Welding device used for hydraulic cylinder

A welding device and hydraulic cylinder technology, which is applied in the field of hydraulic cylinder welding, can solve the problems of uneven rotation speed and poor welding quality of welders, and achieve the effects of being easy to deal with emergencies, improving stability, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

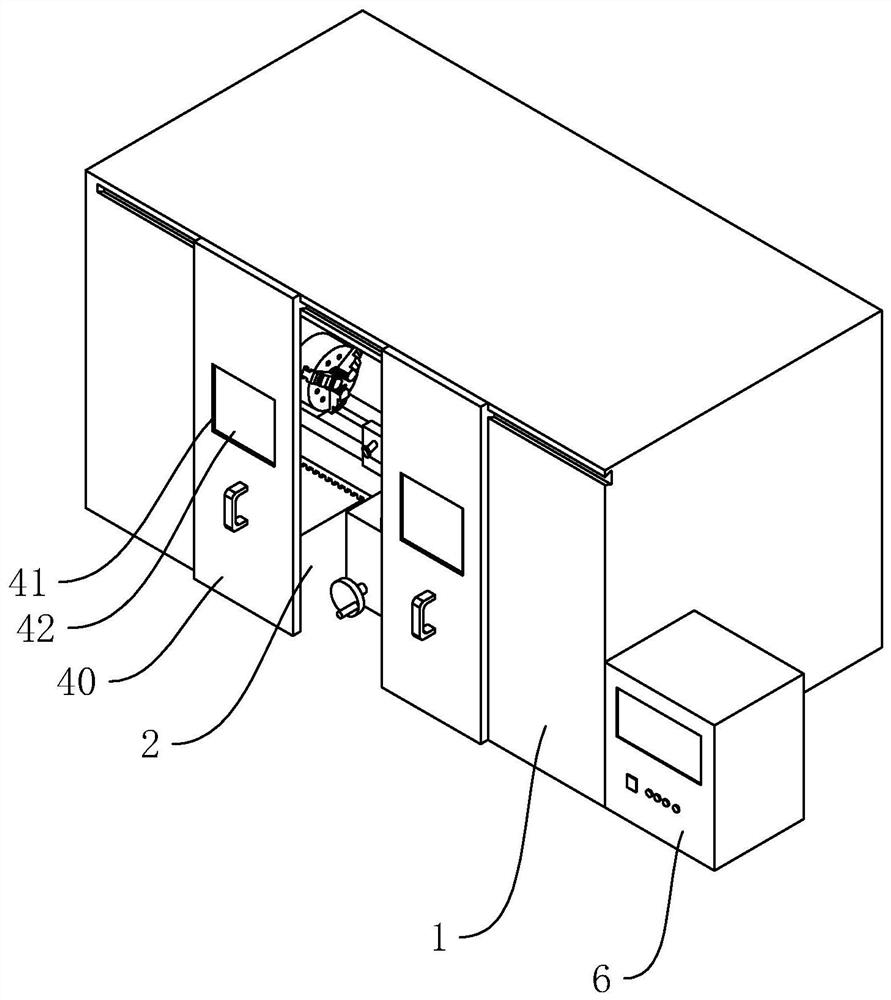

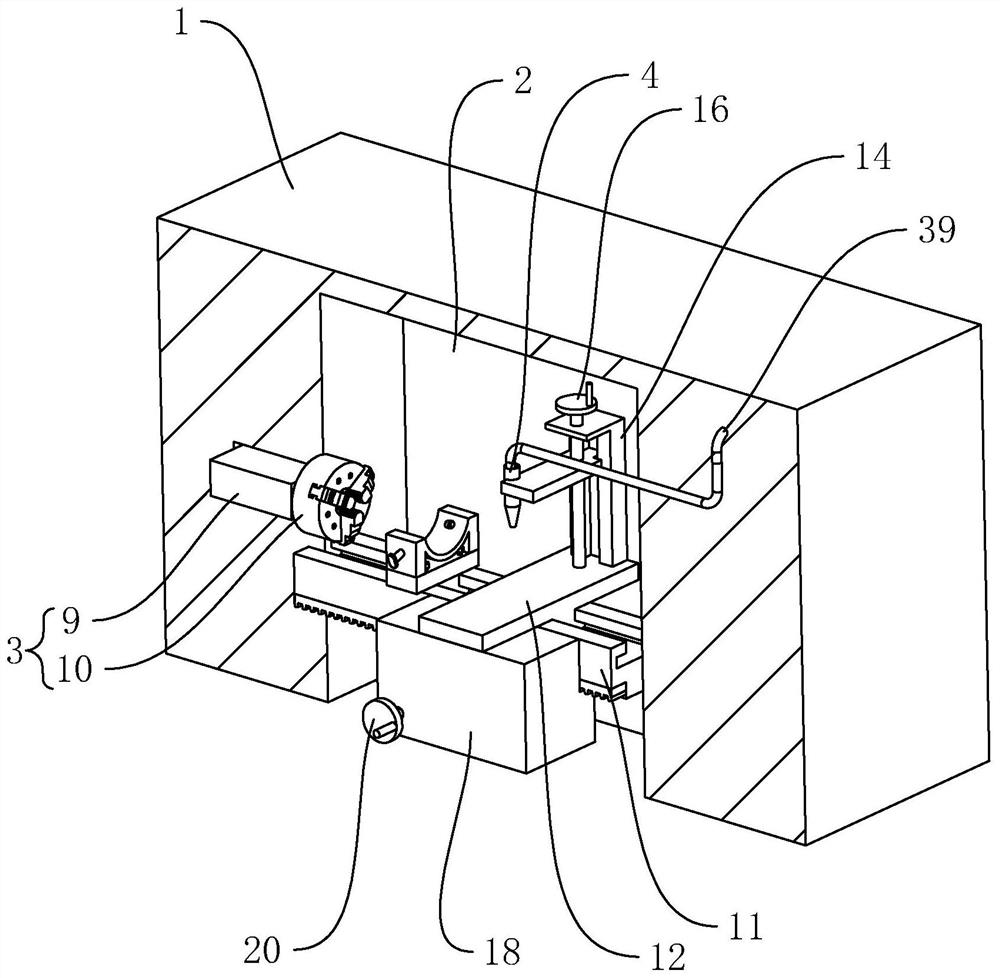

[0036] The following is attached Figure 1-6 The application is described in further detail.

[0037] The embodiment of the present application discloses a welding device for a hydraulic cylinder.

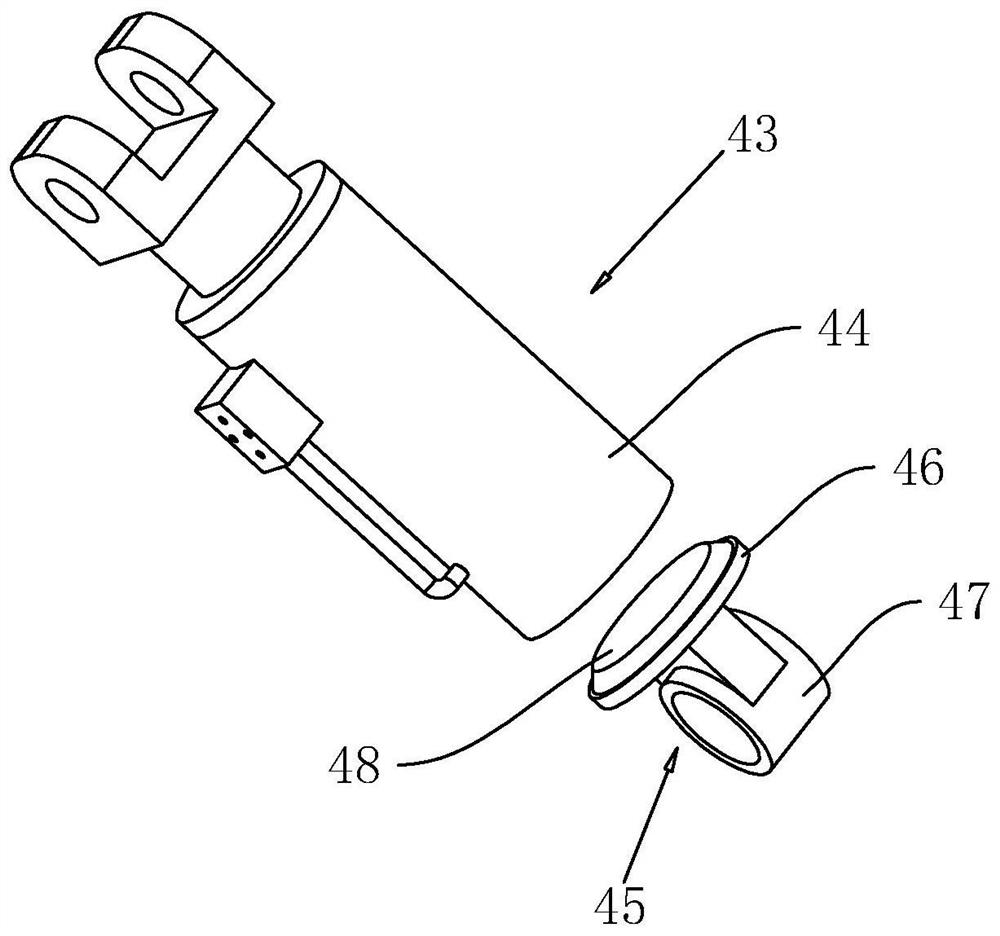

[0038] refer to figure 1 , the cylinder block 43 of the known hydraulic cylinder includes a shell 44 and a base 45, the shell 44 is a cylindrical metal shell, the material of the shell 44 is mainly No. 45 steel, and an inner chamfer is provided on the inner wall of one end of the shell 44, The base 45 includes a bottom plate 46 and a connecting sleeve 47, the connecting sleeve 47 is integrally formed on one side of the bottom plate 46, and the end of the connecting plate 17 away from the connecting sleeve 47 is integrally formed with a round table 48, and the round table 48 is embedded in the end of the shell 44 with inner chamfering In the inner cavity, the round platform 48 is in interference fit with the shell 44 , and the end of the bottom plate 46 away from the connecting sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com