Full-automatic pot handle assembling device

An assembly device and fully automatic technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low welding firmness, cumbersome heating process, and leakage of riveting positions, and achieve good welding results , convenient and fast brazing, high welding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is further described:

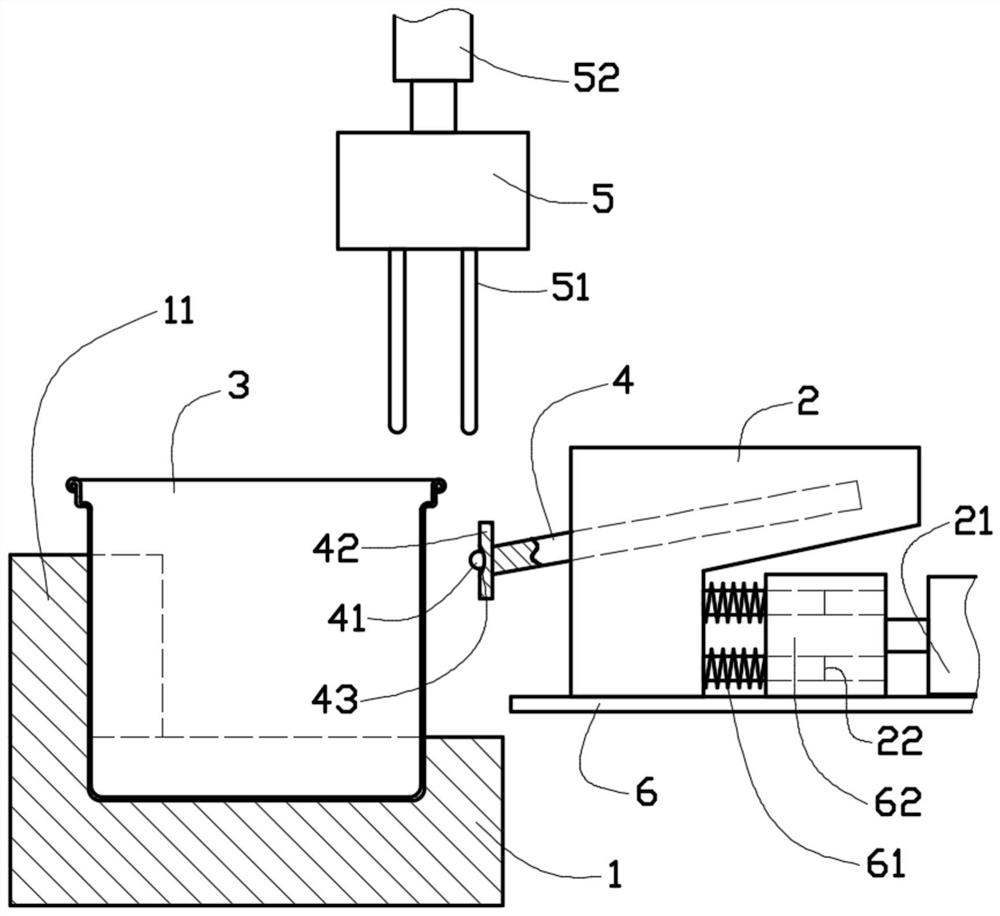

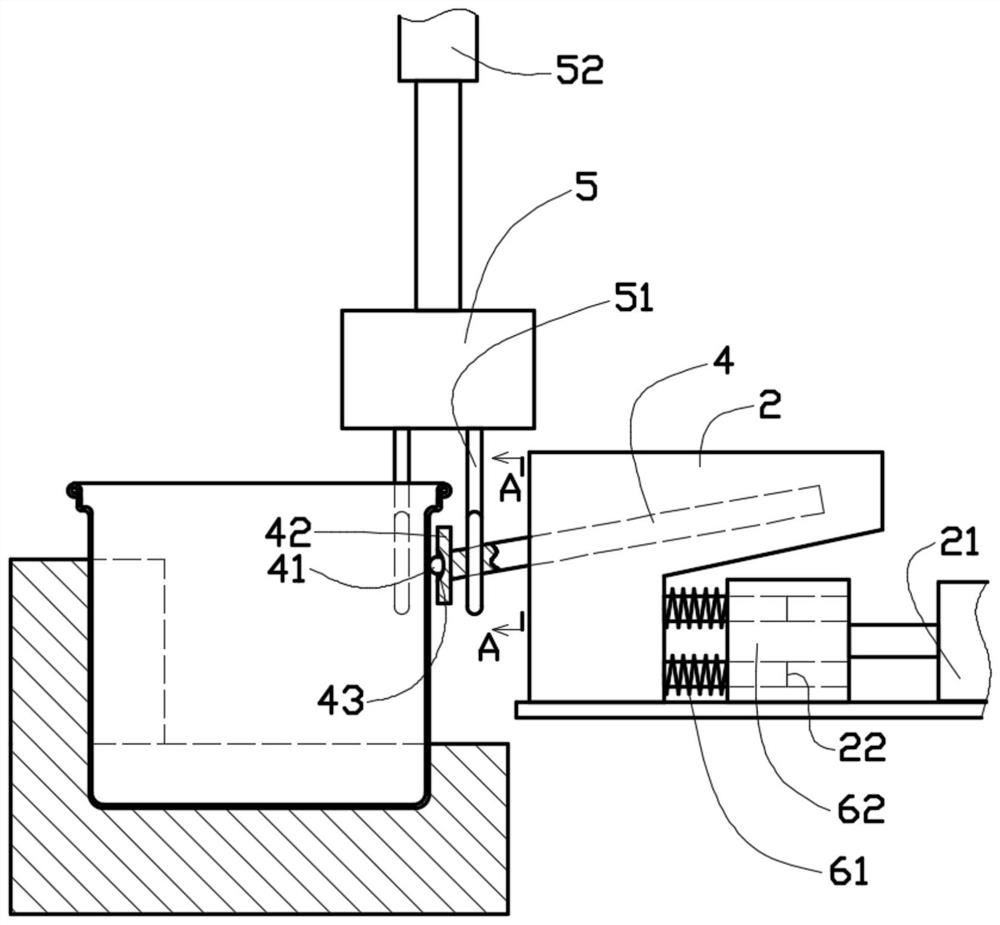

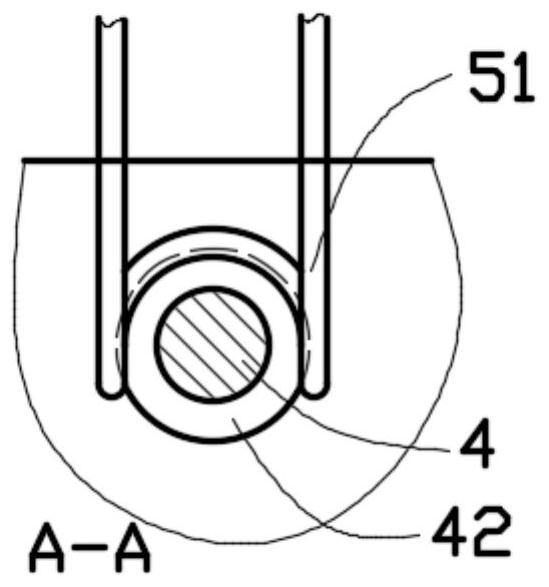

[0016] Such as figure 1 , figure 2 with image 3 As shown in the embodiment, the fully automatic pot handle assembly device includes a pot base 1 and a handle mold 2. The pot body 3 to be processed is placed on the pot base 1, and the pot base 1 limits the left and right sides of the pot body 3. Assembled, the handle part of the pot handle 4 is assembled in the handle mold 2, and the specific structure of the mold 2 is specifically designed according to the handle 4. During assembling, the welding position of the handle 4 of the pot stretches out toward the position of the pot body 3 on the right, and the connection position of the handle 4 of the pot is facing the position to be welded of the pot body 3. The rear portion of the handle mold 2 is equipped with a push module 21 that can push the handle mold 2 together with the pot handle 4 left and right. The position to be welded of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com