Microstructure generation method and product with microstructure on surface

A microstructure and product technology, applied in the field of microstructure generation and products with microstructures on the surface, can solve the problems of low product accuracy, poor repeatability and controllability, achieve high precision and reliability, and ensure anti-glare effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

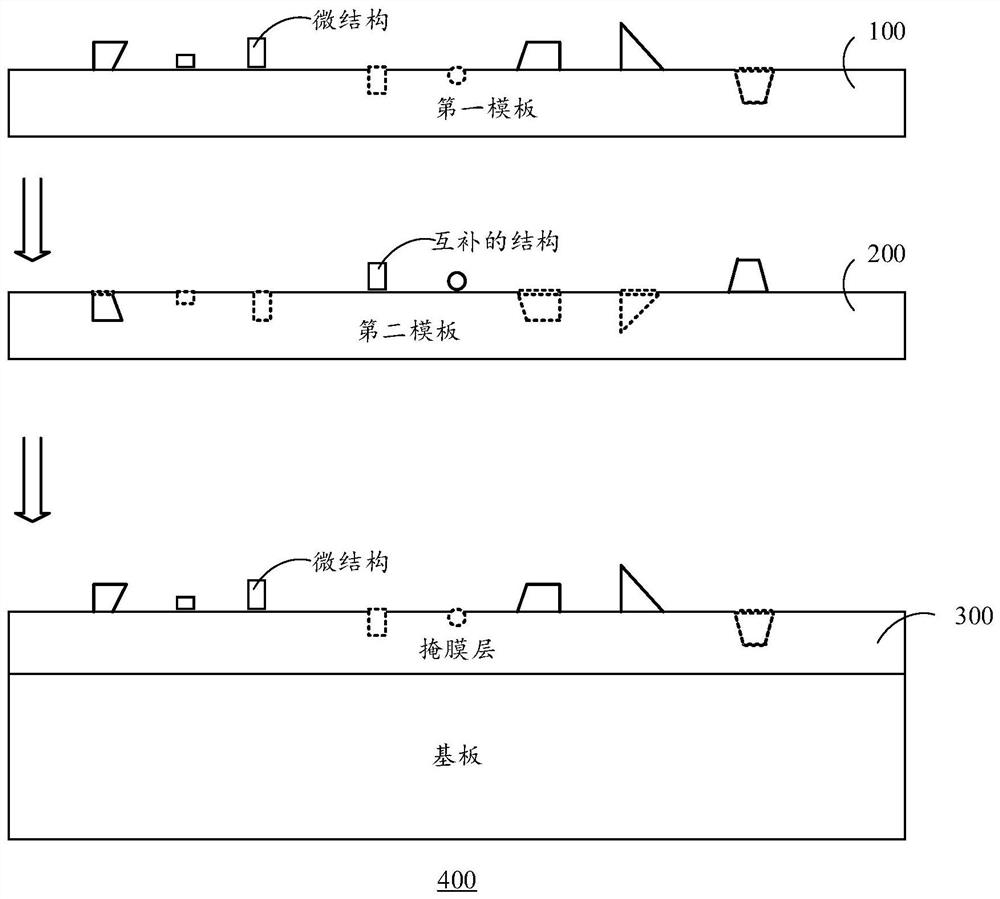

[0035] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

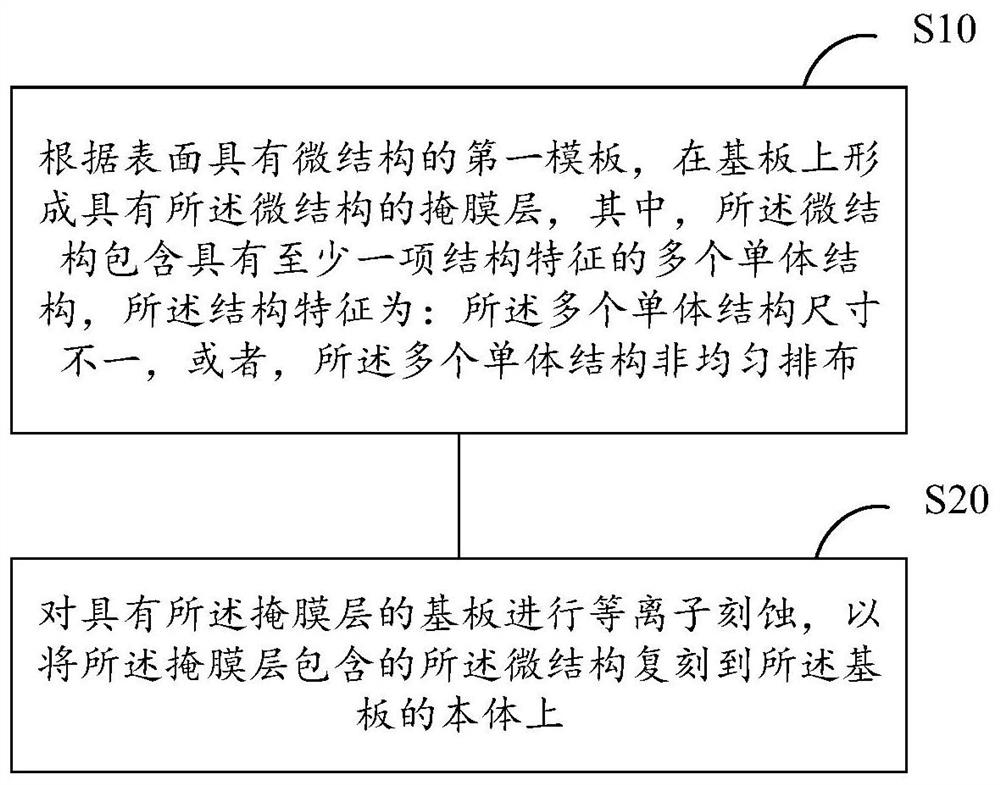

[0036] see figure 1 , figure 1 It is a flow chart of a method for generating a microstructure provided by an embodiment of the present application. In this embodiment, the method for generating a microstructure may include step S10 and step S20.

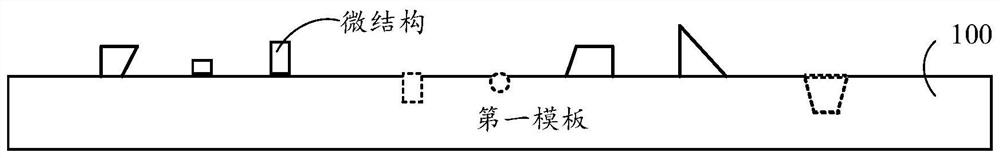

[0037] In order to ensure the anti-glare effect of the product with microstructure (anti-glare product), before step S10, a brief introduction is made to the first template with microstructure.

[0038] In this embodiment, the first template has a microstructure, and the microstructure here means: it includes a plurality of monomer structures having at least one structural feature. The structural features here indicate that the multiple monomer structures have different sizes, or that the multiple monomer structures are arranged non-uniformly.

[0039]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com