Plate surface in-hole cleaning device and cleaning method

A technology for cleaning devices and surface holes, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using gas flow, etc., can solve the problem that powder cannot be cleaned effectively and quickly, so as to prevent accumulation and improve stirring efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

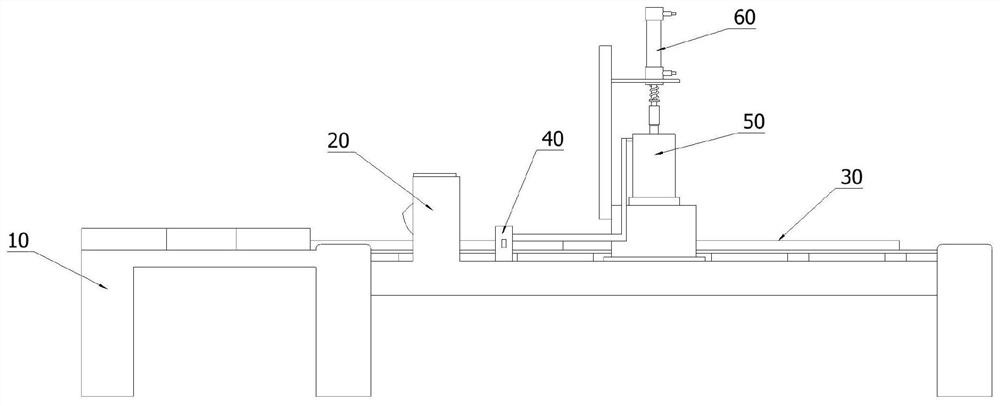

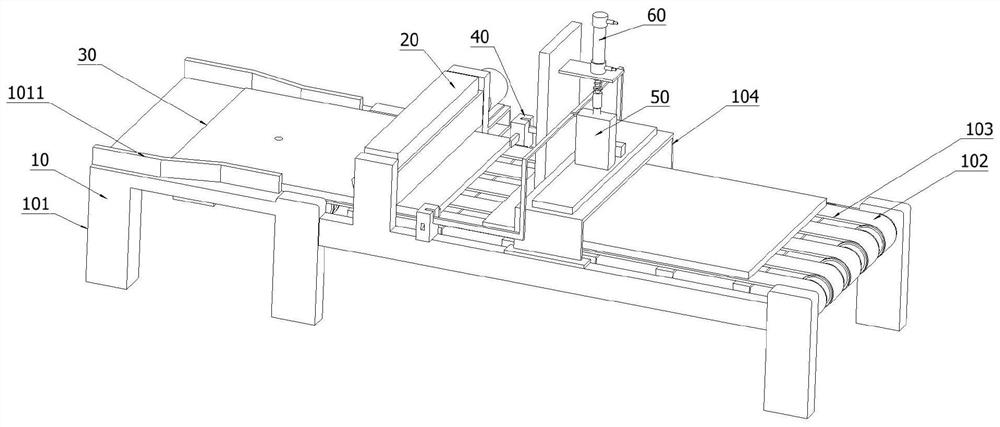

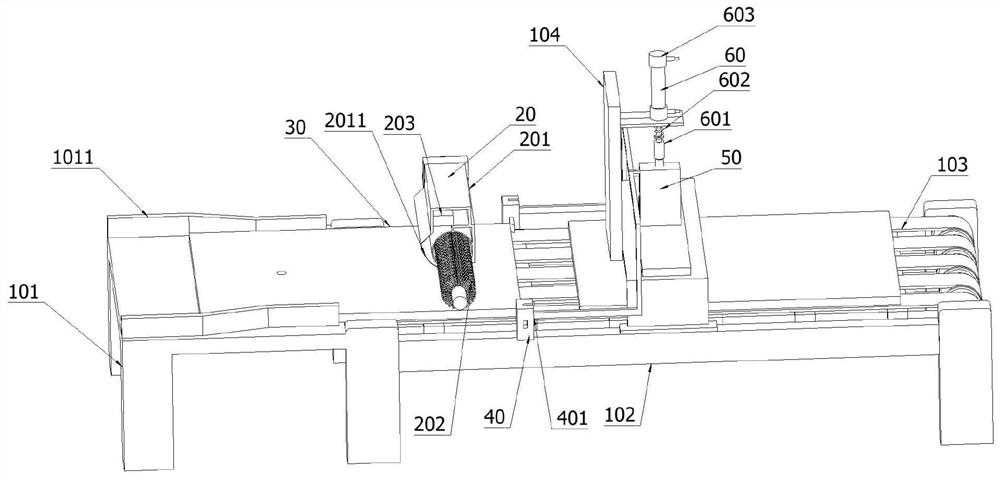

[0047] like figure 1 , 3 , 4, 5, and 6, this embodiment discloses a device for cleaning the surface holes of a plate 30, including: a machine body 10, a rolling brush device 20, a dust detection device 50, a driving device 60, a rotating device 70, and a dust suction device 80. The machine body 10 is set on a plane, and the machine body 10 includes: a first transport frame 101, a second transport frame 102, a conveyor belt 103, and a support frame 104. The first transport frame 101 is set on a plane, and the surface of the first transport frame 101 is flat On the surface, the surface of the first conveying frame 101 is provided with a guide plate 1011, the guide plate 1011 is fixedly connected with the first conveying frame 101, the guide plate 1011 is funnel-shaped, one end of the guide plate 1011 is constricted, and the other end of the guide plate 1011 is flared. The width of the neck-shaped end of the guide plate 1011 is greater than the width of the board 30 . The secon...

Embodiment 2

[0058] Same as Embodiment 1, also includes such as Figure 4 As shown, the limiting device 40 is arranged above the second conveying frame 102, the limiting device 40 is fixedly connected with the second conveying frame 102, the limiting device 40 is located in the middle of the roller brush device 20 and the dust detection device 50, the limiting device 40 includes: a limit case 401, a positioning plate, and a limit rod 402. The limit case 401 is arranged on both sides of the second conveying frame 102. There are two limit cases 401, and the two limit cases 401 are arranged symmetrically on the second The two side surfaces of the two conveying racks 102, the inside of the spacer housing 401 are provided with accommodating space; the positioning plate is arranged on the inside of the spacer housing 401, and the positioning plate is horizontally placed in the inside of the spacer housing 401, and the positioning plate stretches out to limit the position. One end of the shell 40...

Embodiment 3

[0061] like Figure 8 As shown, there is also provided a cleaning method for the cleaning device in the surface hole of the plate 30 at last, comprising the following steps:

[0062] Conveying the plate 30, placing the plate 30 on the first conveying rack 101, moving the plate 30 to the second conveying rack 102 through an external push mechanism, and passing through the first conveying rack 101 before the plate 30 enters the second conveying rack 102 The guide plate 1011 adjusts the position of the plate 30 so that the feeding process of the plate 30 remains stable;

[0063] To clean the surface, the roller brush shaft 202 of the roller brush device 20 is rotated by the external driving device 60 while the plate 30 is moving, and the surface of the plate 30 is brushed by the brush on the outer periphery of the roller brush shaft 202. When removing part of the impurities on the surface of the plate 30 does not affect the judgment of the positioning device, the removed impurit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com