Self-sealing oil discharge valve and hydraulic sealing method of oil discharge valve

A technology of hydraulic sealing and oil discharge valve, which is applied in the direction of engine sealing, lifting valve, valve device, etc. It can solve the problems of large leakage and easy jamming of the valve core, etc., and achieves reduced jamming, good sealing effect, and processing easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

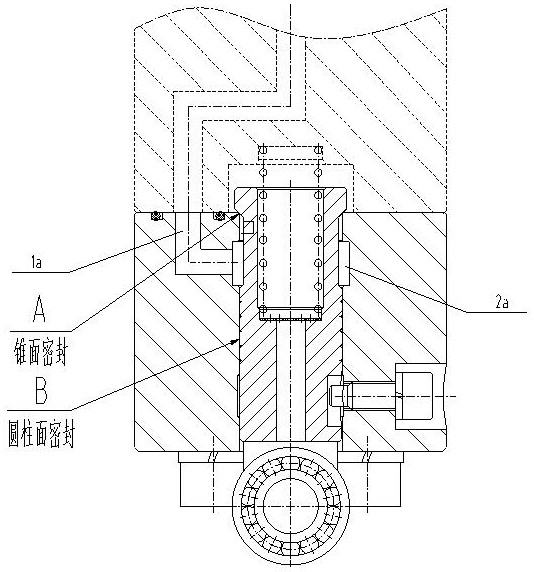

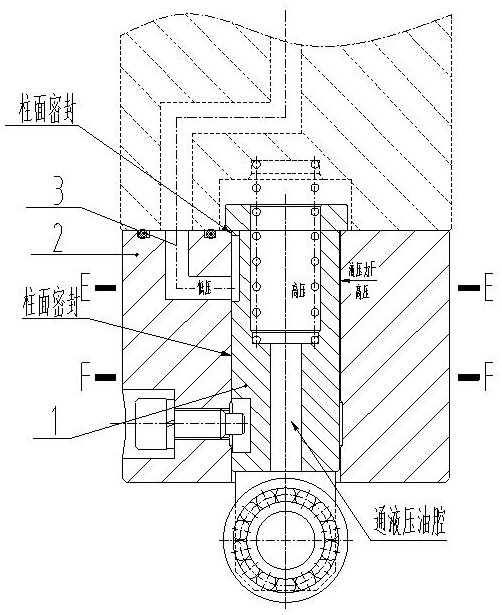

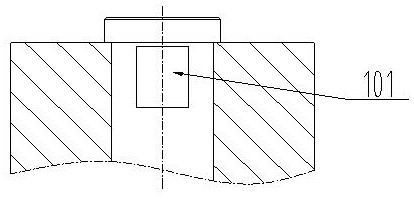

[0027] refer to figure 2 and image 3 As shown, a self-sealing oil discharge valve includes a spool and a valve body. The spool of the spool can slide along the spool hole in the valve body. A flange is provided on the end of the spool protruding from the spool hole. The flange is used to form a seal with the end face of the spool hole; the oil return hole in the valve body communicates with the spool hole, and the spool hole is a cylindrical hole; the spool is cylindrical, and the spool corresponds to the return hole. The position of the oil hole is provided with an overflow gap.

[0028] The overflow gap is a plane gap or a curved surface gap, and it is only necessary to ensure that part of the arc on the cylindrical surface of the valve column is removed. The chord length of the overcurrent notch refers to the chord length corresponding to the arc portion on the cylindrical surface of the valve post removed due to the processing of the overcurrent notch.

[0029] A sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com