Lifting type hydraulic cylinder barrel inner wall spraying and cleaning equipment

A cylinder inner wall, spray cleaning technology, applied to lighting and heating equipment, cleaning methods using liquid, cleaning hollow objects, etc., can solve the problems of poor cylinder cleaning effect and high production cost, so as to improve work efficiency and speed up Drying and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

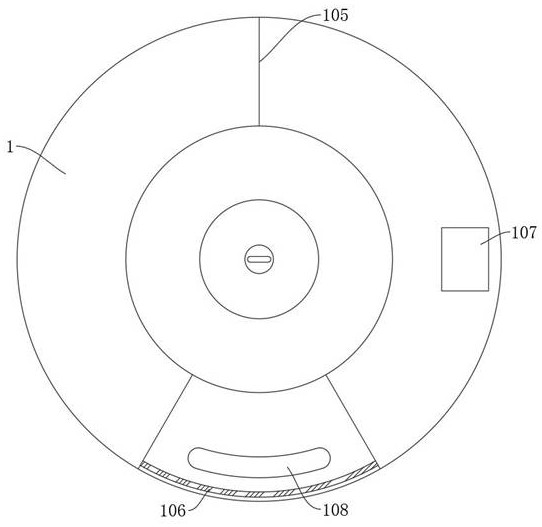

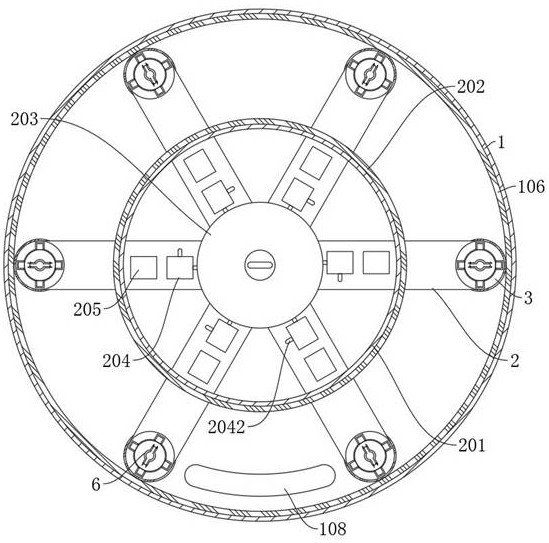

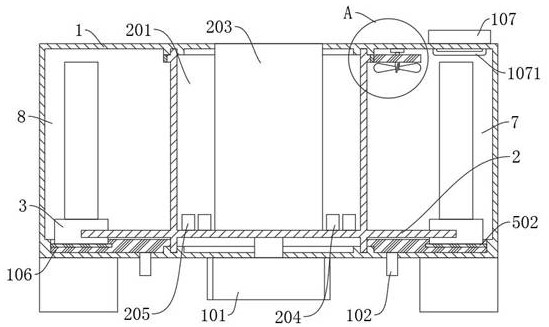

[0031] refer to Figure 1-3 with Figure 5-7, a lifting type hydraulic cylinder inner wall spray cleaning equipment, including a working box 1, a water pump 204 and an ultrasonic generator 205, the working box 1 is divided into a cleaning chamber 8 and a drying chamber 7 by an isolation film 105, and the working box 1 A mounting frame 2 is connected in rotation, and the water pump 204 and the ultrasonic generator 205 are fixedly connected to the mounting frame 2. The water storage tank 203 and the positioning platform 3 are fixedly connected to the mounting frame 2. The positioning platform 3 is provided with a lifting groove 301. The side wall of the groove 301 is provided with a clamping groove 302, and a lifting column 4 is slidably connected in the lifting groove 301. The two ends of the lifting column 4 are respectively fixedly connected with a placing table 401 and a magnetic disk 404, and the inner wall of the bottom of the work box 1 is fixedly connected with a magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com