Iron tower stress and vibration detection device

A vibration detection and iron tower technology, applied in the direction of measuring device, electric device, measuring force, etc., can solve the problems of increased installation cost, low measurement accuracy, poor anti-interference ability, etc., to achieve easy control, strong anti-interference ability, fast acting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

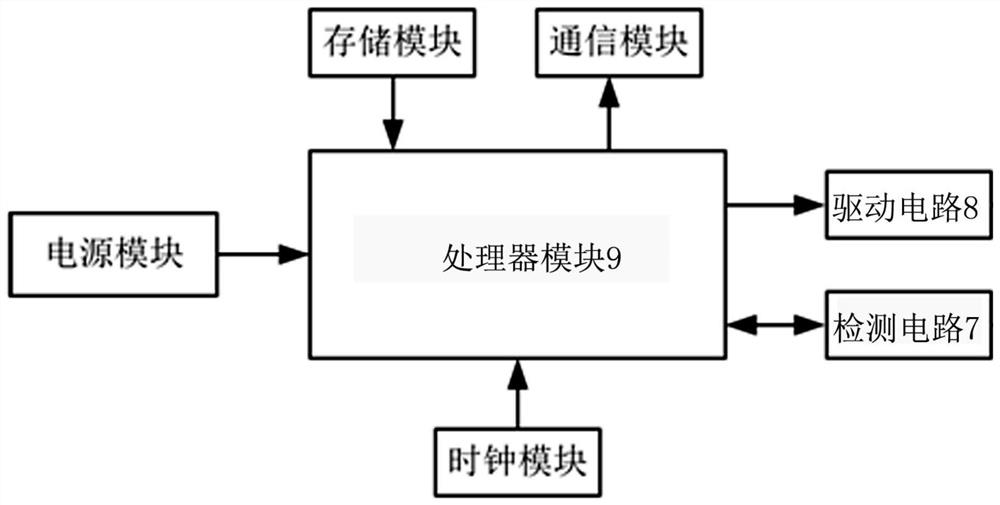

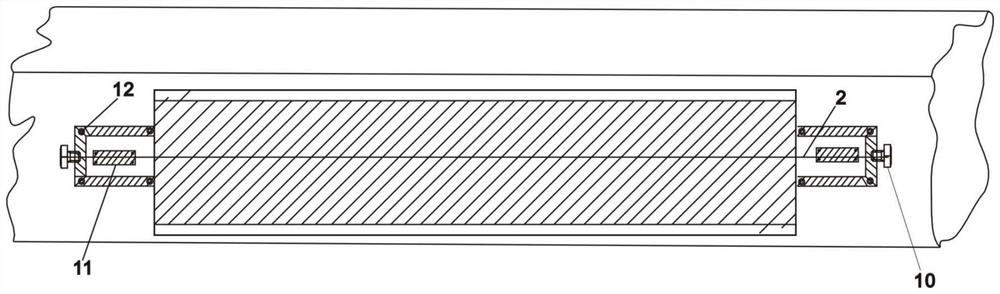

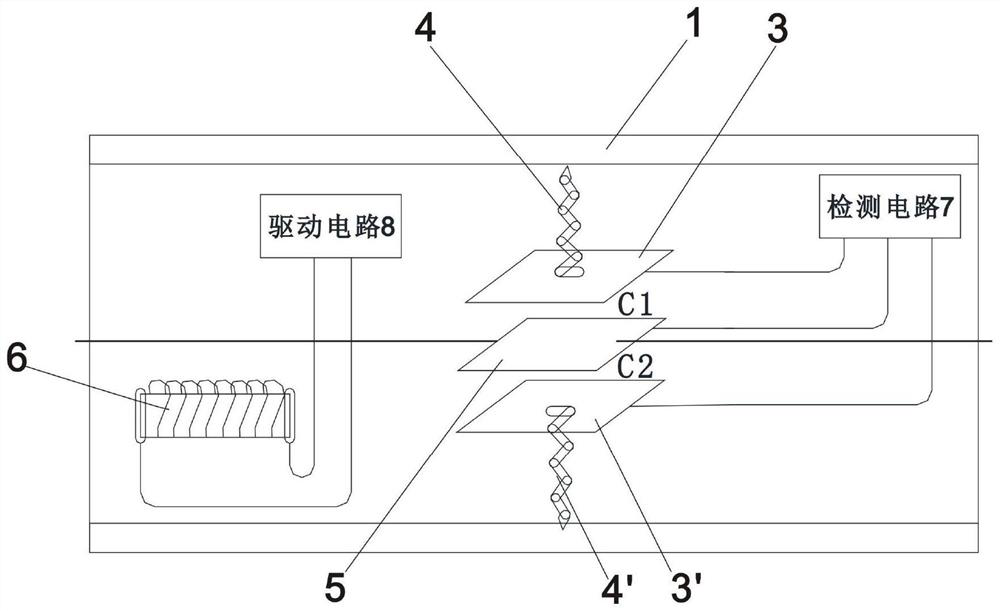

[0027] Such as figure 1 , image 3 As shown, the steel tower stress and vibration detection device includes a housing 1 with holes on both sides of the housing 1, and steel strings 2 pass through the housing 1 through the holes on both sides and are fixed to the iron tower.

[0028] The housing 1 is provided with an upper pole plate 3 and a lower pole plate 3', and the upper pole plate 3 and the lower pole plate 3' are respectively fixed inside the housing 1 by a first spring 4 and a second spring 4'. An intermediate plate 5 is arranged between the plate 3 and the lower plate 3', and the intermediate plate 5 is fixed on the steel string 2. The upper plate 3, the lower plate 3', and the middle plate 5 are parallel to each other, and the three The pole plate is connected with the detection circuit 7 .

[0029] The upper plate 3 and the middle plate 5 form a capacitance C 1 , the lower plate 3' and the middle plate 5 form a capacitance C 2 ;

[0030] The casing 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com