Variable-rigidity air spring and rigidity regulation and control method thereof

An air spring and variable stiffness technology, applied in the direction of spring, spring/shock absorber, spring/shock absorber design characteristics, etc., can solve problems such as difficult to predict deformation process, unpredictable change process, and inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

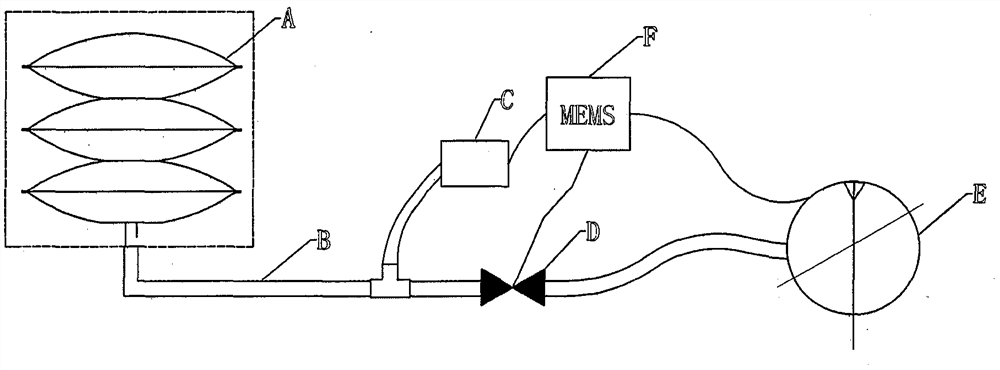

[0083] Figure 5 In order to implement the air spring air circuit and control system of the case, the air spring body (A), the internal pressure measurement module (C) of the air spring, the miniature solenoid valve (D), and the air pressure adjustable air pump (E) are connected through the hose (B) ) into an air circuit, and the gas pressure measurement module (C) inside the air spring, the miniature solenoid valve (D) and the air pressure adjustable air pump (E) are connected with the MEMS main control unit as the peripheral hardware system of the control system.

[0084] The working principle of the air spring and its control system is:

[0085] When the air spring bears the axial load, the gas inside the air spring body (A) is compressed, the volume v of the air spring body (A) decreases, the height h decreases, the internal gas pressure p increases, and the stiffness increases. The air spring body (A) ) is at any position, its internal gas pressure p is collected in real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com