Positioning and clamping tool for shell part

A positioning clamping and tooling technology, which is applied in the field of positioning clamping tooling, workpiece processing, positioning and clamping tooling of shell parts, can solve the problems such as difficulty in guaranteeing dimensional accuracy and shape and position tolerance, so as to improve processing efficiency and reduce deformation effect, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

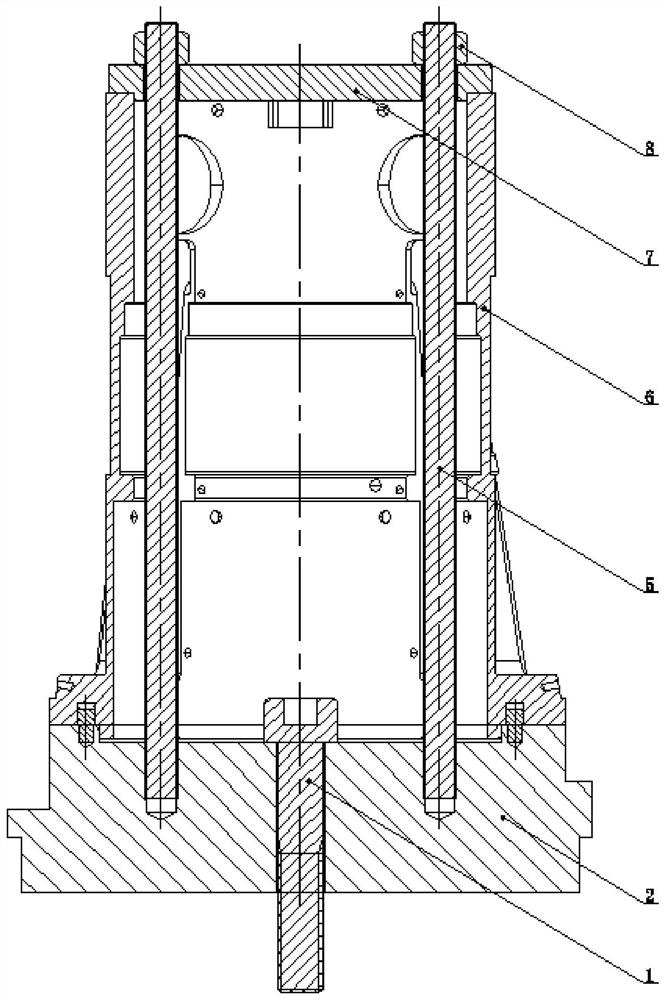

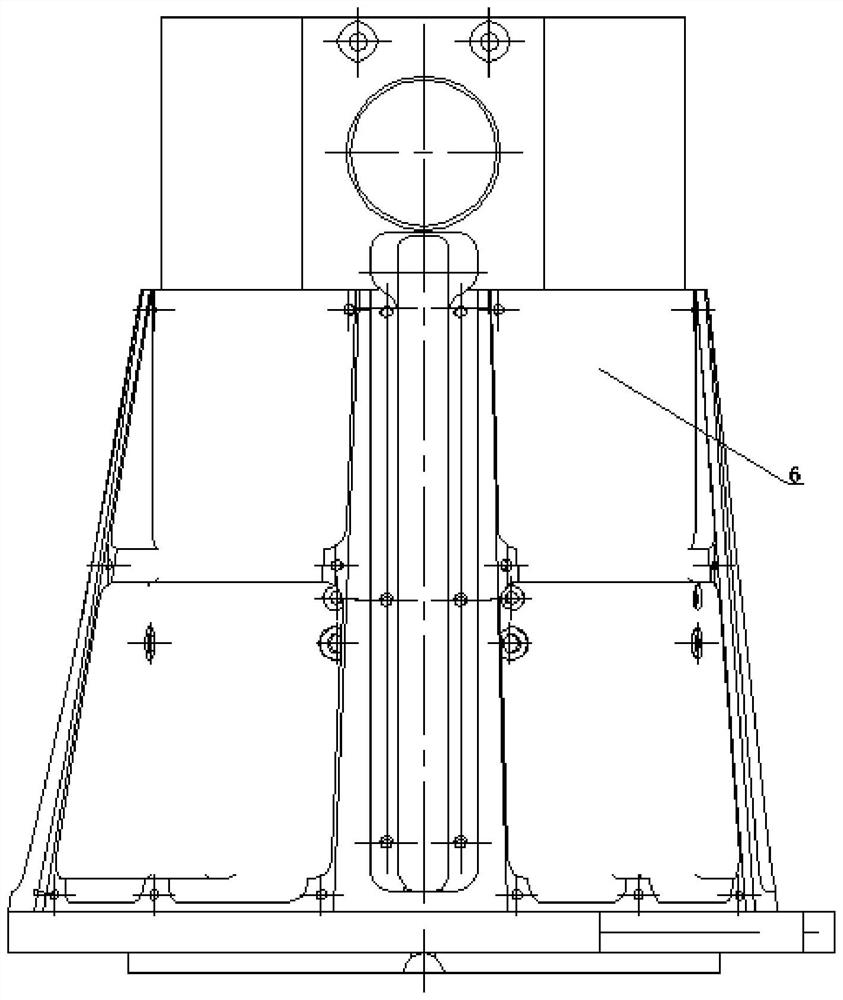

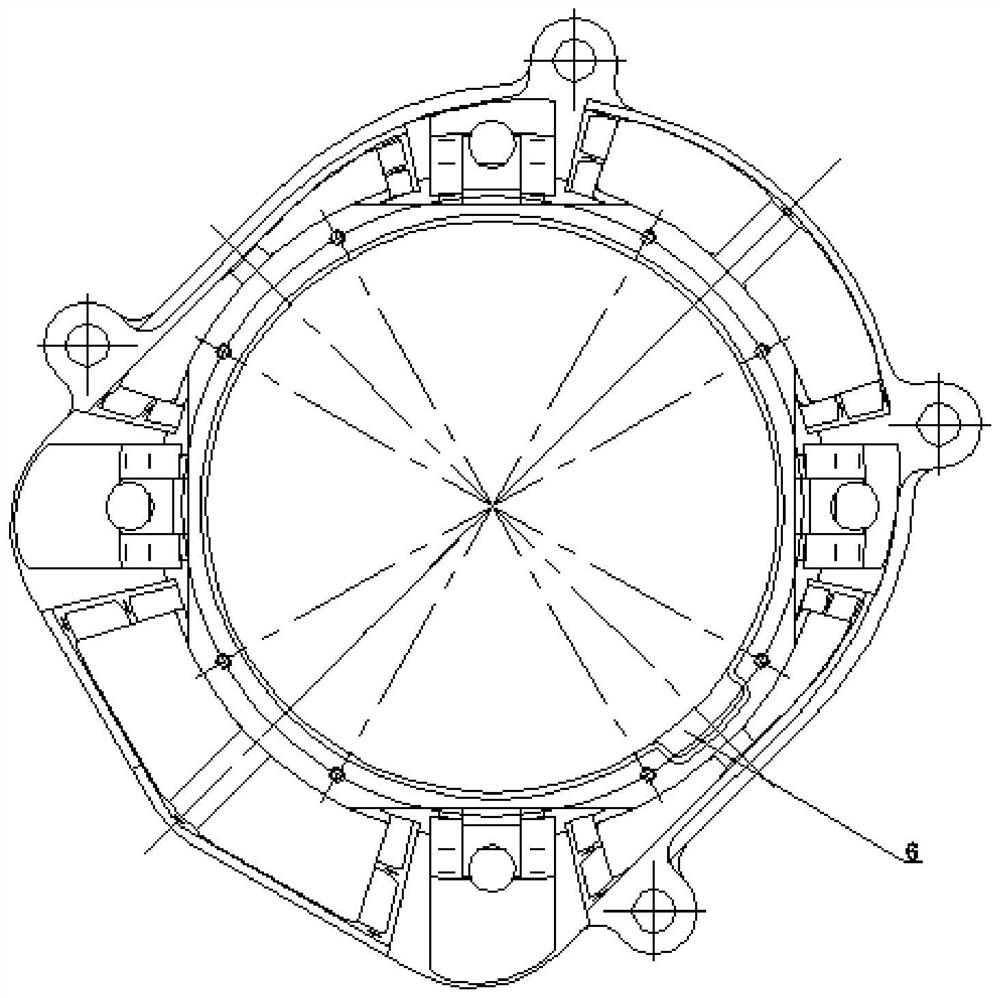

[0021] Specific implementation mode one: combine Figure 1-Figure 11 Describe this embodiment, the positioning and clamping tooling of shell parts described in this embodiment, which includes connecting screws 1, tooling base 2, positioning pin assembly, tooling gland 7, multiple studs 5 and multiple Nut 8; the tooling gland 7 is a plate body whose upper end surface and lower end surface are parallel, the lower end surface of the tooling gland 7 is processed with protrusions, and the tooling gland 7 is uniformly processed with a plurality of through holes, and the tooling base 2 is the upper end surface The plate body parallel to the lower end surface, the upper end surface of the tooling base 2 is processed with grooves, the groove bottom of the upper end surface groove of the tooling base 2 is processed with through holes and multiple threaded holes, and the side wall of the upper end surface groove of the tooling base 2 Blind holes are processed, and the positioning pin ass...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 1-Figure 7 Describe this embodiment, a positioning and clamping tool for shell parts. The cooling joint 2 includes a connecting plate and a coolant connection end. It is arranged in cooperation with the low-end convex shape of the part 6 to ensure the accuracy of the clamping and positioning of the part 6 by the positioning and clamping tooling. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 and Figure 10 Describe this embodiment, a positioning and clamping tool for shell parts, the positioning pin assembly is two first positioning pins 3, the diameter of the first positioning pin 3 is 5mm, the positioning pin mounting hole at the bottom of the part 6 and the tooling base 2 The top blind hole is positioned by the first positioning pin 3. During rough machining, it is only necessary to insert the first positioning pin 3 into the positioning pin hole where the first positioning pin 3 is installed at the bottom of the part 6 and insert the first positioning pin 3 at the top of the tooling base 2. The blind holes are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com