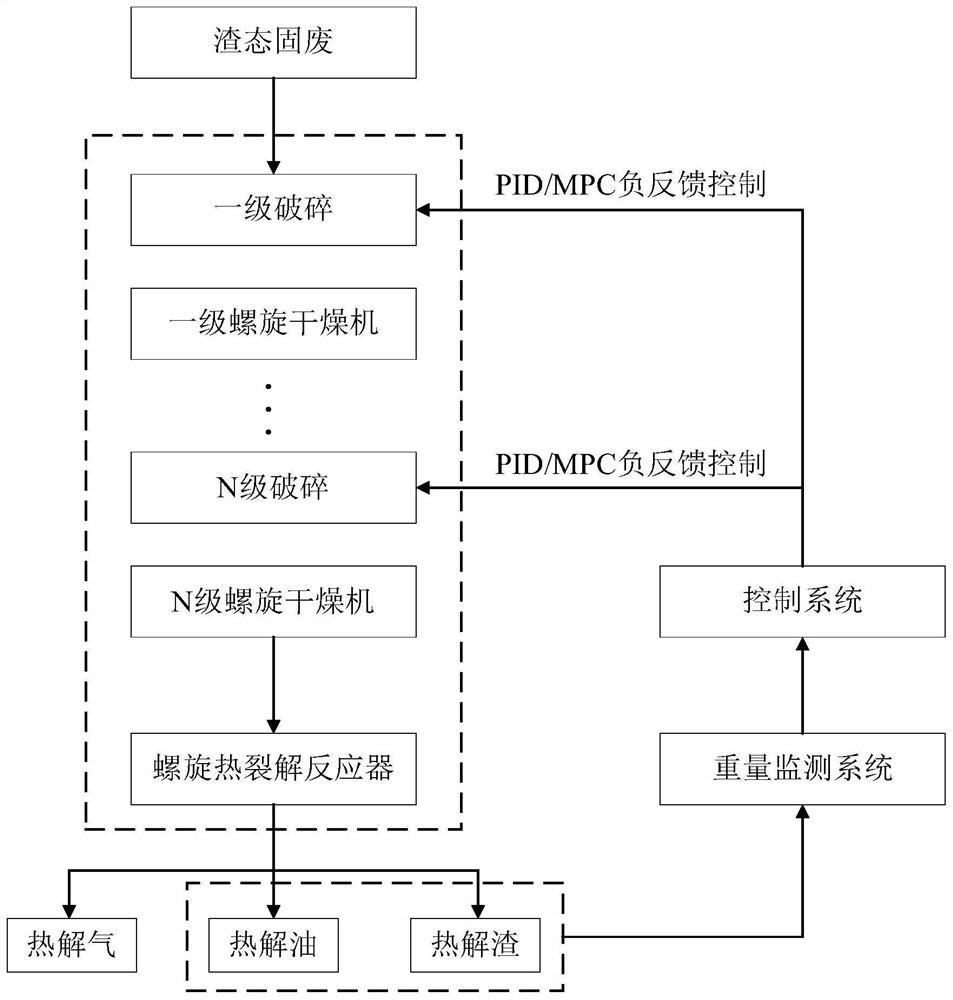

Multi-stage crushing intelligent treatment device and method for high moisture content slag state solid waste

A technology with high water content and treatment equipment, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of low intelligence, achieve good stability, flexible operation, and avoid thermal stress fatigue problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Taking the treatment of oil sludge with a water content of 56% as an example, it includes a two-stage crushing and drying unit and a pyrolysis reaction unit. When the pyrolysis temperature is 600°C and the dynamic control system of the device operates stably, the pyrolysis oil yield is 23%. , the yield of pyrolysis slag is 69%, and the yield of pyrolysis gas is 8%.

Embodiment 2

[0060] Taking the treatment of kitchen waste with a water content of 71% as an example, it includes a three-stage crushing and drying unit and a pyrolysis reaction unit. When the pyrolysis temperature is 600°C and the dynamic control system of the device operates stably, the pyrolysis oil yield 16%, pyrolysis slag yield 71%, pyrolysis gas yield 13%.

Embodiment 3

[0062] Taking the treatment of food waste with a water content of 60% as an example, it includes a two-stage crushing and drying unit and a pyrolysis reaction unit. When the pyrolysis temperature is 600°C and the dynamic control system of the device operates stably, the pyrolysis oil yield 29%, pyrolysis slag yield 57%, pyrolysis gas yield 14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com