Gas injection and brine discharge device and method for salt-cavern gas storage

A gas storage and gas injection technology, which is applied in mining equipment, earthwork drilling, mining fluids, etc., can solve problems such as poor operability, unclear steps and parameters, and unclear parameters, so as to achieve accurate control and operability Strong, parameter-specific effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

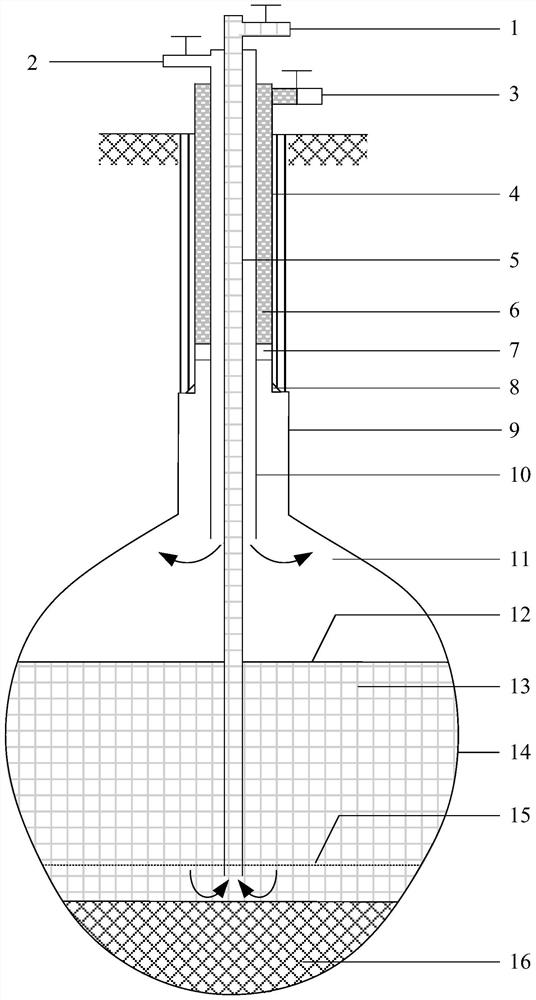

[0019] Such as figure 1 As shown, the gas injection and brine removal device for the salt cavern gas storage includes: casing 4, gas injection and brine removal inner pipe 5, and gas injection and brine removal outer pipe 10; the casing 4 is lowered from the ground to the underground until the casing shoe 8 position, the casing 4 is connected to the top of the well neck 9, and the bottom of the well neck 9 is connected to the top of the salt cavern 14; It is connected with the lower part of the casing 4 through the packer 7, and the annular space between the casing 4 on the upper part of the packer 7 and the gas injection and brine discharge outer pipe 10 is filled with the annular space protection fluid 6; the casing 4 and the gas injection and halogen discharge outer The top of the annulus between the pipes 10 is equipped with an annular protection liquid injection port gate valve 3; the gas injection and brine discharge inner pipe 5 is lowered into the lower part of the sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com