Wet sealing cover capable of improving dyeing quality

A technology of wetting and covering, applied in the preparation of test samples, etc., can solve problems such as the influence of experimental results, poor circulation effect, and insufficient heat uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

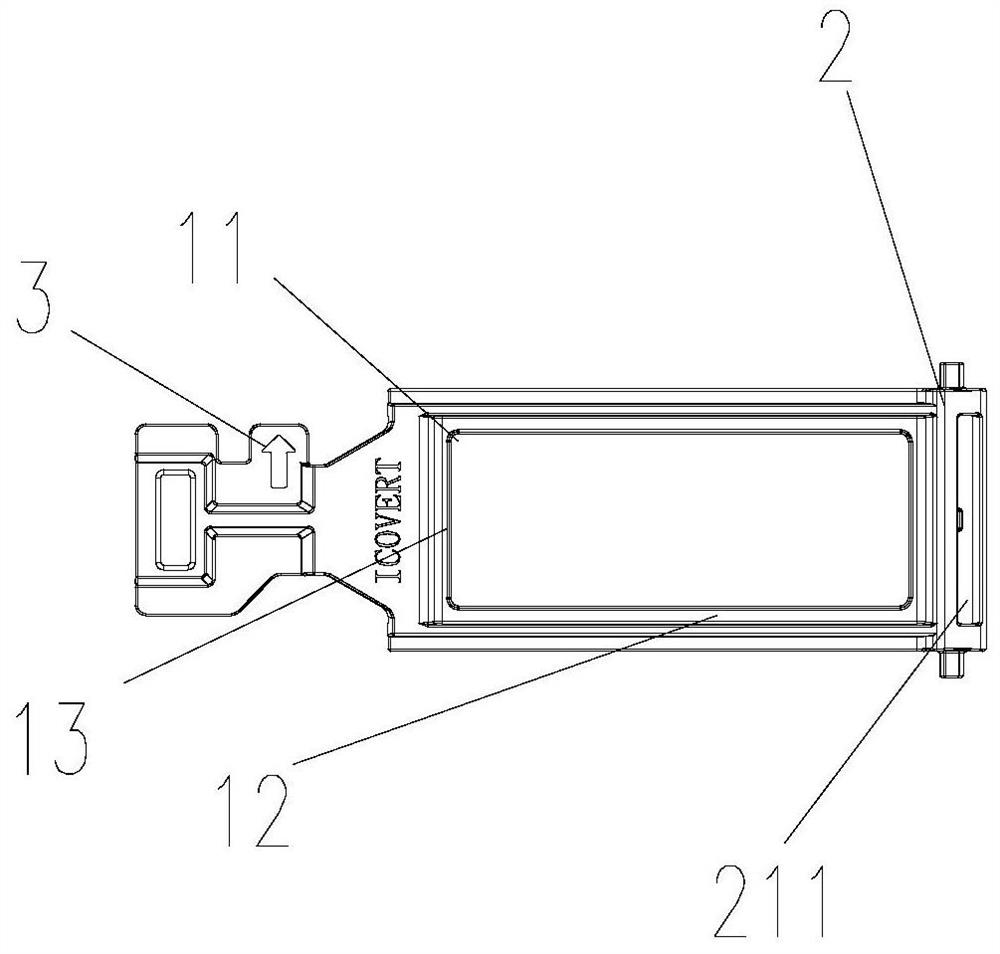

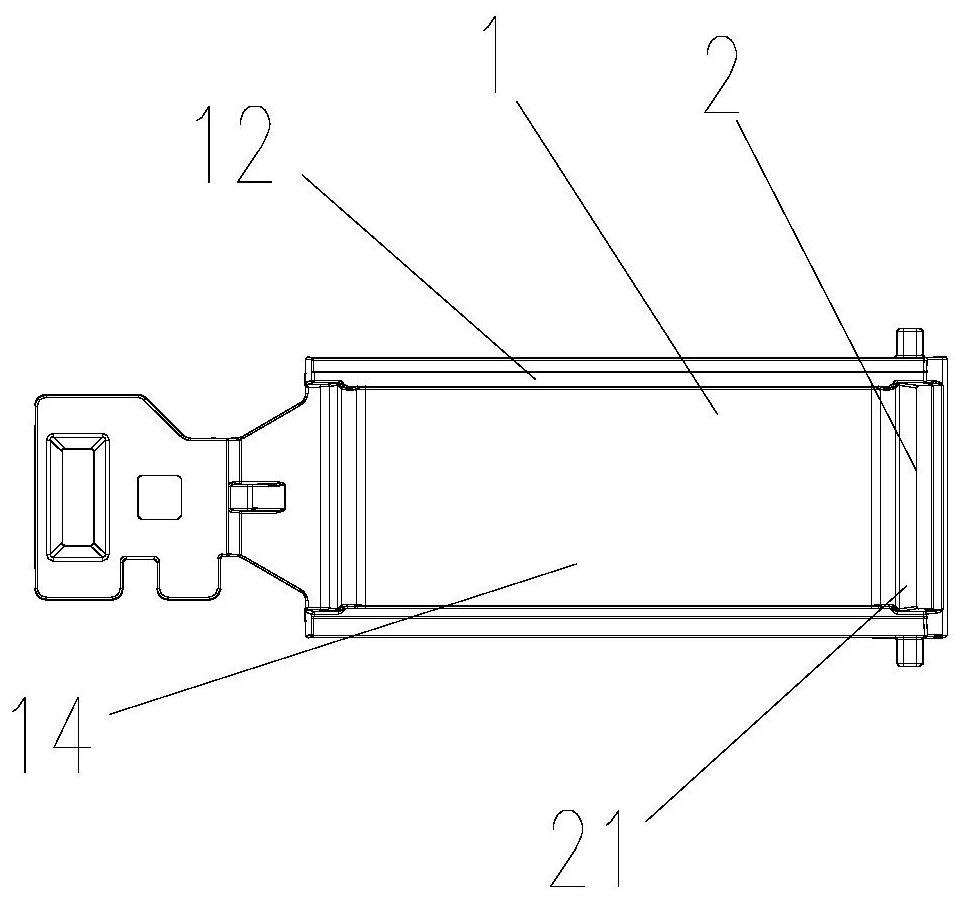

[0031] like figure 1 , figure 2 A wet-sealed cover for improving dyeing quality is shown, including a reaction area 1 for forming a reaction chamber, a liquid addition area 2 for adding liquid or storing liquid, and the liquid addition area 2 communicates with the reaction chamber, dripping The liquid entering the liquid feeding area 2 enters the reaction chamber of the reaction area 1 due to factors such as siphon.

[0032] The reaction zone 1 includes a reaction zone upper cover 11 , side support ribs 12 , and a reaction zone rear wall 13 , and the side support ribs 12 and the reaction zone rear wall 13 are fixed on the reaction zone upper cover 11 . There is a step difference between the side support rib 12, the rear wall 13 of the reaction zone and the closed reaction zone upper cover 11, and the step difference is 0.1mm-0.13mm. Therefore, when the slide is covered, the side support rib 12. The rear wall 13 of the reaction area is sealed with the slide, and the upper co...

Embodiment 2

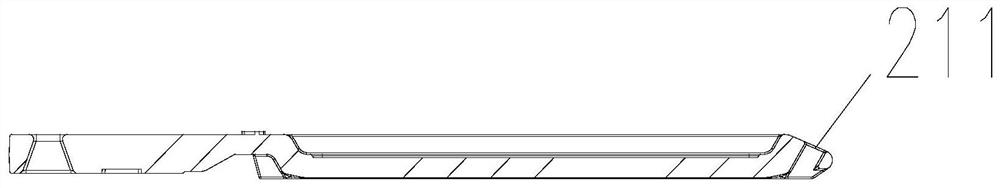

[0036] A wet-seal lid for improved dyeing quality as shown in Example 1, the only difference being that, as Figure 4 As shown, a liquid storage tank 212 is provided below the inclined liquid filling surface of the liquid filling port 211. The reaction chamber and the liquid storage tank 212 are respectively located on both sides of the liquid filling port 211, and the reaction chamber is located at the rear side. The liquid tank 212 is located at the front side, and the liquid in the liquid storage tank 212 can flow into the reaction chamber. By setting the liquid storage tank 212, it is ensured that excess liquid can be absorbed, and the liquid can be quickly entered into the reaction chamber, which ensures that the liquid is replenished in time during the heat recovery process, and that no gas enters the reaction chamber.

Embodiment 3

[0038] A wet-seal lid for improved dyeing quality as shown in Example 1, the only difference being that, as image 3 As shown, a liquid distributor 2111 is provided on the liquid filling slope of the liquid filling port 211, and the liquid distributor 2111 is integrated with the liquid filling slope, and one end thereof is connected to the liquid filling slope, and the height of the protrusion is 1mm -3㎜, the liquid dispenser 2111 has a liquid dispenser inclined surface, the width of the liquid dispenser inclined surface is smaller than the width of the liquid filling inclined surface, and the liquid dispenser inclined surface is trapezoidal, gradually widening from the top, and the width is 1cm-2cm, the angle range between the liquid dispenser 2111 and the liquid-filling inclined surface is 0°-10°, and the connection position between the liquid dispenser 2111 and the liquid-inclining surface is higher than the height of the bottom surface of the upper cover 11. By setting the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com