Method for evaluating micro-defect working stress of large casting and forging

A technology of working stress and casting and forging, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as distortion of calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

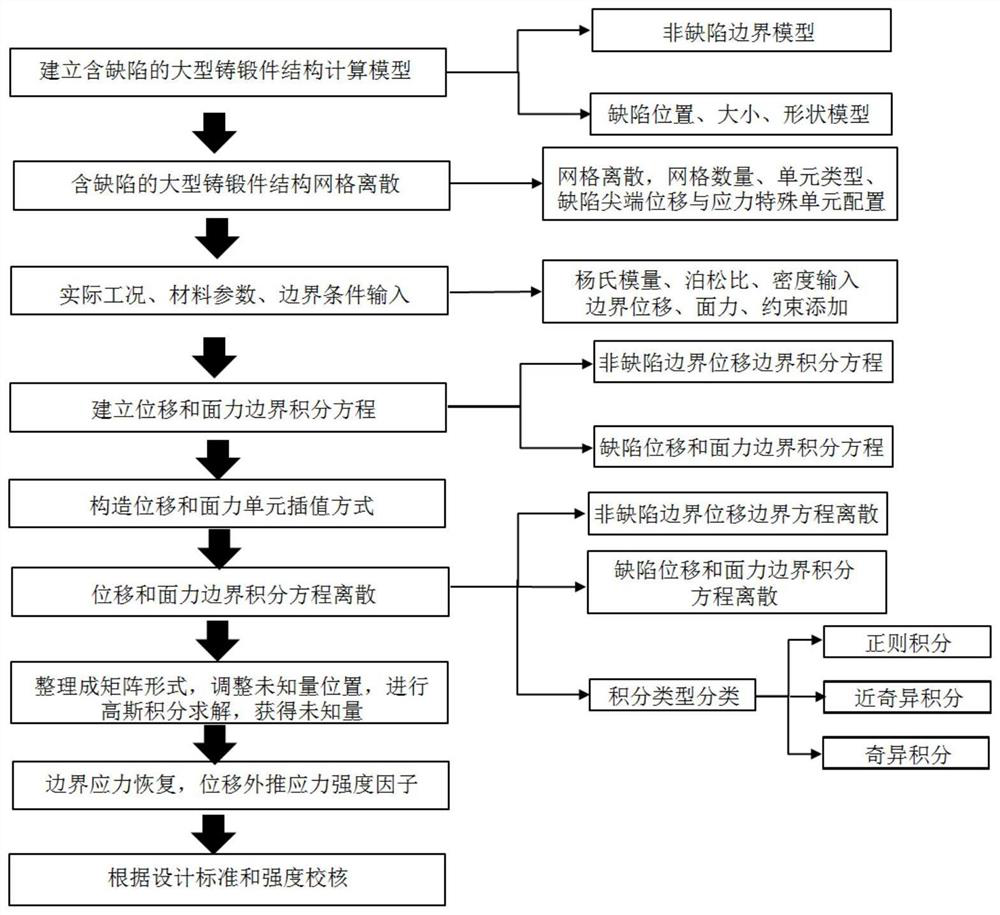

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

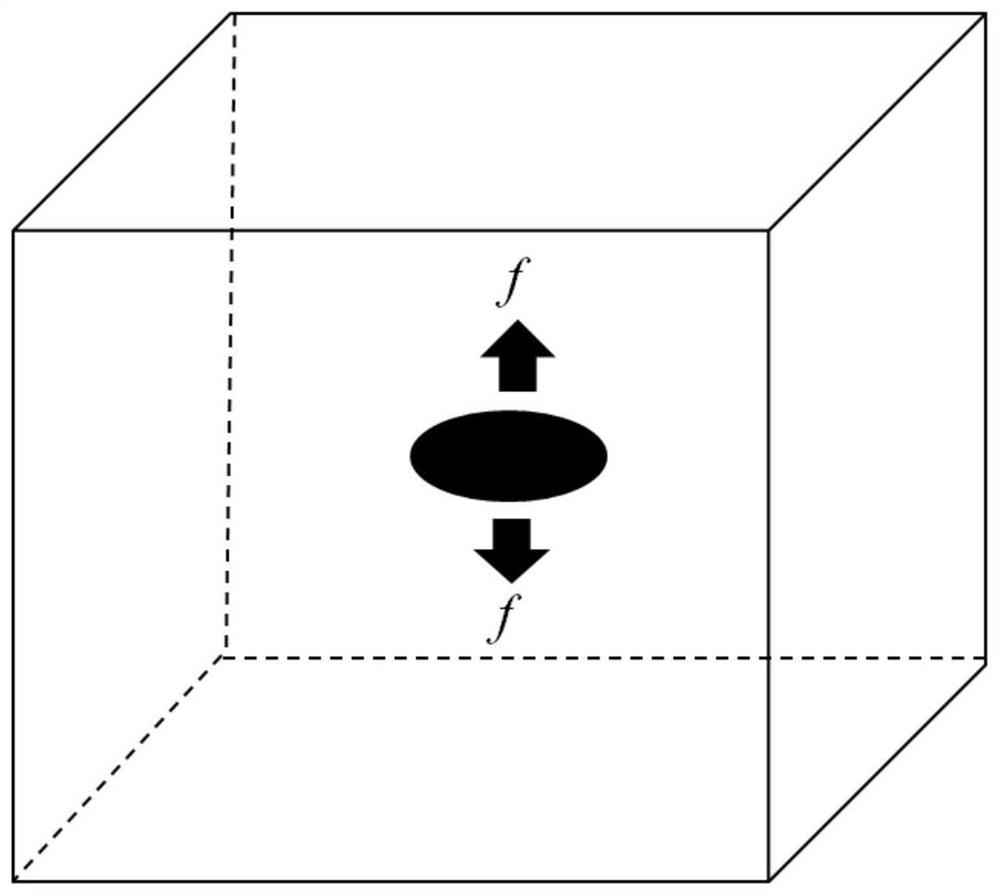

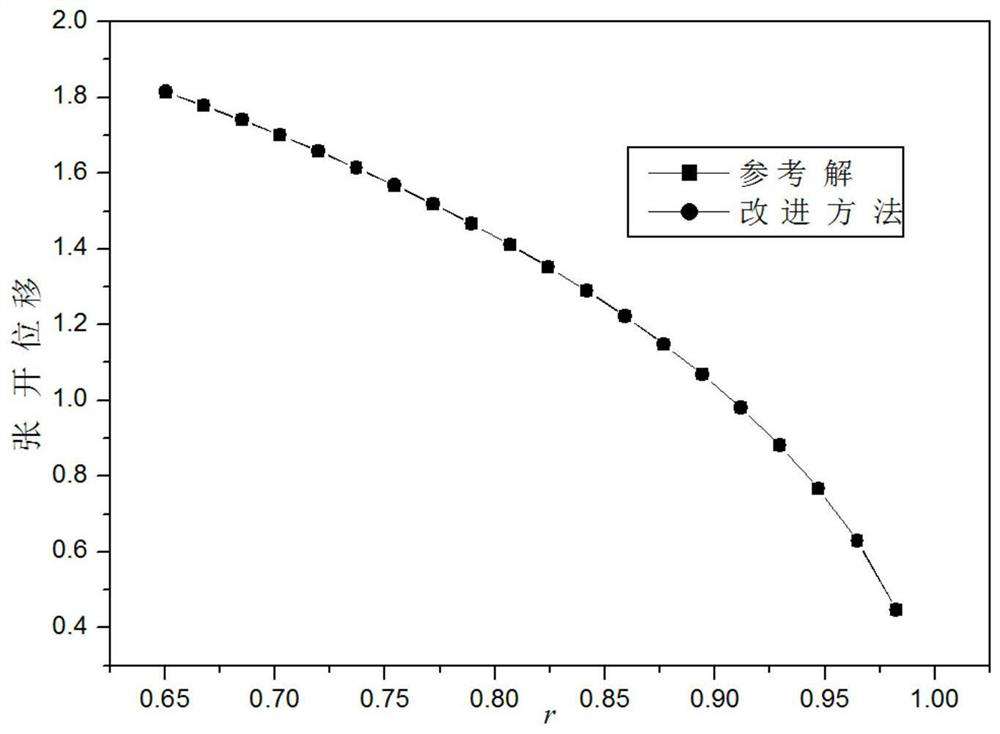

[0071] like figure 1 As shown, the present embodiment takes the microdisk (radius a=1.0) defect in a cube casting and forging (20×20×20) as an example:

[0072] Application step 1: Use ultrasonic detection technology on cube castings and forgings to obtain the size, position and nature of defects in the micro-discs (radius a=1.0) in the cube castings and forgings, and establish the micro-circles in the square castings and forgings (20×20×20) Calculation model of disk (radius a=1.0) defects, the body diagonal coordinate points of cube casting and forging are (-10, -10, -10) and (10,10,10), and the center of micro-disc is (0 ,0,0), with a radius of 1.0.

[0073] Application step 2: mesh discretization, the outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com