10kV high-voltage switch cabinet isolation baffle plate operating tool

A technology for high-voltage switchgear and isolation baffles, which is applied in the direction of switchgear guards/protection devices, switchgear, and switchgear parts, which can solve the problems of high risk of electric shock of baffles and improve the scope of use and application Range, effect for easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

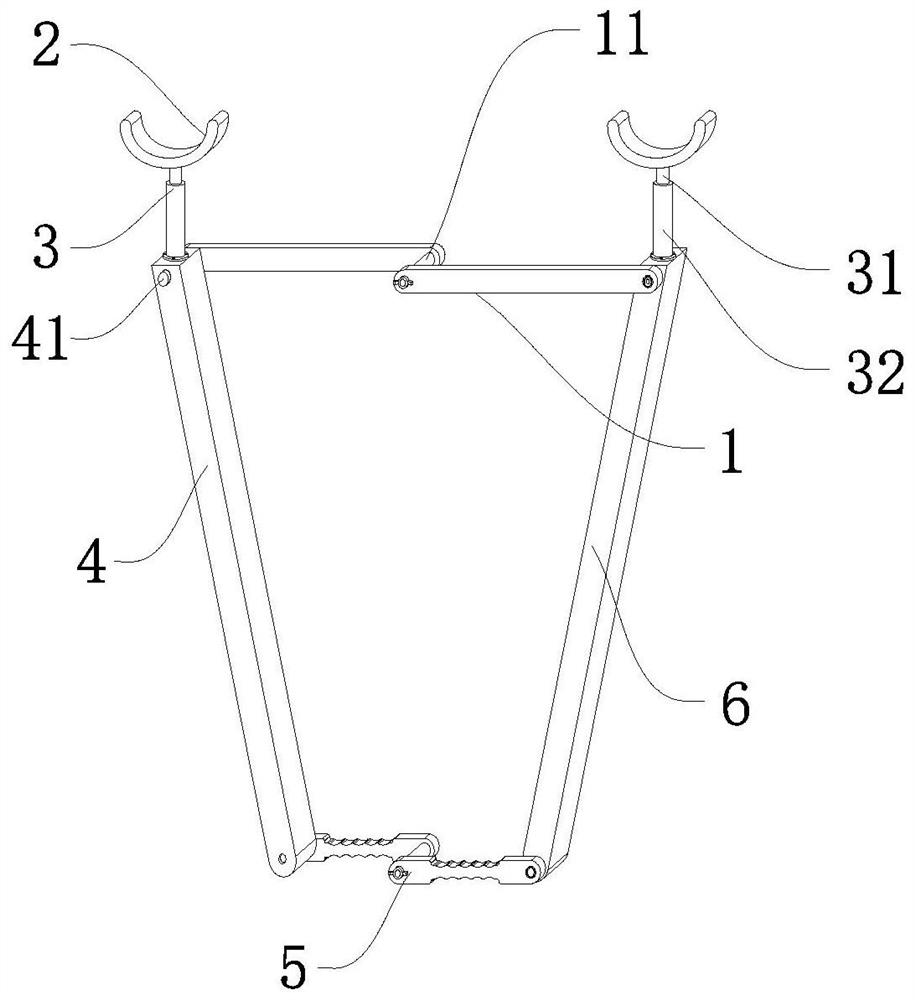

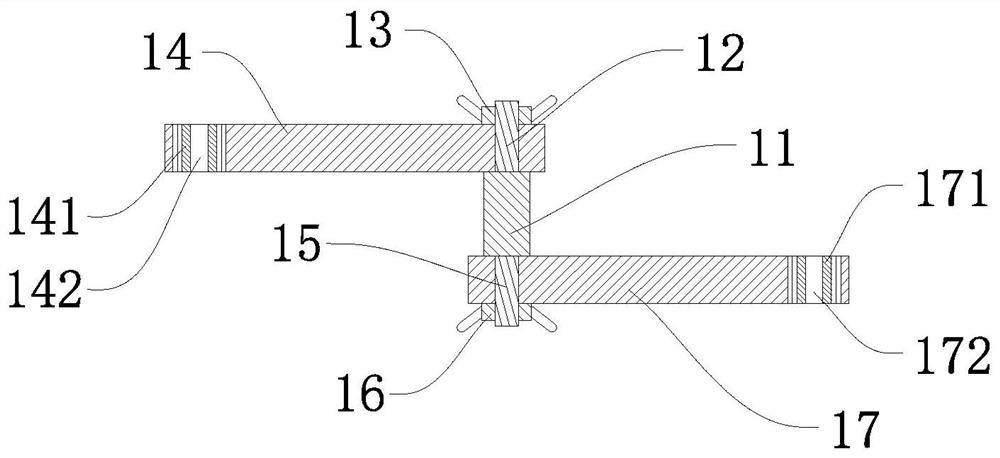

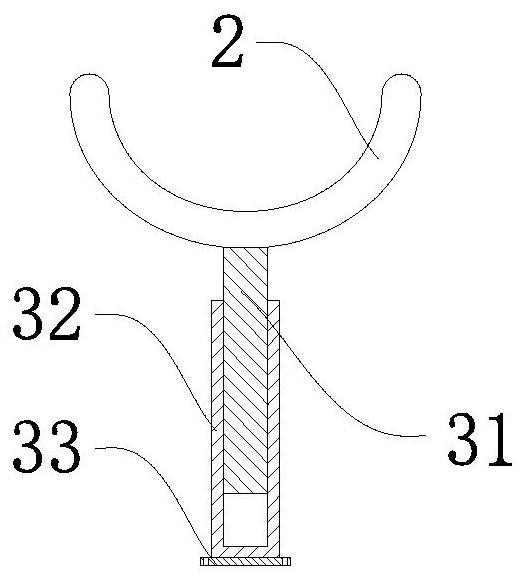

[0033] The specific embodiment, at first the first insertion rod 12 of the rear end of the first straight rod 11 penetrates the first cross bar 14, and then the first insertion rod 12 is threadedly connected with the first wing nut 13, and the first straight rod 11 Fasten the installation with the first cross bar 14, then pass the second insertion rod 15 at the front end of the second straight rod 51 through the second cross bar 17, and then make the second insertion rod 15 and the second wing nut 16 threaded , the first straight bar 11 and the second cross bar 17 are fastened and installed to realize the assembly of the adjustment assembly 1, and then the third inserting rods 52 at both ends of the second straight bar 51 respectively penetrate the two handle plates 54, and then The third plunger 52 is threaded with the third butterfly nut 53, and the second straight rod 51 is fastened and installed with the two handle plates 54 to realize the assembly of the push hand part 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com