Electric-hydraulic proportion regulation and control system for hydraulic machine

A proportional adjustment and control system technology, which is applied in the field of hydraulic presses, can solve the problems that the hydraulic press control system cannot provide variable stamping speed and variable blank holder force control, etc., and achieve the effect of enhanced adjustment, enhanced speed and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific structure of the present invention and its implementation will be further described below by referring to the accompanying drawings through examples.

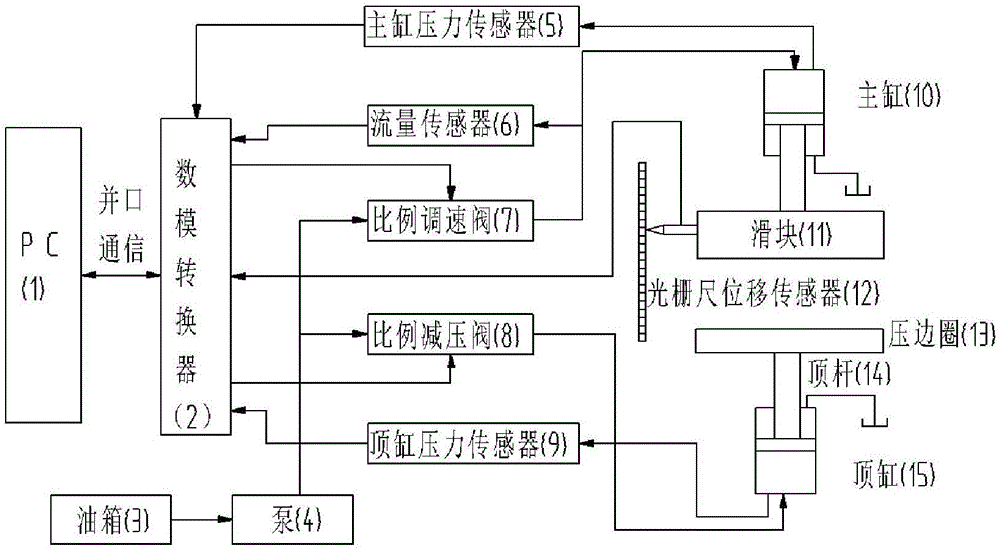

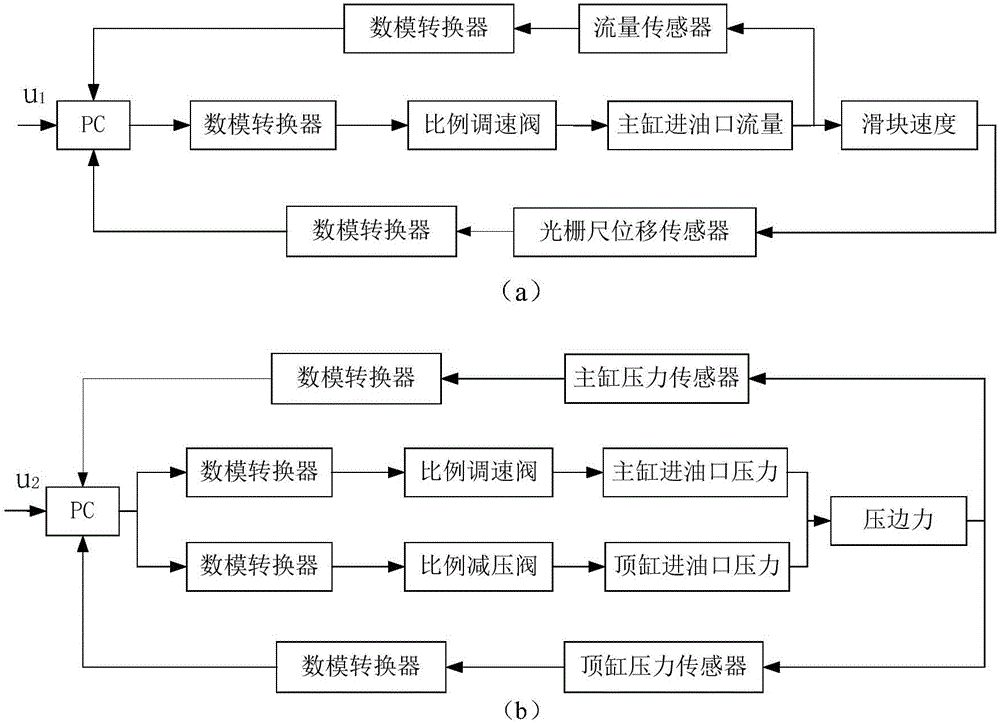

[0027] Such as figure 1 As shown, a hydraulic electro-hydraulic proportional adjustment control system, said system includes: PC1, digital-to-analog converter 2, fuel tank 3, pump 4, master cylinder pressure sensor 5, flow sensor 6, proportional speed control valve 7, proportional reducer Pressure valve 8, jacking cylinder pressure sensor 9, master cylinder 10, slider 11, grating scale displacement sensor 12, blank holder 13, ejector rod 14, jacking cylinder 15; PC1 communicates with digital-to-analog converter 2 via parallel port, The data information is bidirectionally transmitted; the adjustment command of the PC is transmitted to the proportional speed regulating valve 7 and the proportional pressure reducing valve 8 through the digital-to-analog converter 2 in the form of electrical signals, and then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com