Anti-fatigue power connection structure for lifting type charging pile

A technology for power connection and charging pile, applied in the field of anti-fatigue power connection structure for lift-type charging piles, can solve the problems of poor heat dissipation of power lines, affecting charging efficiency of charging piles, and short service life of power lines, etc. Improve charging efficiency and ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

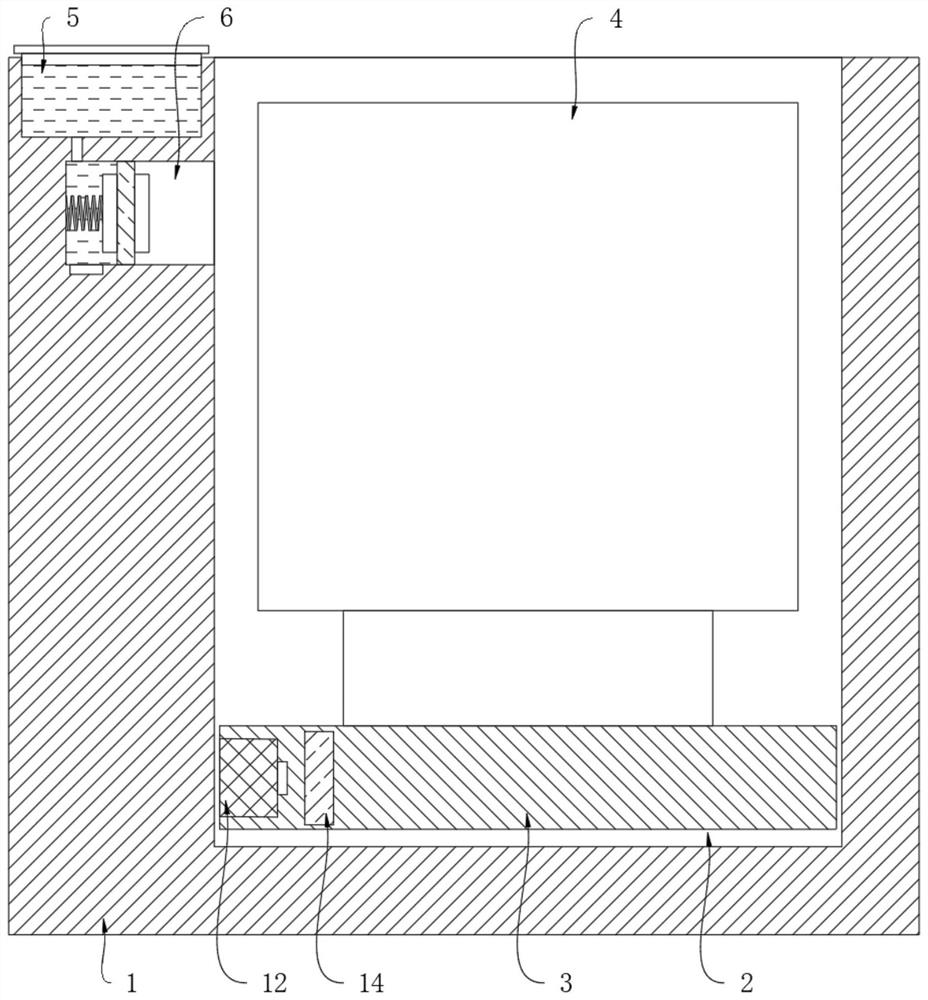

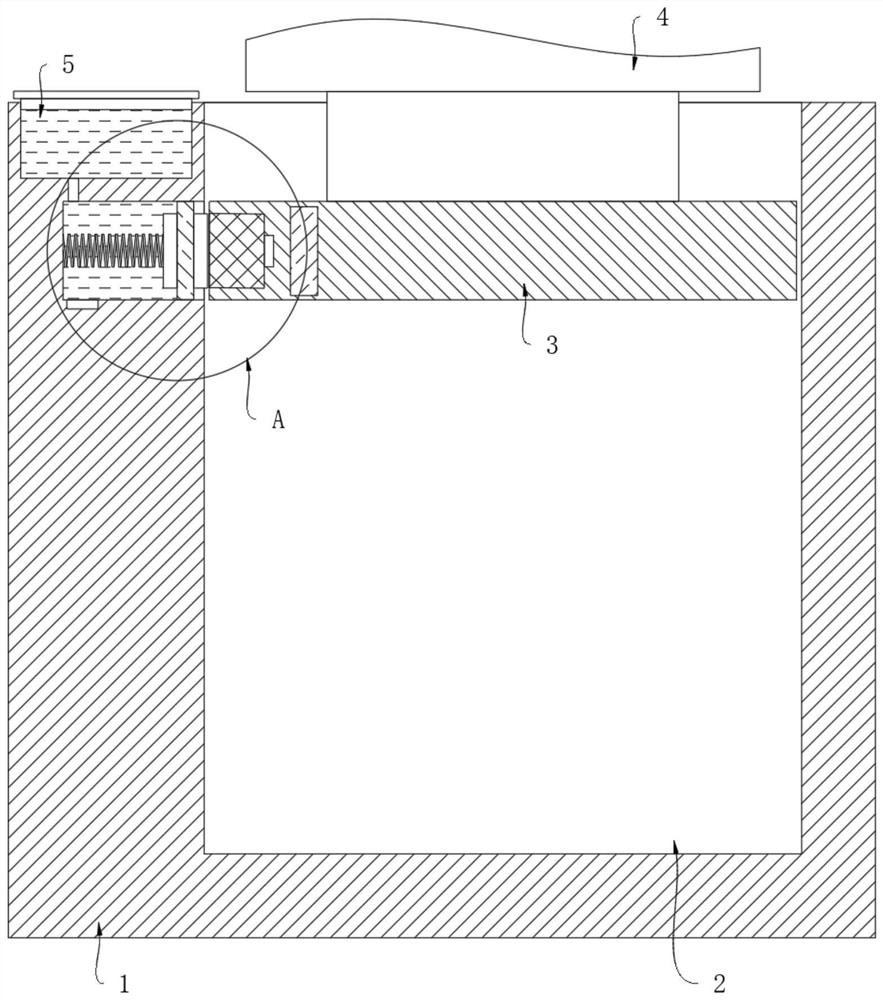

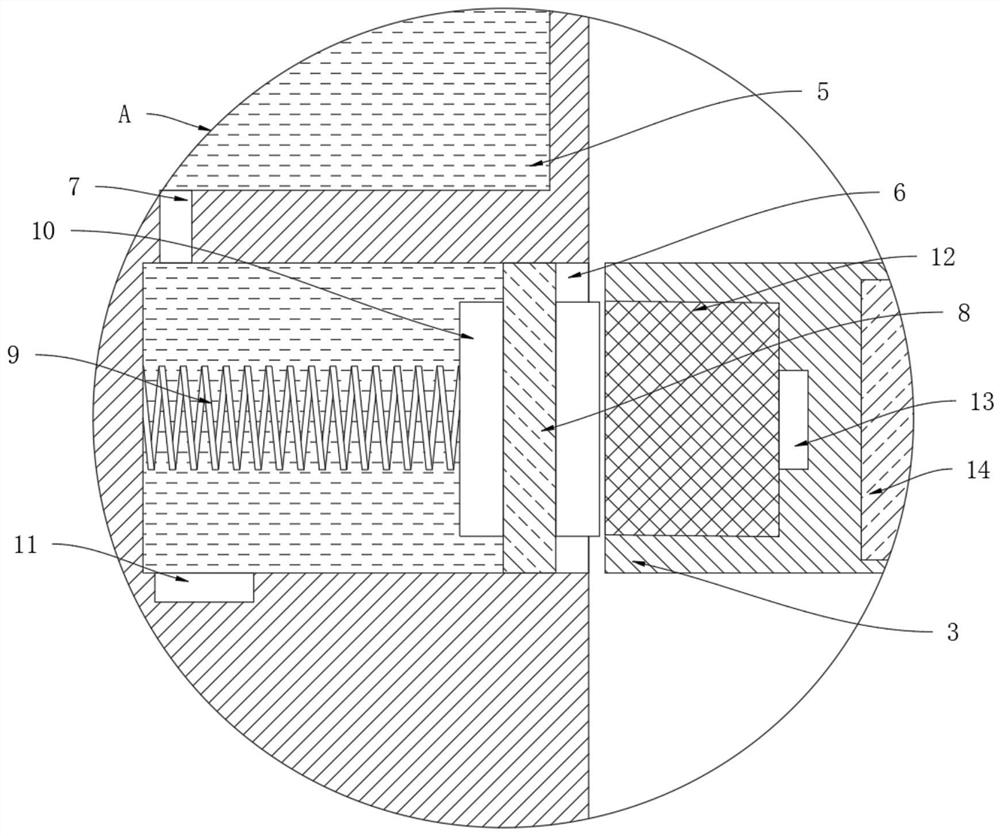

[0021] refer to Figure 1-3 , an anti-fatigue power connection structure for a lifting charging pile, including a foundation 1 and a charging pile body 4, a storage tank 2 is opened in the foundation 1, and a load-bearing plate 3 for placing the charging pile body 4 is sealed and slidably connected in the storage groove 2 , a drive device is provided between the load-bearing plate 3 and the storage tank 2, the drive device is a telescopic cylinder, and the telescopic cylinder is installed on the inner bottom wall of the storage tank 2, and the output end of the telescopic cylinder is fixedly connected with the lower end surface of the load-bearing plate 3, and the load-bearing The side wall of the plate 3 is embedded with a second conductive block 12, and the second conductive block 12 is electrically connected with a power-taking terminal 13, through which power is supplied to the external new energy vehicle. The second permanent magnet block 14 corresponding to the block 12;...

Embodiment 2

[0027] refer to Figure 4 , the difference between this implementation and Embodiment 1 is that: the groove wall of the receiving groove 2 is symmetrically provided with a limit groove corresponding to the placement groove 6, and the two limit grooves are respectively located on both sides of the placement groove 6, each limit The limit blocks 15 are slidably connected in the slots, and the ends of the plurality of limit blocks 15 away from the limit slots are fixedly connected with a baffle plate 16 , and the baffle plate 16 is sealingly and slidingly connected with the groove wall of the storage tank 2 .

[0028] In this embodiment, its functional principle can be explained through the following operation mode: when the charging pile body 4 is stored in the storage tank 2, under the action of gravity of the baffle plate 16 itself, the baffle plate 16 will block the notch of the placement slot 6, Thereby can prevent the outside impurity from entering into the placement groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com