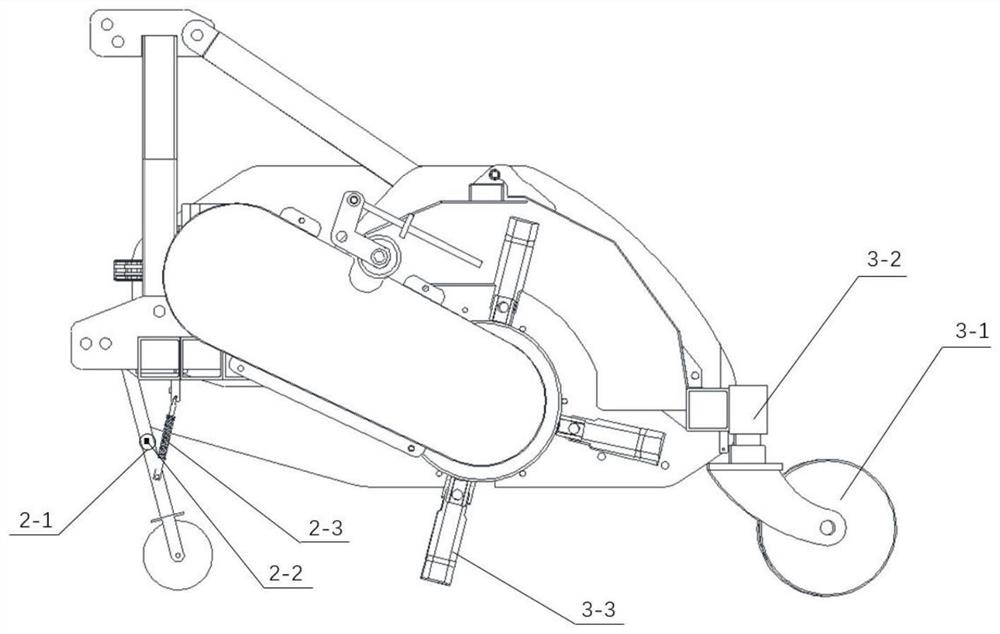

[0021] Below, the scheme of the present invention will be described in detail in conjunction with the accompanying drawings and a cassava stalk crushing and field return machine crushing blade ground clearance monitoring system and the cassava stalk crushing and field return machine monitoring system loaded with the above-mentioned system, such as Figure 1 to Figure 5 shown.

[0022] Cassava stalk crushing and returning machine monitoring system such as figure 1 As shown, it consists of three parts: data acquisition, control, and data monitoring. The data acquisition part includes the posture detection device 2-2 and the microprocessor part, and is mainly responsible for the posture detection of the profiling detection mechanism and the receiving, processing and sending of posture data. The control part consists of the microprocessor, relay, solenoid valve, and hydraulic cylinder 3-2. It is mainly responsible for receiving and processing control commands, and controlling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com