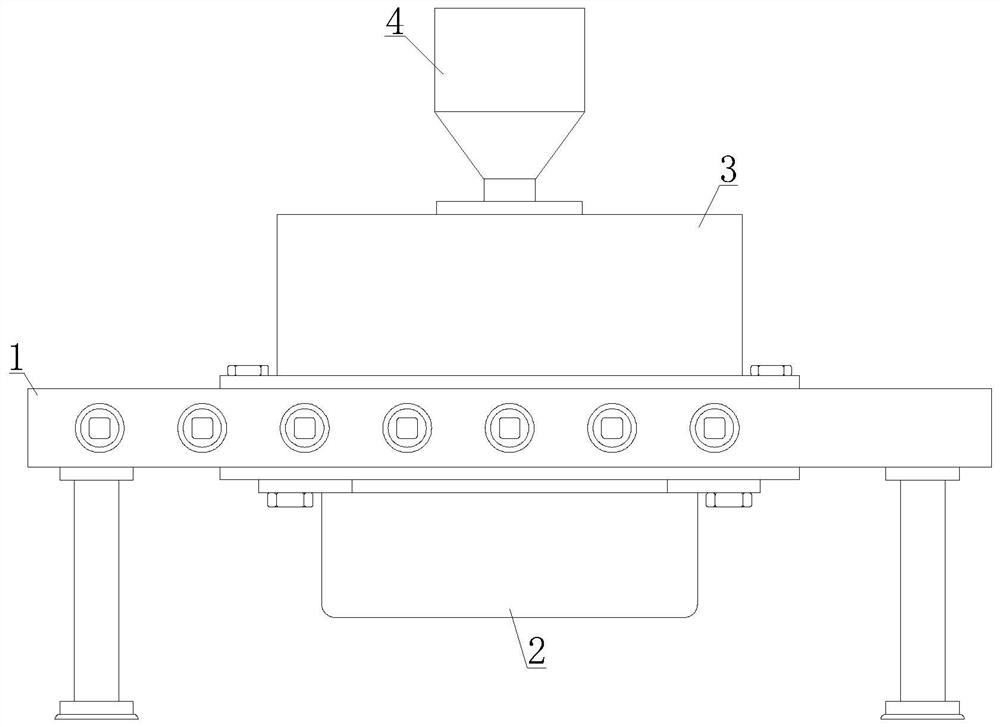

Arc-shaped chemically-toughened glass surface sand blasting device and implementation method thereof

A technology of chemically tempered glass and surface sandblasting, which is applied to explosion generating devices, used abrasive treatment devices, spray guns, etc. High efficiency, complete and reasonable structure, and short brushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

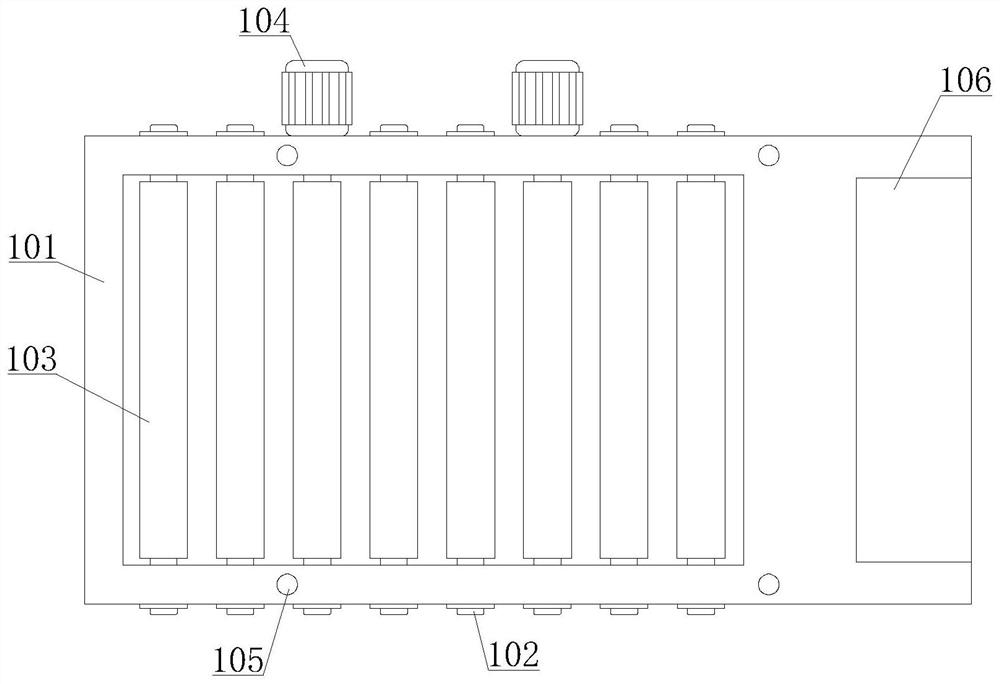

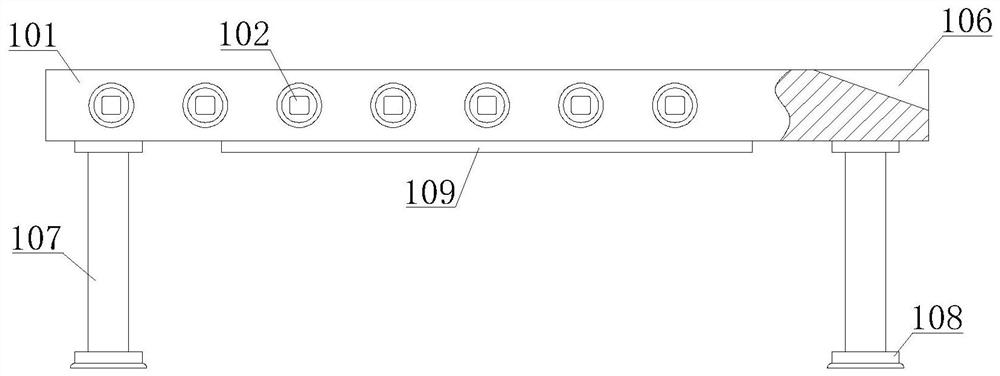

[0032] In order to better demonstrate the implementation process of the arc-shaped chemically tempered glass surface sandblasting device, this embodiment now proposes an implementation method of the arc-shaped chemically tempered glass surface sandblasting device, including the following steps:

[0033] Step 1: Place the curved glass on the guide roller 103 in the guide base 1, start the driving motor 104, and use the rotation of the guide roller 103 to transport the curved glass to the inner side of the surface sandblasting mechanism 3;

[0034] Step 2: Adjust the position of the horizontal slider 371 on the horizontal slider 372, pour the sandblasting raw materials into the external hopper 4 on the top, so that the sandblasting raw materials enter into the Sand blasting assembly 37;

[0035] Step 3: Control the hydraulic telescopic rod 374 to descend through the hydraulic drive assembly 373, so that the sandblasting head 378 contacts the curved glass surface, and spray the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com