Interlaced yarn-like processing equipment for polypropylene fiber air-jet texturing yarns and using method thereof

A technology for processing equipment and air variable yarn, which is applied in the direction of processing textile material equipment configuration, processing textile material carrier, liquid/gas/steam removal by air jet method, etc., which can solve the problem of lack of cleaning and removal equipment, impact of doping, dust and impurities Regeneration quality and other issues, to achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

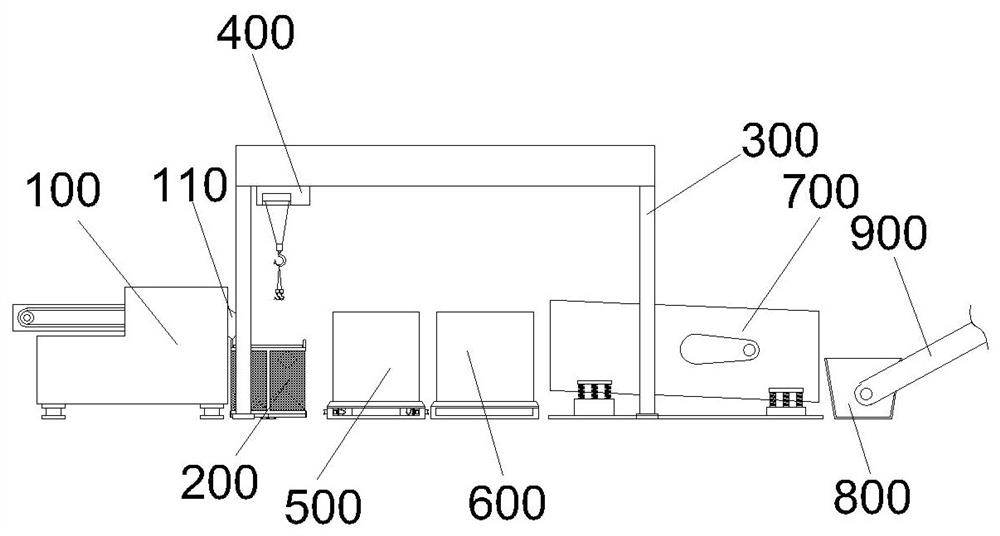

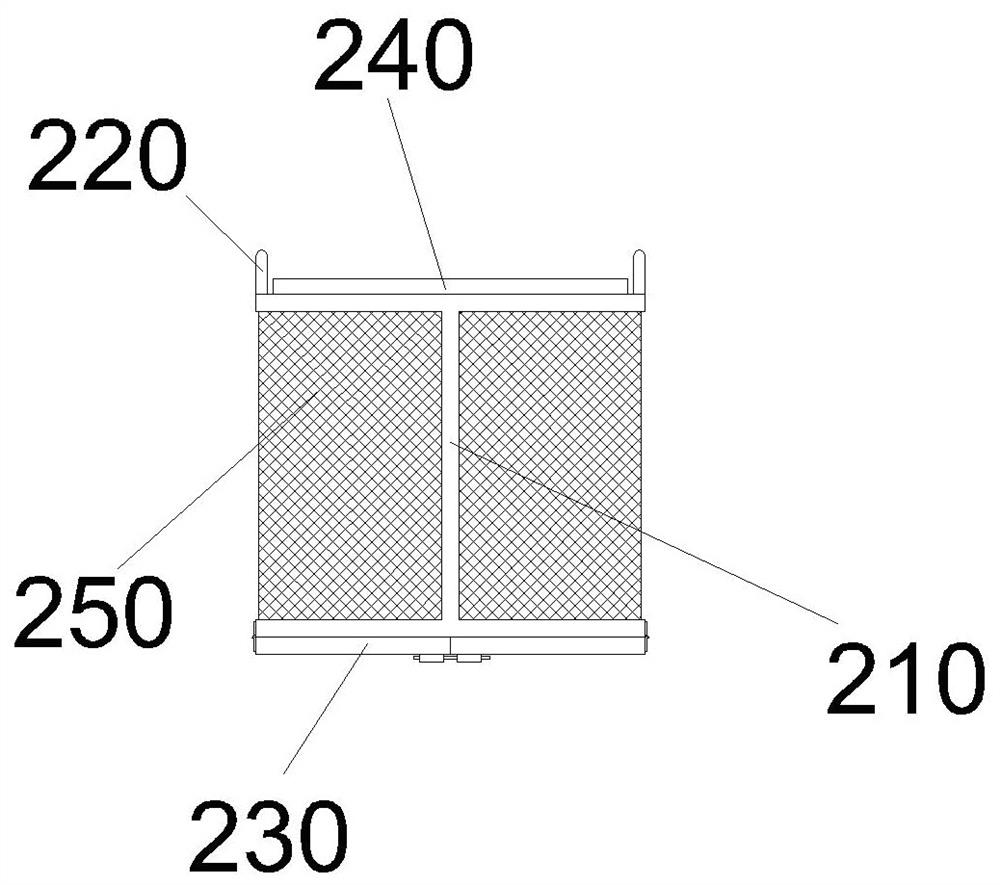

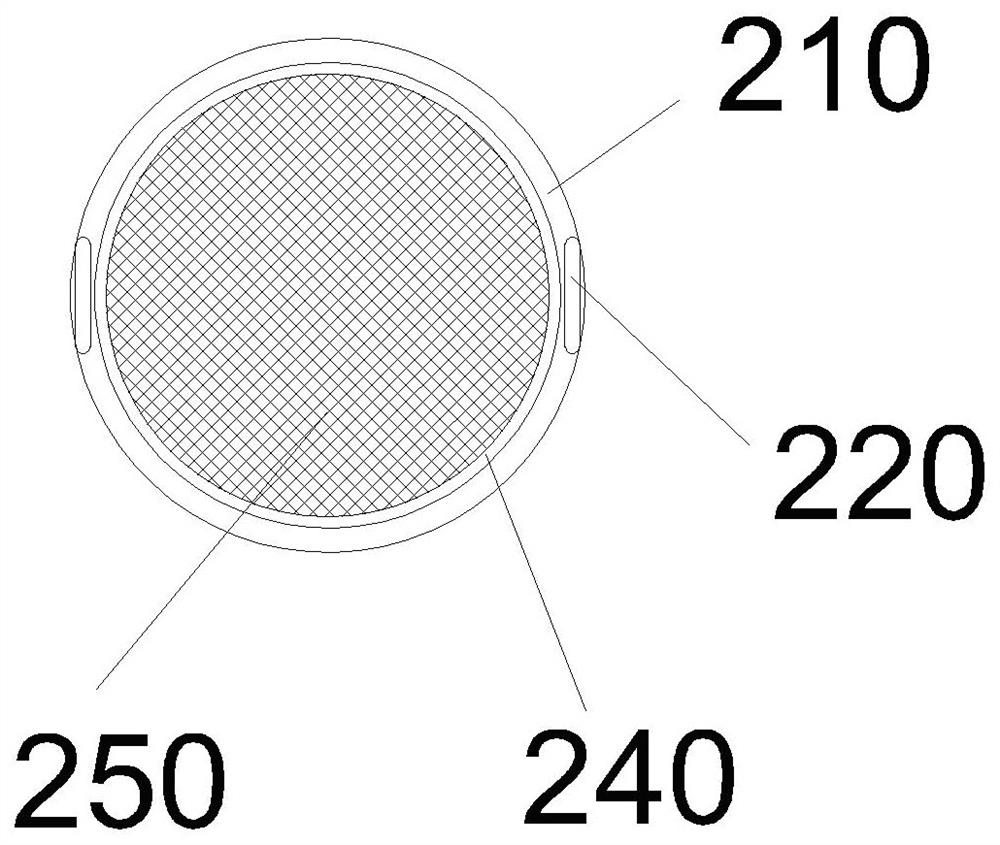

[0029] see Figure 1-Figure 6 , the present invention provides the following technical solutions: a kind of network yarn-like processing equipment for polypropylene air variable yarn and its use method, including a fiber cutter 100, and a discharge cylinder 110 is fixedly installed on the right outlet of the fiber cutter 100 , a collection device 200 is placed below the discharge cylinder 110, a hanger device 300 is provided on the right side of the fiber cutter 100, an electric hoist 400 is installed on the hanger device 300, and the hanger device 300 A cleaning device 500, a drying device 600 and a vibrating screen 700 are arranged on the inner side of the vibrating screen 700. A feeding trough 800 is provided under the right side of the vibrating screen 700. The inner cavity of the feeding trough 800 extends into a The input end of the lifting conveyor belt 900, and the output end of the lifting conveyor belt 900 is connected with the polypropylene fiber regeneration produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com