Frame longitudinal beam transfer lifting appliance and application method thereof

A longitudinal beam and frame technology, which is applied in the field of frame longitudinal beam transfer spreader, can solve the problems of low degree of automation, low safety, complicated operation, etc., and achieves the effects of high degree of automation, high safety, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

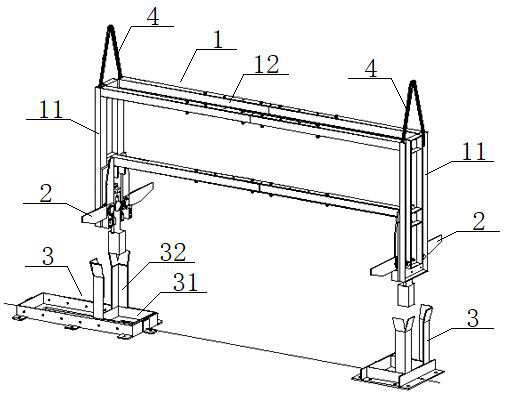

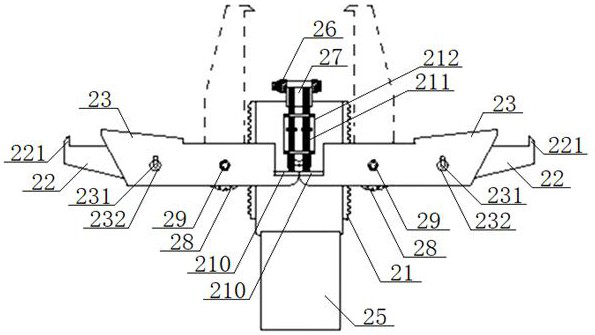

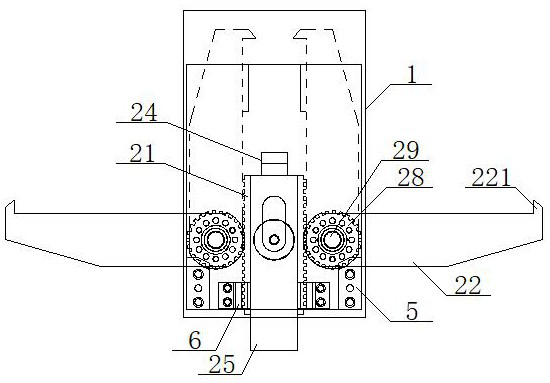

[0056] see Figure 1 to Figure 4 , a frame longitudinal beam transfer spreader, including a frame 1, a support arm device 2 and a guide base 3, the top of the frame 1 is symmetrically connected with two lifting rings 4, and the bottom of the frame 1 is symmetrically connected with two support arm devices 2. A guide base 3 is provided below the support arm device 2, and the support arm device 2 includes a tooth plate 21, two support arms 22 symmetrically arranged on both sides of the tooth plate 21, and two support arm rotation control plates 23 , the tooth plate 21 is slidingly connected with the frame 1, the top of the tooth plate 21 is connected with a fixed hook 24, the bottom of the tooth plate 21 is connected with a drop block 25, and the position above the tooth plate 21 on the frame 1 is equipped with a hook support Seat 26, the locking hook 27 that matches with fixed hook 24 is rotatably connected on the hook support 26, and the end of described support arm 22 is conne...

Embodiment 2

[0063] Basic content is the same as embodiment 1, the difference is:

[0064] see Figure 2 to Figure 6 The locking hook 27 includes a lifting plate 271 and a hook body 272 matched with the fixed hook 24, the lifting plate 271 is connected to the hook body 272 through a pair of protrusions 273, and the protrusion 273 is connected to the hook body 272 through a bolt 274. The hook support 26 is rotatably connected, and a torsion spring 275 is set on the bolt 274 between a pair of protrusions 273. One end of the torsion spring 275 rides on the hook support 26, and the other end of the torsion spring 275 rides on the hook support 26. On the upper surface of the lifting plate 271 , the top of the lifting rod 211 abuts against the lower surface of the lifting plate 271 .

Embodiment 3

[0066] Basic content is the same as embodiment 1, the difference is:

[0067] see Figure 2 to Figure 4 , the position on the shaft 29 located inside the bracket arm rotation control plate 23 is connected with a limit plate, and the bracket arm rotation control plate 23 is provided with a through hole 231, and a limit plate connected with the limit plate is inserted in the through hole 231. position pin 232; the upper surface of the bracket arm 22 away from the gear 28 is provided with a protrusion 221; the position below the bracket arm 22 on the frame 1 is connected with the bracket arm limit block 5; The positions on both sides of the plate 21 are connected with tooth plate limiting blocks 6 , and the tooth plate limiting blocks 6 are provided with limiting slots matching the tooth plate 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com