Silk-screen printing machine

A technology for screen printing and printing procedures, applied in screen printing presses, printing presses, rotary presses, etc., to solve problems such as long intervention time and downtime, vulnerability to damage, and complex systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

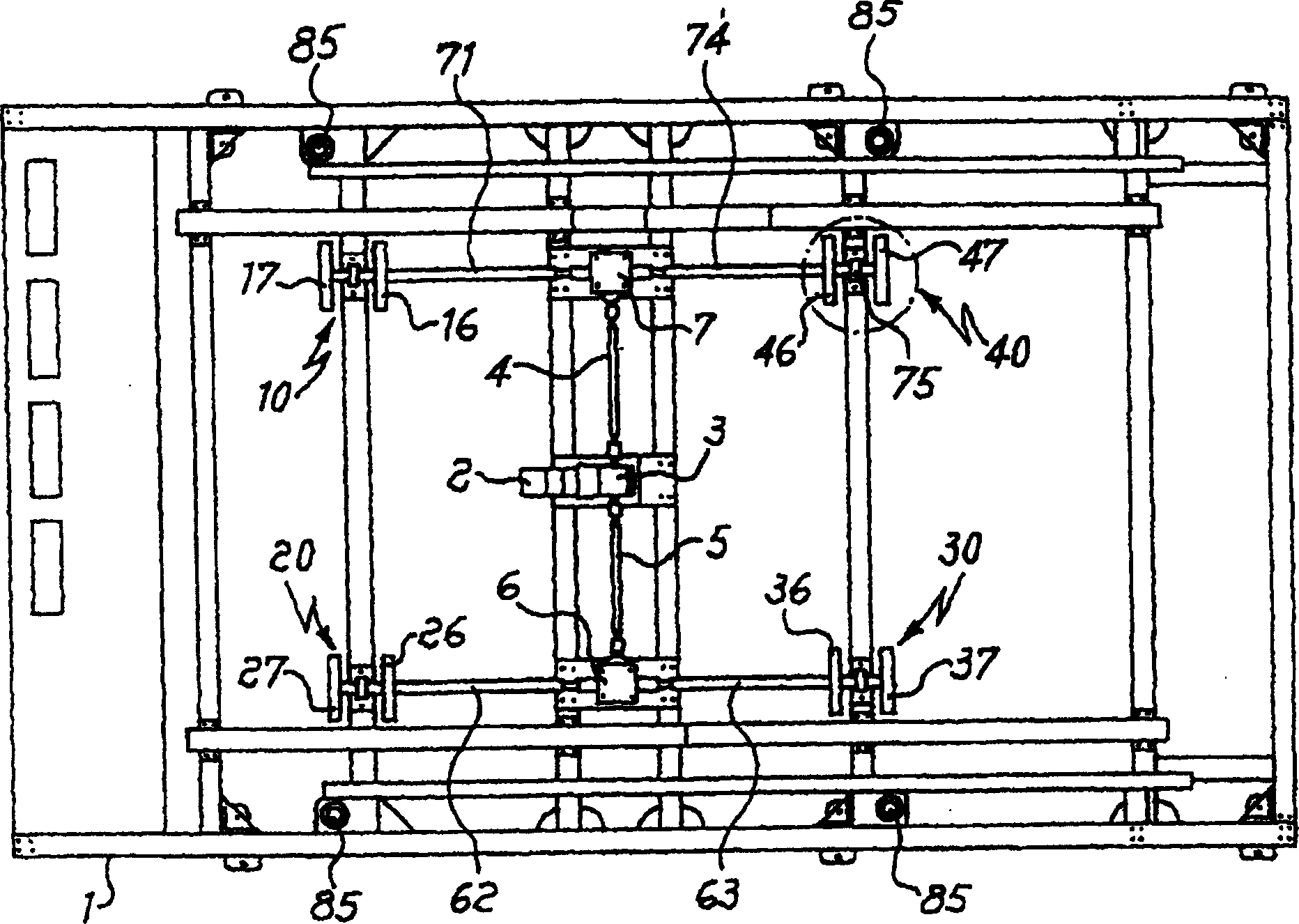

[0020] figure 1 Plan view representing the kinematic system of the fixed structure 1 and the frame (not shown in the figure for the sake of simplicity) of the screen printing machine for screen printing according to the present invention, the fixed structure is respectively connected to the frame connected to the support plane and connected to the printing The frame of the bridging device (not shown in the figure) is integrated into one piece.

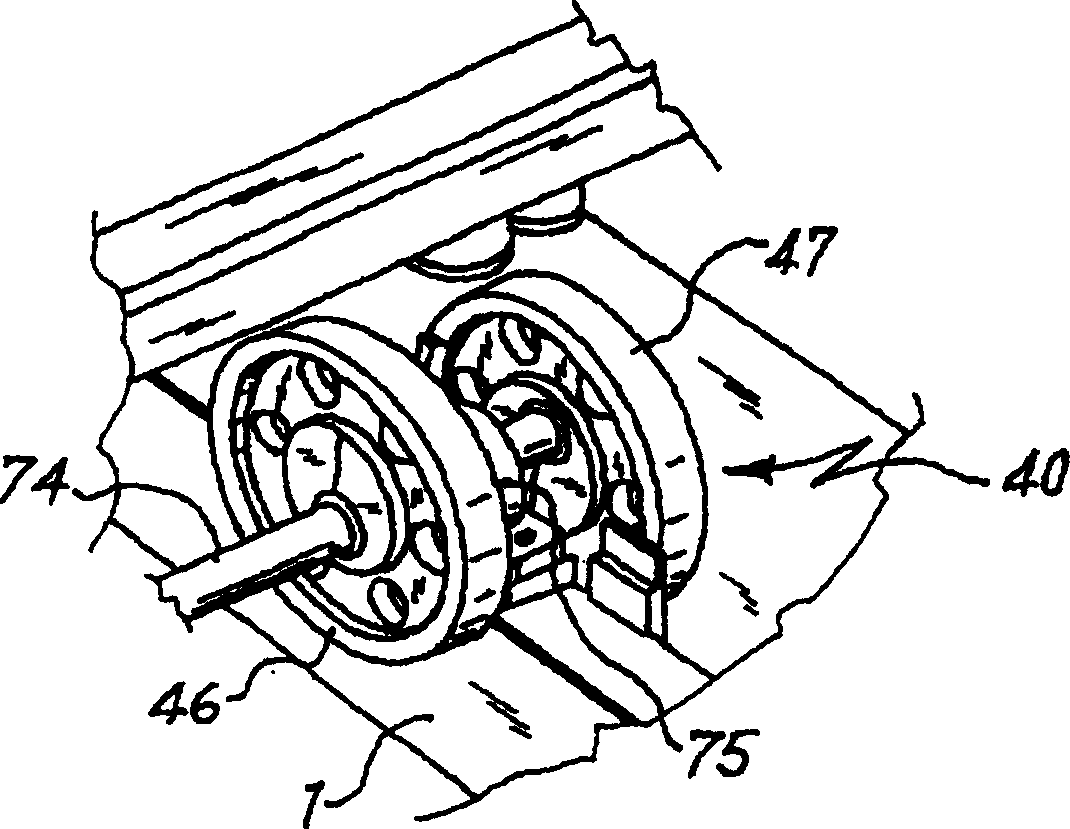

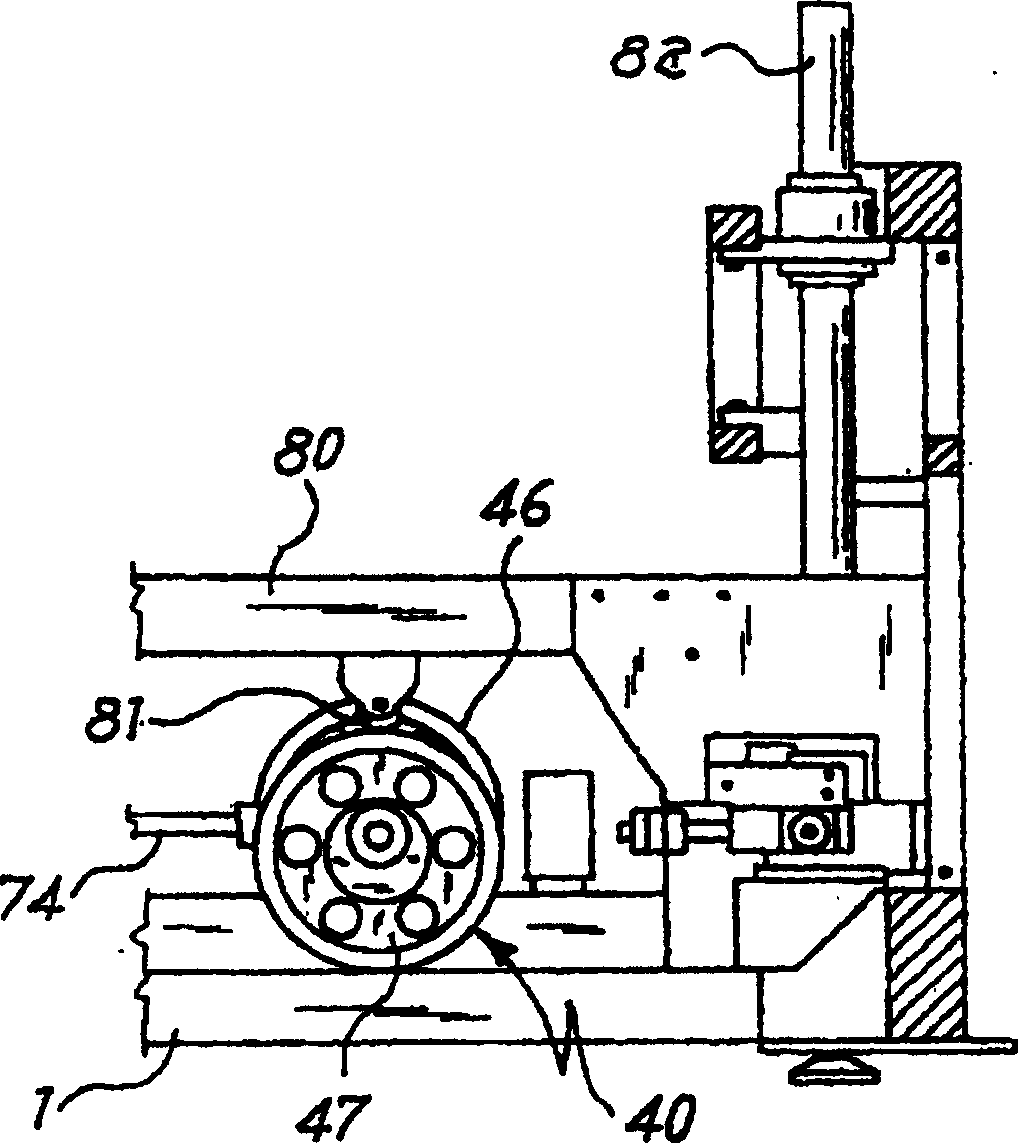

[0021] The kinematic system of the present invention is installed on the fixed structure 1, comprises four pairs of eccentric wheels 10, 20, 30 and 40, and these eccentric wheels will be combined below figure 2 A pair of eccentrics 40 shown in is described in detail.

[0022] The motion of the system is provided by an electric motor 2, which is transmitted from a first motion distribution box 3 to a pair of shafts 4 and 5, which are output from opposite sides of the distribution box 3, respectively. The shaft 5 is connected to a sec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap