Efficient chemical material screening machine

A screening machine, chemical technology, applied in the direction of filtration, chemical instruments and methods, solid separation, etc., can solve the problems of inapplicability to different sizes of products, arm soreness during operation time, and small application range, so as to speed up the screening speed and avoid Uneven particle size and high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

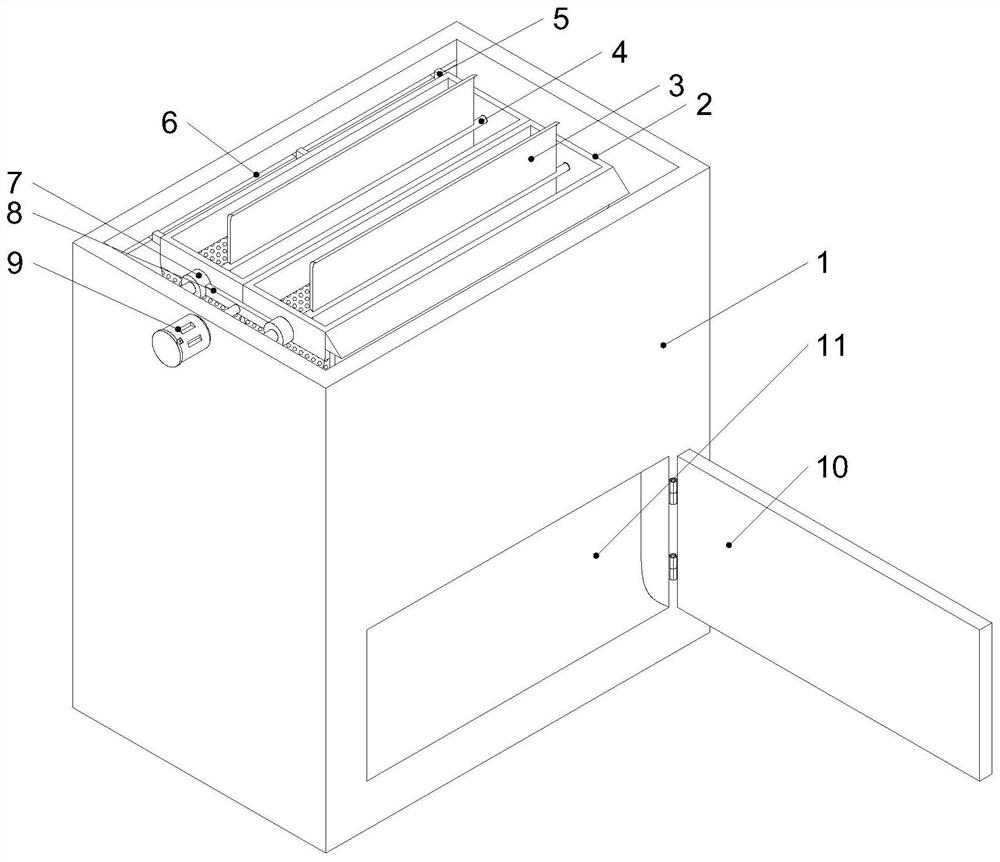

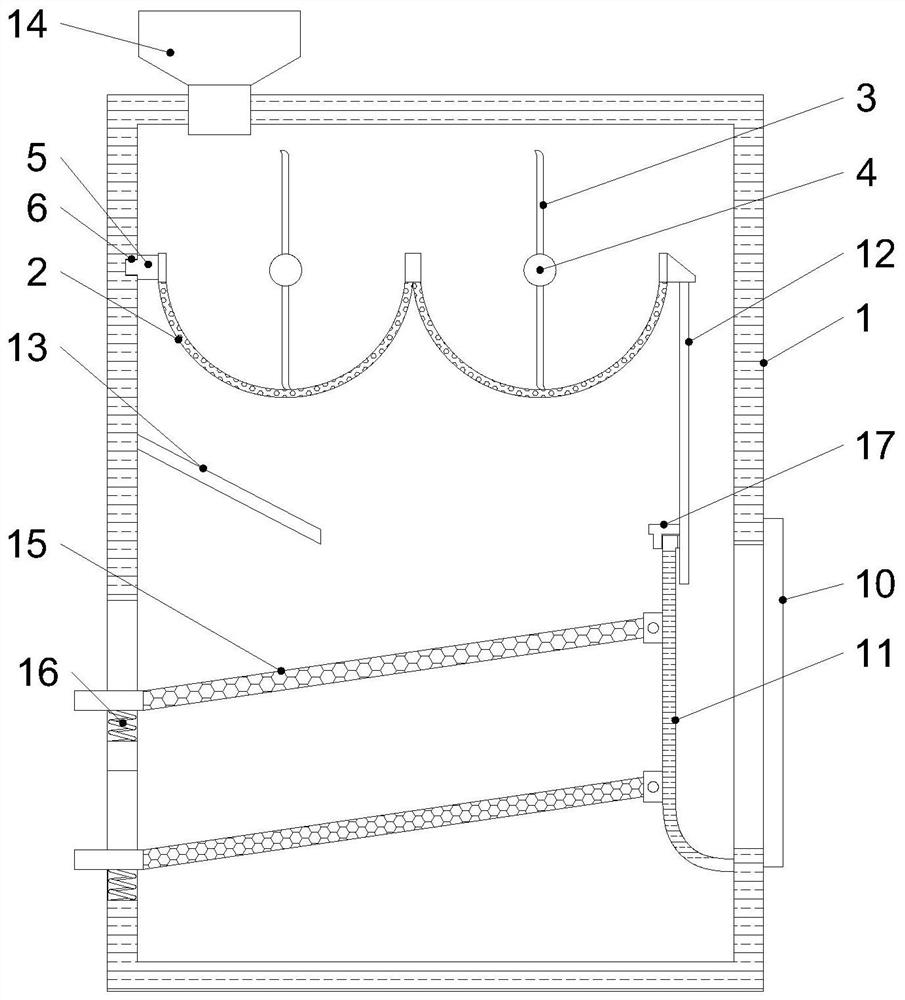

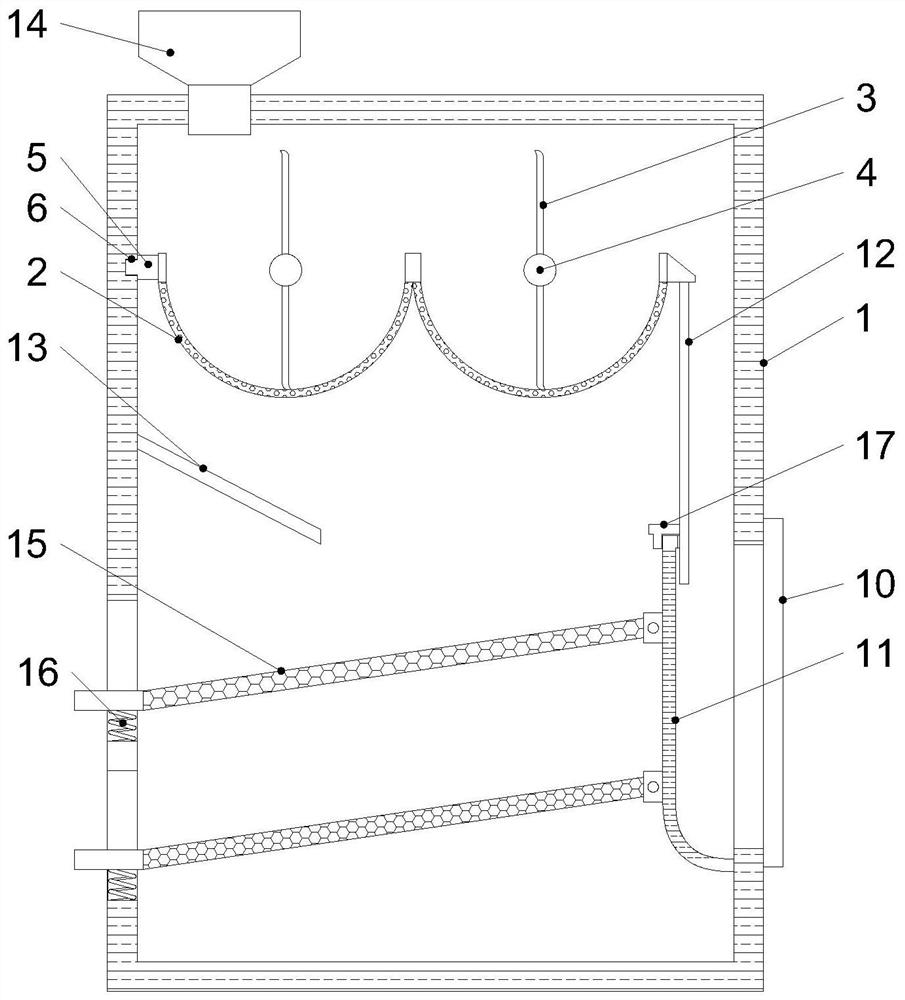

[0019] Example: such as Figure 1-3 As shown, a kind of high-efficiency chemical material screening machine of the present invention comprises a screening machine shell 1, and two mutually symmetrical screening boxes 2 are arranged in the screening machine casing 1, and one side of the screening box 2 is connected to each other, and the screening box 2 The side away from each other is slidingly connected to the screening machine shell 1, and the side of the screening box 2 far away from the screening machine shell 1 is fixedly connected with a guide plate 12, and the two ends of the screening box 2 are respectively fixedly connected with sleeves 7, And the sleeve 7 is provided with a main shaft 4, the bottom of the sieve box 2 is provided with two parallel sieve plates 15, and the bottom side of the screening machine shell 1 is equipped with a blanking plate 11, and the blanking plate 11 is connected with the The both sides inner walls of the screening machine shell 1 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com