Abnormality sensing apparatus, abnormality sensing method, and abnormality sensing program

A detection method and anomaly detection technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of not keeping fault data and difficult to use abnormal detection of equipment status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

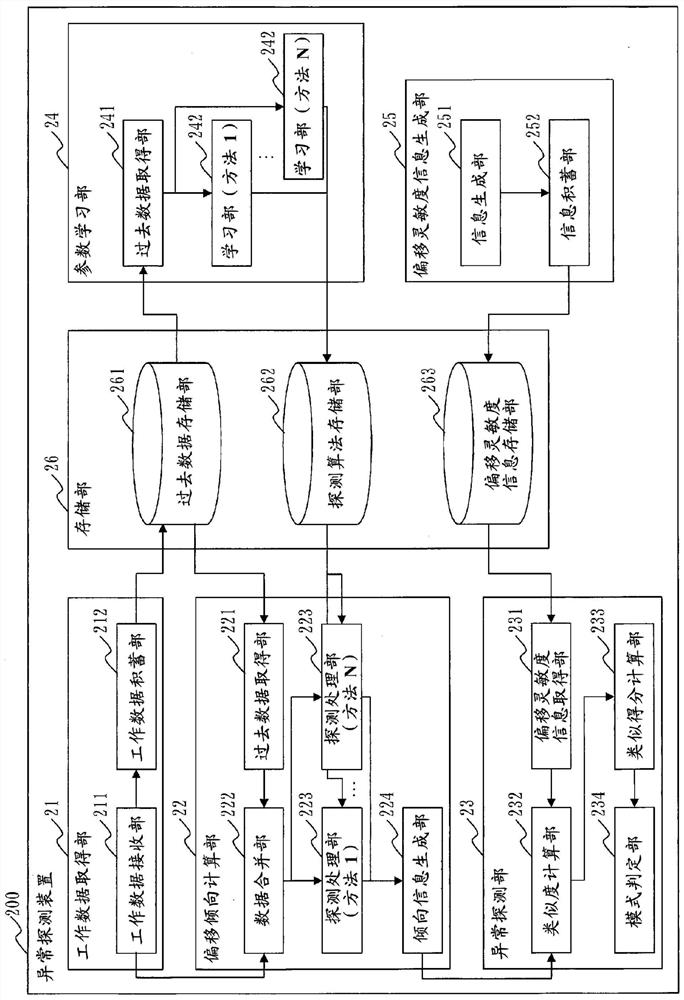

[0039] ***Description of structure***

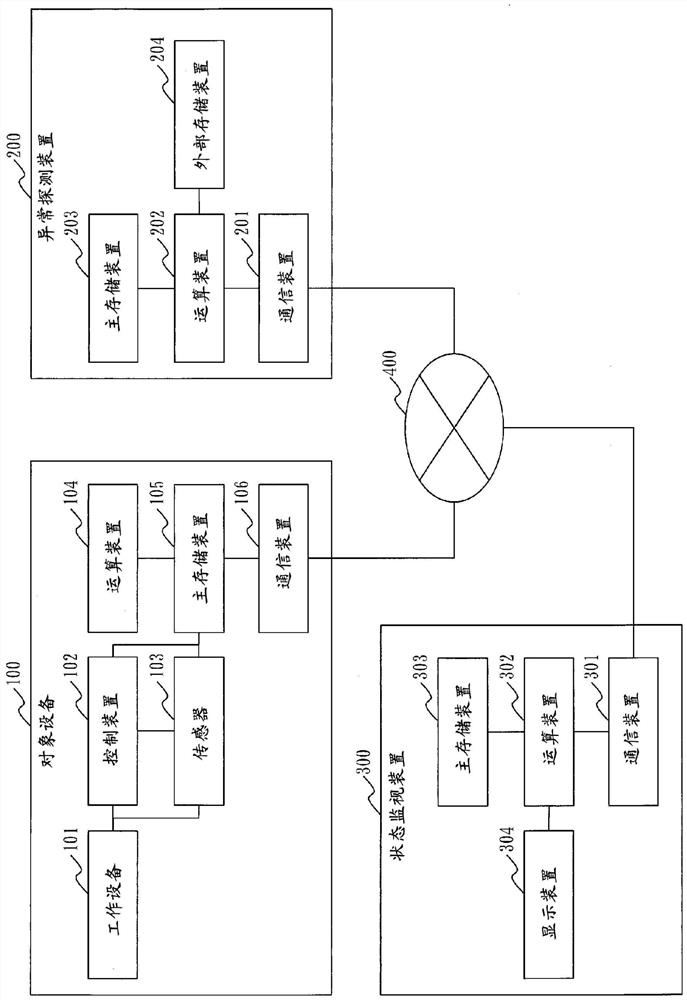

[0040] refer to figure 1 , and the hardware configuration of the abnormality detection system 1 according to Embodiment 1 will be described.

[0041] The abnormality detection system 1 includes a target device 100 , an abnormality detection device 200 , and a state monitoring device 300 . The target device 100, the abnormality detection device 200, and the status monitoring device 300 are connected via a network 400 such as a LAN (Local Area Network). The abnormality detection device 200 and the state monitoring device 300 may be a server with a physical entity or may be constituted by a cloud. Network 400 may also be a virtual network.

[0042] The target device 100 is a device to be targeted for abnormality detection.

[0043] The target device 100 includes hardware such as an operating device 101 , a control device 102 , a sensor 103 , an arithmetic device 104 , a main storage device 105 , and a communication device 106 .

[0044...

Deformed example 1

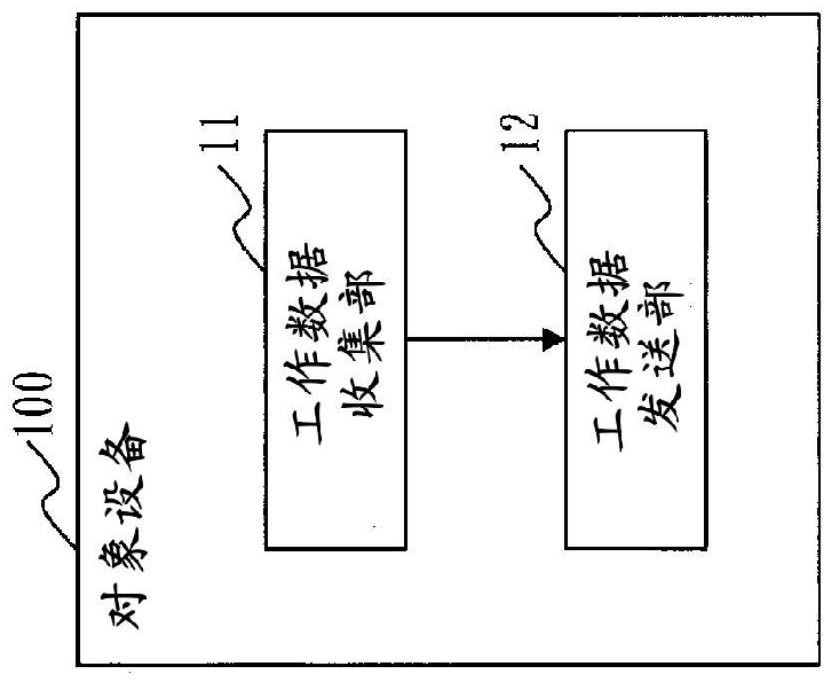

[0147] In Embodiment 1, the operation data collection unit 11, the operation data transmission unit 12, the operation data acquisition unit 21, the deviation tendency calculation unit 22, the abnormality detection unit 23, the parameter learning unit 24, the deviation sensitivity information generation unit 25, the result The functions of each part of the receiving unit 31 and the result output unit 32 are realized by software. However, as Modification 1, the functions of the above-mentioned components may also be realized by hardware. Regarding this Modification 1, points different from Embodiment 1 will be described.

[0148] refer to Figure 15 , the hardware configuration of the abnormality detection system 1 according to Modification 1 will be described.

[0149] In the case where the functions of the above-mentioned respective parts are realized by hardware, the target device 100 includes an electronic circuit 107 instead of the computing device 104 and the main storag...

Deformed example 2

[0154]As Modification 2, some functional constituent elements may be realized by hardware, and other functional constituent elements may be realized by software.

[0155] The computing devices 104, 202, and 302, the main storage devices 105, 203, and 303, and the electronic circuits 107, 205, and 305 are called processing circuits. That is, the functions of the above-mentioned parts are realized by the processing circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com