Cold water phase transformation machine assisted energy tower heat pump system

An energy tower and heating system technology, applied in the energy field, can solve the problems of high heating energy consumption and reduced heating capacity at night, and achieve the effect of reducing operating energy consumption and ensuring heating capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

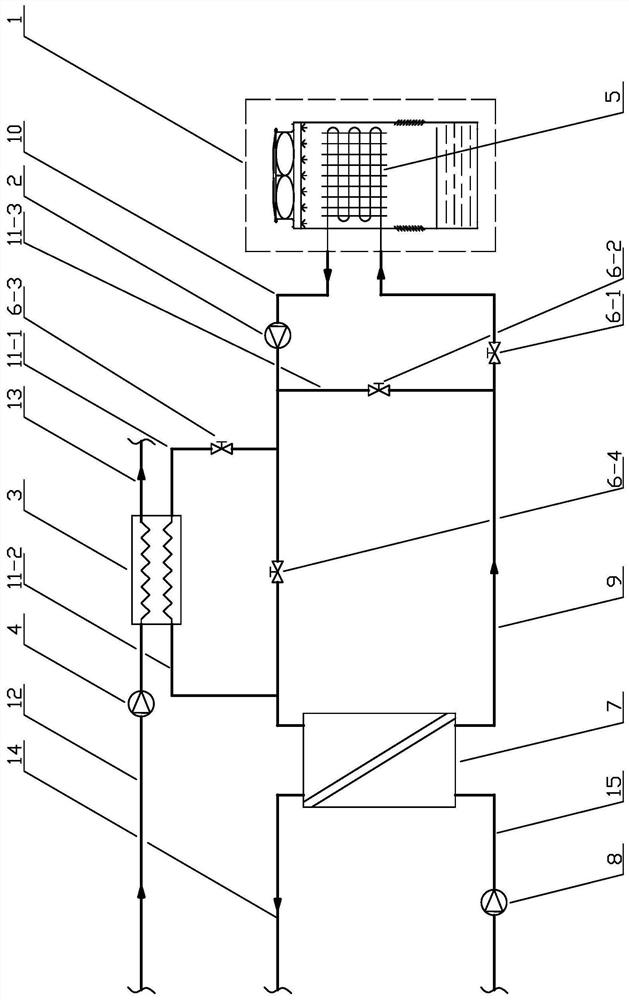

[0019] Specific implementation mode one, such as figure 1 As shown, a cold water phase change machine auxiliary energy tower heating system in this embodiment is composed of a closed energy tower 1, an antifreeze circulation pump 2, a cold water phase change machine 3, a cold water pump 4, and a solenoid valve 6-1 , Solenoid valve 2 6-2, Solenoid valve 3 6-3, Solenoid valve 4 6-4, Heat pump unit 7, Terminal circulation pump 8, Antifreeze liquid supply main pipe 9, Antifreeze liquid return main pipe 10, Branch pipe 11 -1, branch pipe two 11-2, branch pipe three 11-3, cold water phase change machine water supply pipe 12, cold water phase change machine drain pipe 13, end water supply pipe 14 and end return water pipe 15, the antifreeze liquid supply is dry One end of the pipe 9 is connected with the closed energy tower 1, and the other end is connected with the heat pump unit 7; the solenoid valve 16-1 is arranged on the antifreeze liquid supply main pipe 9; the antifreeze liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com