Welding gun angle adjusting device

An angle adjustment device, the technology of the adjustment device, applied in the directions of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problem of high adjustment requirements, achieve the effect of reducing position requirements, tightening or loosening labor-saving, convenient and easy to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

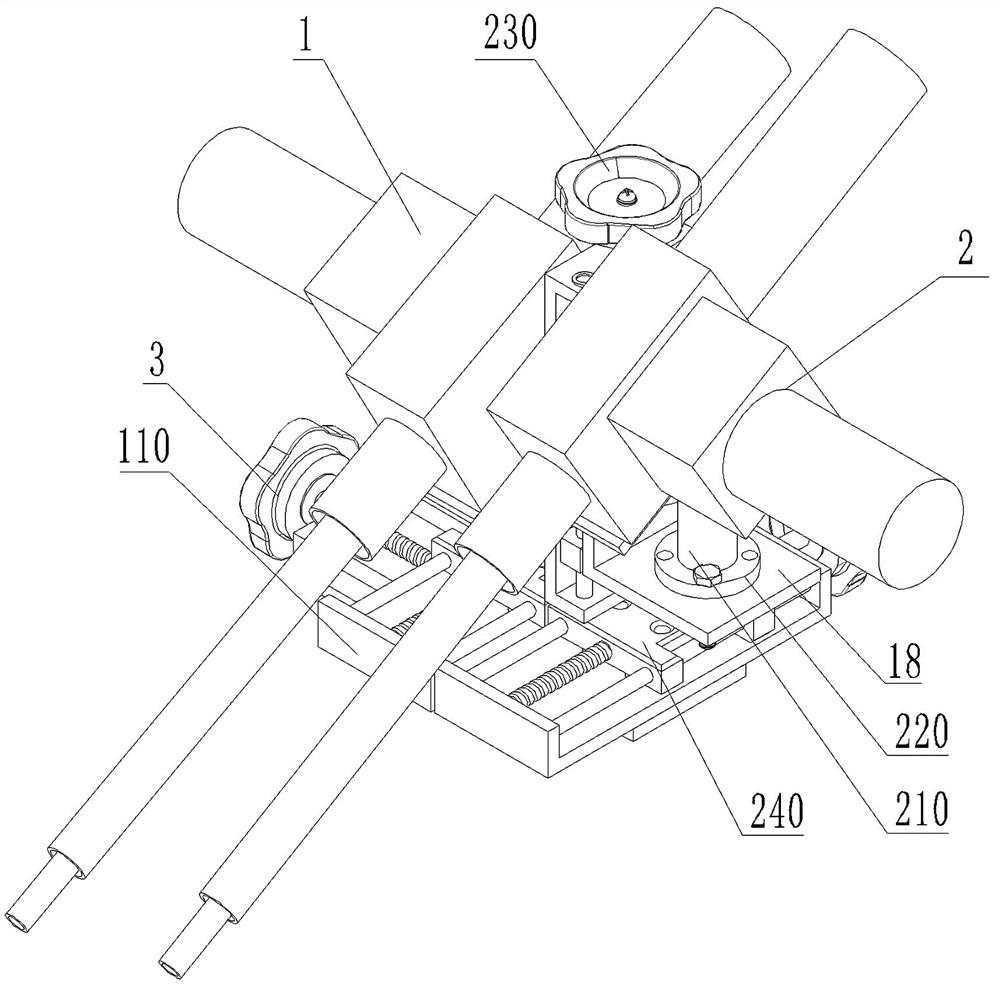

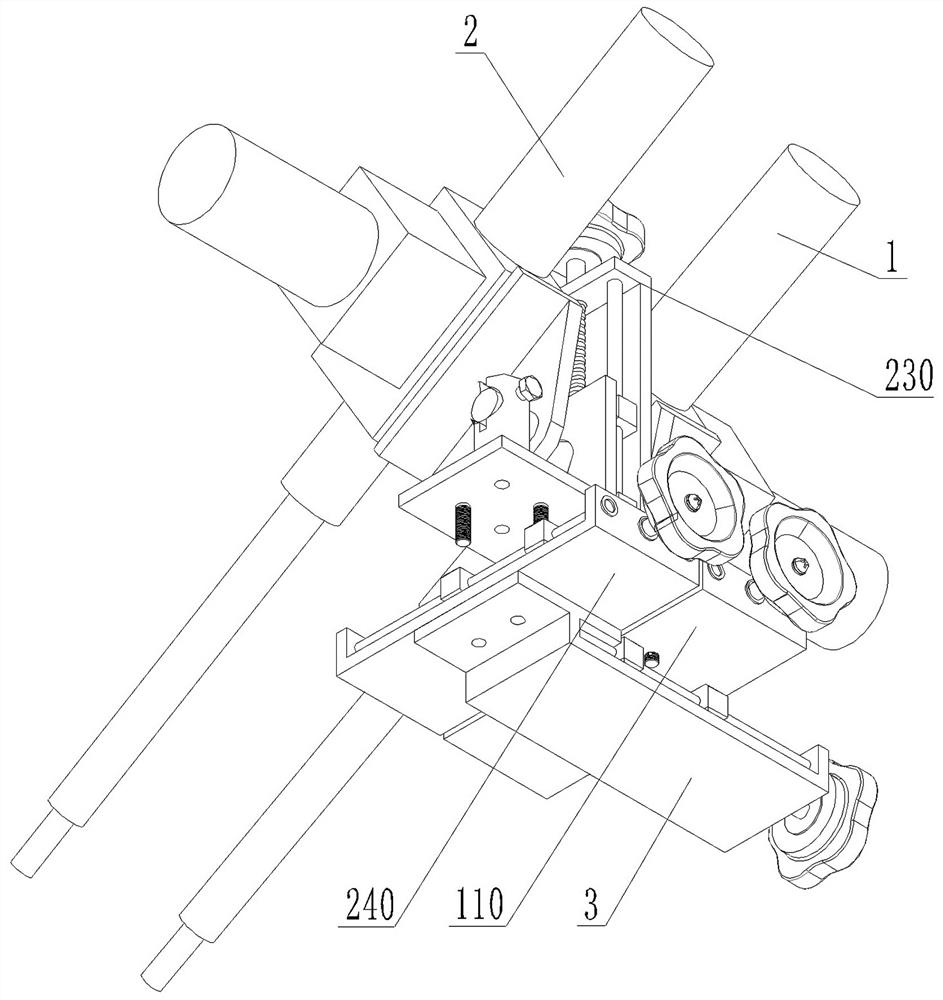

[0037] A welding torch angle adjustment device, please refer to figure 1 and figure 2 , including the first welding torch assembly 1 and the second welding torch assembly 2, the first welding torch assembly 1 and the second welding torch assembly 2 have the same structure, and both include a welding wire straightening mechanism, a wire feeding motor, a welding torch, a conductive tip, a welding wire , This kind of welding gun assembly has the advantages of straightening welding wire and automatic wire feeding, which can effectively ensure the welding quality. The present invention also includes a first pitch adjustment device, a first front and rear adjustment device, a first screw slide 110, a second pitch adjustment device 210, a second front and rear adjustment device 220, a second screw slide 230, a third screw slide Lead screw slide table 240 and the 4th lead screw slide table 3.

[0038] The upper end surfaces of the sliding plates of the above-mentioned screw slides ...

Embodiment 2

[0049] A welding torch angle adjustment device, please refer to figure 1 and figure 2 , including the first welding torch assembly 1 and the second welding torch assembly 2, the first welding torch assembly 1 and the second welding torch assembly 2 have the same structure, and both include a welding wire straightening mechanism, a wire feeding motor, a welding torch, a conductive tip, a welding wire , This kind of welding gun assembly has the advantages of straightening welding wire and automatic wire feeding, which can effectively ensure the welding quality. The present invention also includes a first pitch adjustment device, a first front and rear adjustment device, a first screw slide 110, a second pitch adjustment device 210, a second front and rear adjustment device 220, a second screw slide 230, a third screw slide Lead screw slide table 240 and the 4th lead screw slide table 3.

[0050] The upper end surfaces of the sliding plates of the above-mentioned screw slides ...

Embodiment 3

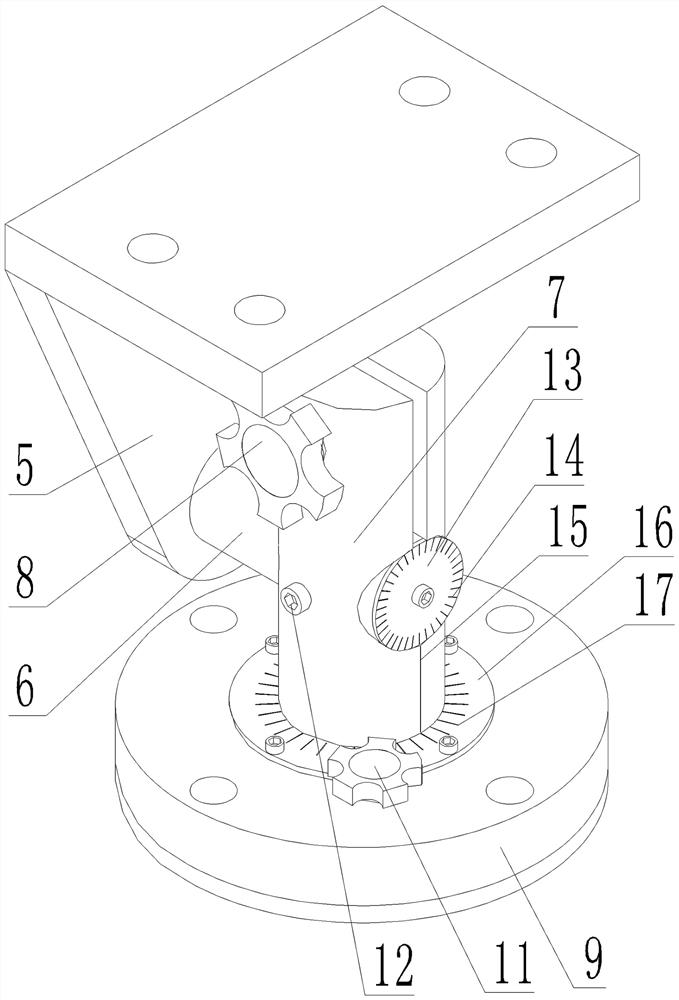

[0065] see Figure 8 , The difference between this embodiment and Embodiment 1 is that the structure in this embodiment also includes a fifth screw slide 19, the sliding structure of the fifth screw slide 19 is an L-shaped block 1901, and on the L-shaped block 1901 Also be provided with guide through hole and leading screw through hole, and the direction of guide through hole and leading screw through hole is all perpendicular to the motion direction of the 5th leading screw slide table 19, is provided with threaded pipe in the leading screw through hole, the threaded pipe An internal thread structure is provided on the inner wall. Guide rod 20 is arranged in the guide through hole of L-shaped block 1901, and the guide through hole of L-shaped block 1901 and guide rod 20 are cylindrical structure, and the diameter of both is identical, and guide rod 20 is positioned at L-shaped block 1901 side A flat plate 21 is provided at one end of the guide rod 20, and a connection block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com