Motor and speed reducer fatigue test bench

A fatigue test and reducer technology, which is applied in motor generator test, machine/structural component test, mechanical component test, etc. It can solve the problems of large error, inability to meet the needs of use, low detection accuracy, etc., and achieve response speed. Fast, improve test efficiency, high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

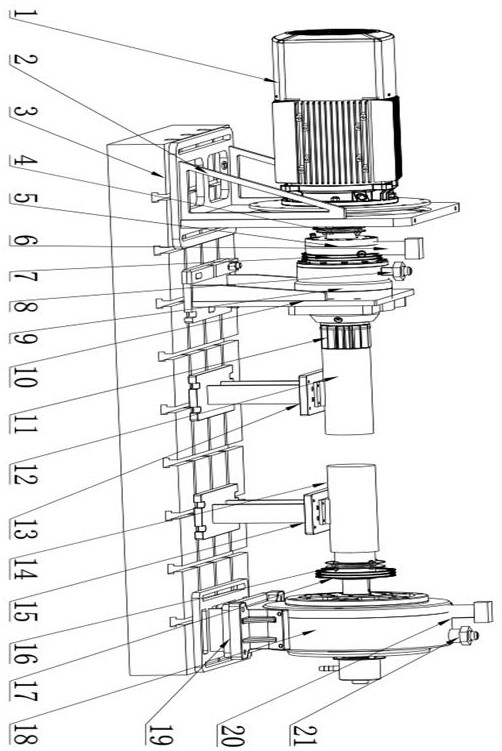

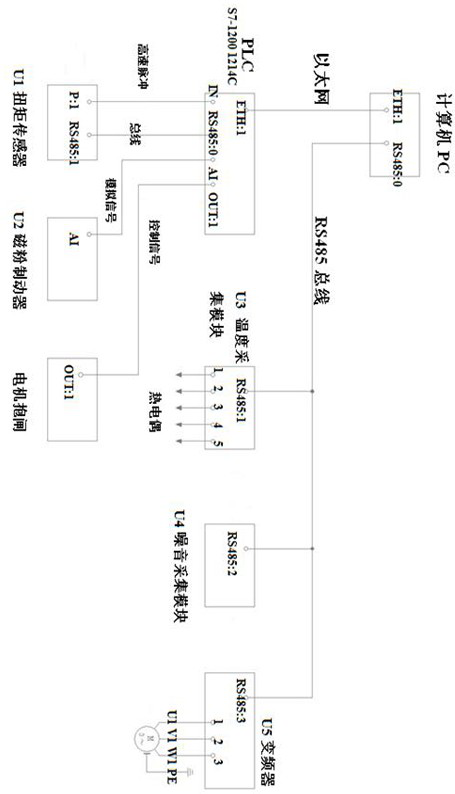

[0027] As shown in the accompanying drawings: a motor and reducer fatigue test bench, including a cast iron platform 3, and a first unit and a second unit respectively located at both ends of the cast iron platform 3, the first unit includes a first drive motor 1 and a reducer 9, the first drive motor 1 is connected to the reducer 9 through the first coupling 5, the reducer 9 is connected to the first torque sensor 12 through the second coupling 11, and the shaft of the reducer 9 is provided with a brake function The first magnetic powder ring 4; the first driving motor 1, the speed reducer 9, and the first torque sensor 12 are respectively installed on the cast iron platform 3 by the first motor support 2, the speed reducer support 10, and the first torque sensor support 13; the first motor The support 2, the reducer support 10, and the first torque sensor support 13 are all fixed on the cast iron platform 3 by bolts, which is convenient to improve the fixing effect and the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com