Welding workshop comprehensive scheduling method based on improved firework algorithm

A technology for welding workshop and fireworks algorithm, applied in the field of multi-objective optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

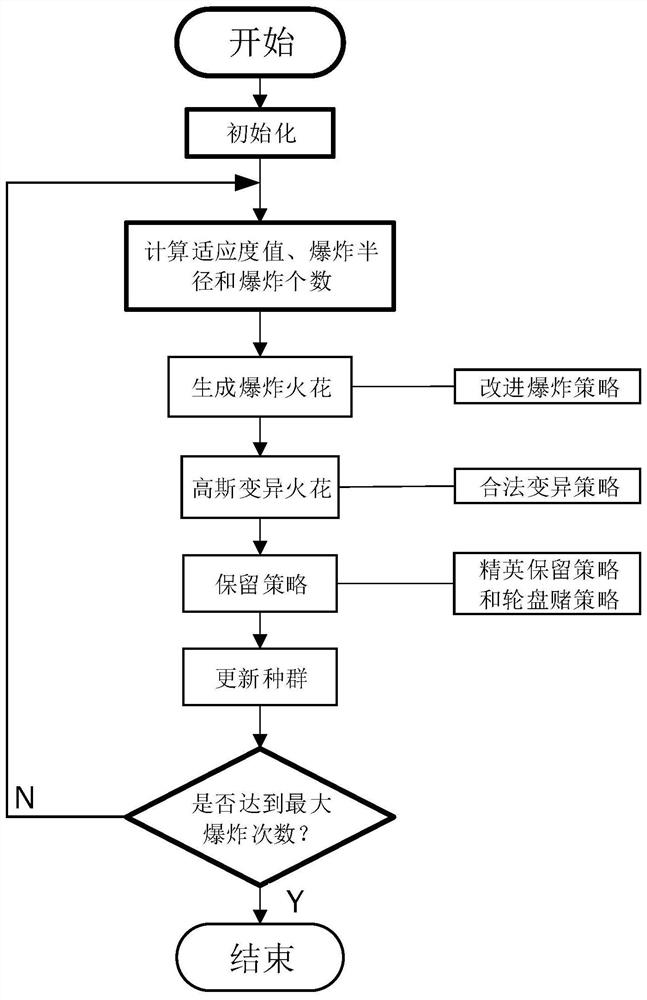

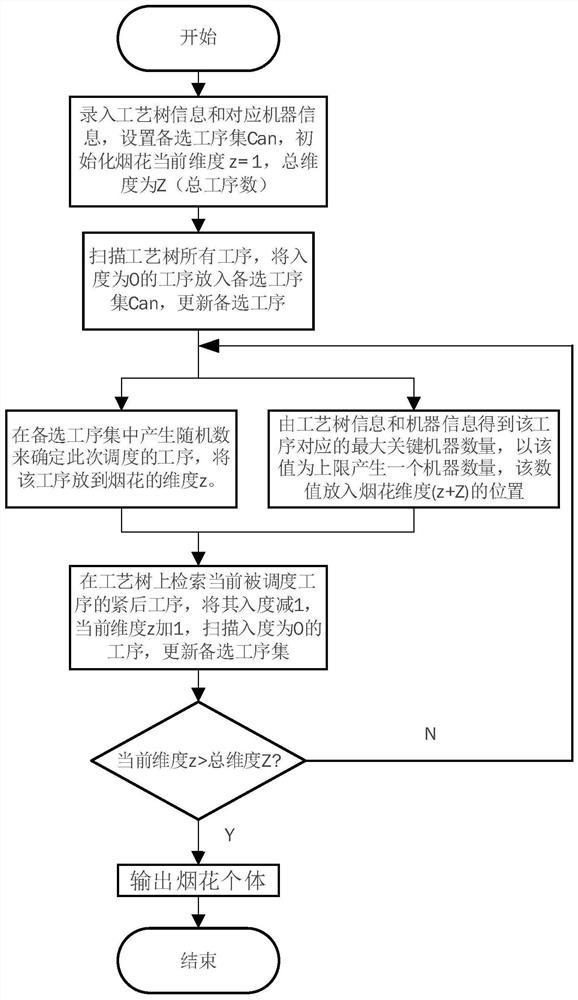

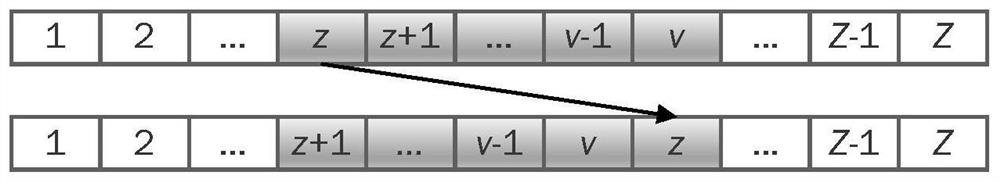

Method used

Image

Examples

Embodiment

[0087] A manufacturing company is preparing to produce complex welding product A, the process tree information is as follows Figure 5 As shown, it consists of 40 processes. The machine information is shown in Table 1, including 8 machine models, of which No. 1 to No. 5 machines are the main welding machines. The upper limit of the number of machines and the machine load factor can be read from the table. No. 8 is an auxiliary machine. The second column of machine type 1 represents the main welding machine, 0 represents the auxiliary machine, and the number represents the upper limit of the machine.

[0088] Table 1 machine information table

[0089]

[0090] Next, the genetic algorithm and the improved fireworks algorithm are used to schedule the product. Each algorithm is run independently 20 times, and the makespan and machine load of each test are taken, and the total target value is calculated. The comparison results are shown in Table 2:

[0091] Table 2 Algorithm c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com