Production process convenient for manufacturing superfine slag powder

A production process and slag micro-powder technology, which is applied in grain processing, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as increasing the cleaning workload of staff, easy accumulation and residue of slag, and lack of repeated grinding of steel slag. , to avoid accumulation and easy residue, improve the quality of mineral powder, and strengthen the effect of high quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

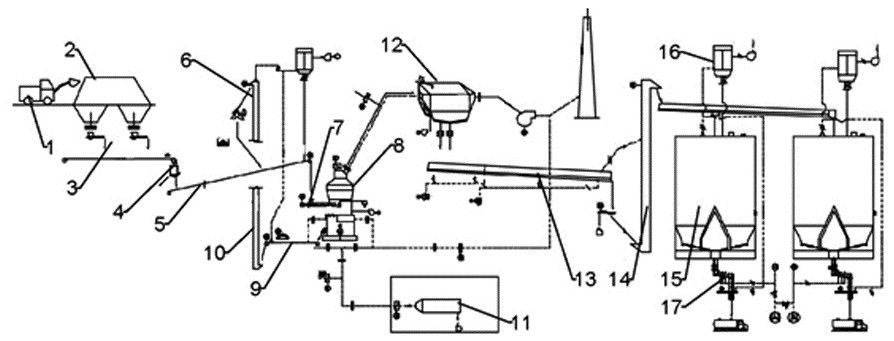

[0030] Example 1: see Figure 1-4 , a kind of production technology that is convenient to slag fine powder manufacture, comprises the following steps:

[0031] Step 1. First, the steel slag is shoveled into the feeding hopper 2 by the loader 1, and the steel slag in the feeding hopper 2 is weighed and measured through the meter 3 at the bottom of the feeding hopper 2, and the model of the meter 3 is HHSM103; The weighed and measured steel slag falls on the conveyor belt of the belt conveyor 5 after being screened by the cylindrical sieve 4, and the model of the belt conveyor 5 is PKD5060;

[0032] Step 2, the steel slag is transported to the screw feeder 7 by controlling the belt conveyor 5. The model of the screw feeder 7 is LS500. Dust removal operation, the model of the bag filter 6 is LY-836; the steel slag is conveyed into the vertical mill 8 by controlling the screw feeder 7, and the model of the vertical mill 8 is HLM;

[0033] Step 3. Send high-temperature flue gas a...

Embodiment 2

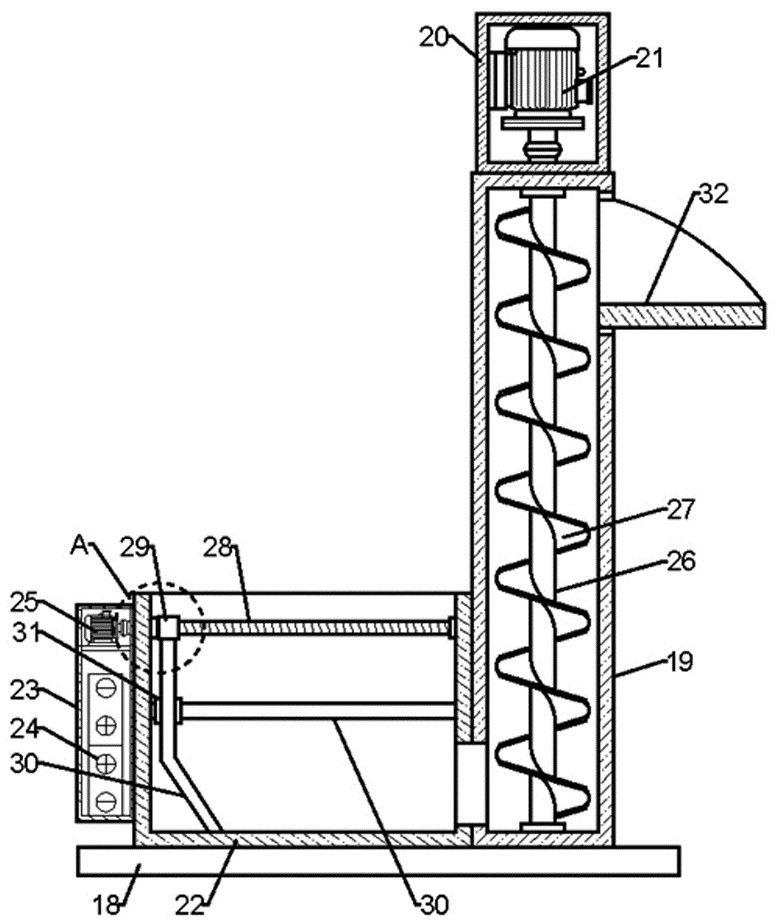

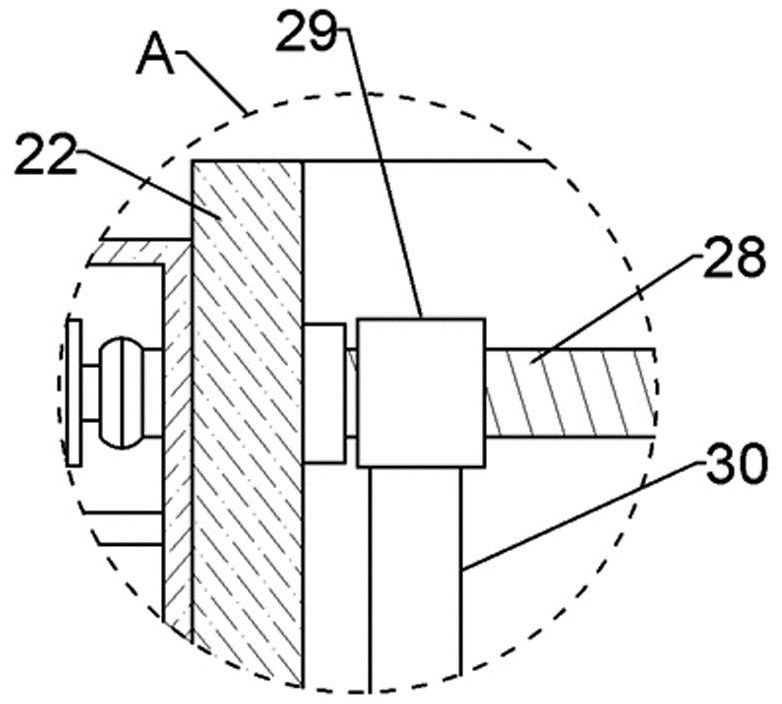

[0042] Embodiment 2: In this embodiment, the present invention also proposes a method for using the finished hoist, including the following steps: first, the first motor 21 and the second motor 25 are electrically connected to the storage battery 24 respectively through wires, and After the powder falls into the collection box 22, the mineral powder enters the conveying cylinder 19 through the feed port, and the rotating rod 26 is driven to rotate by controlling the first motor 21. The rotation of the rotating rod 26 is convenient to drive the spiral lifting blade 27 to carry out Lifting, through the lifting of the mineral powder, it is convenient to make the mineral powder fall into the finished product bin 15 through the discharge hopper 33 in the discharge port; by controlling the second motor 25 to drive the lead screw 28 to rotate, the rotation of the lead screw 28 is convenient to make the threaded cylinder 29 Transverse movement on the rod body;

[0043] The lateral mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com